Data driving threshold value noise-reduction method for rotary machine vibration signals

A vibration signal and rotating machinery technology, applied in the field of noise reduction, can solve the problems of difficulty in accurately setting the threshold value, inability to effectively extract fault features, large noise components, etc., to achieve good robustness, good noise reduction effect, signal flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

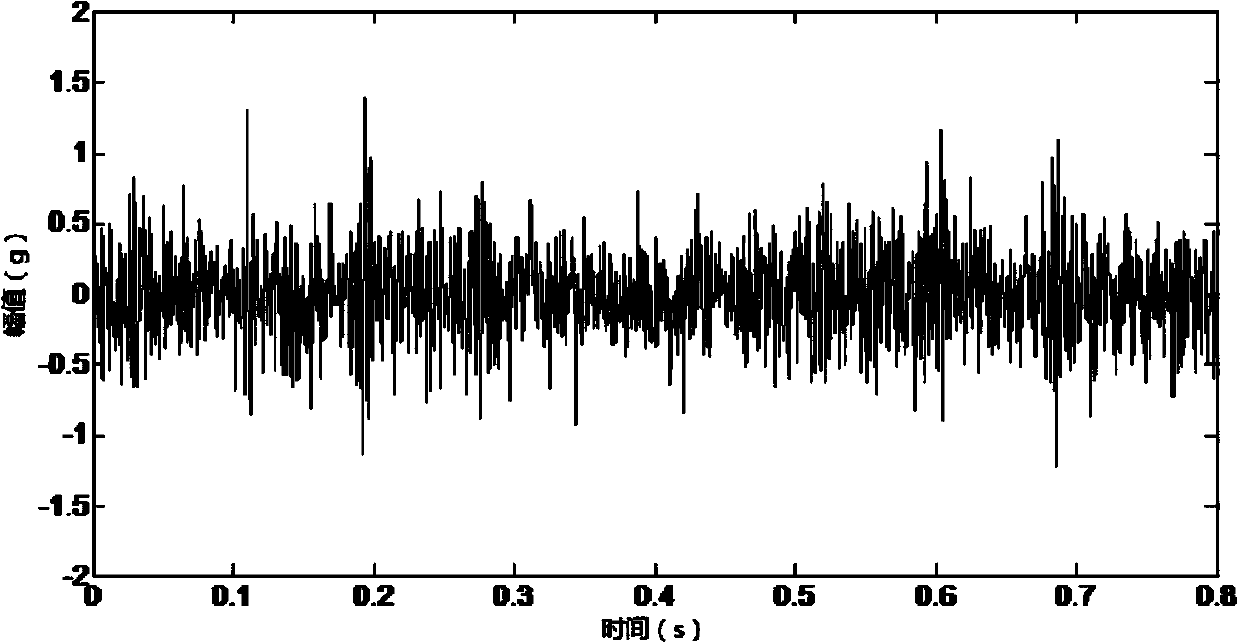

[0058] Fault diagnosis is carried out on the abnormal vibration of the dust removal fan to verify the effectiveness of the invention. The dust removal fan is driven by a motor and used to remove dust and impurities in the steelmaking process to ensure the quality of steel. The vibration signal is collected at the bearing seat, the sampling frequency is 5120Hz, and the rotation frequency of the fan is 12.5Hz. The collected vibration signal is as follows: Figure 7 shown.

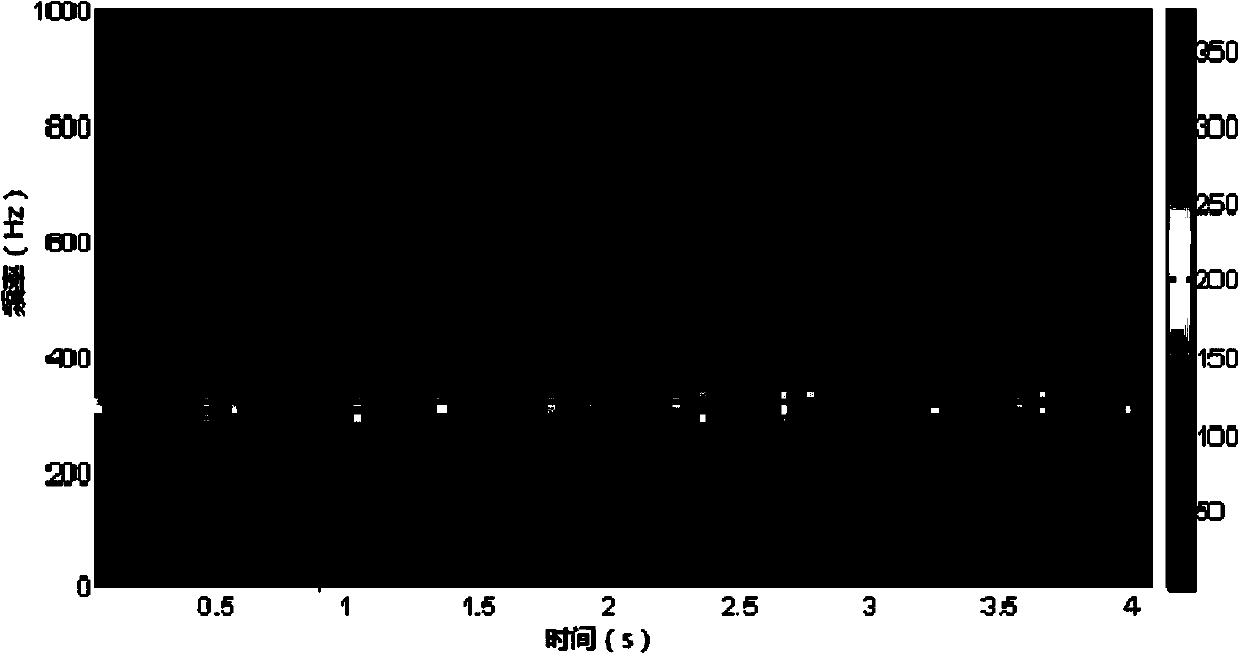

[0059] Using formula (1) to carry out wavelet transform on the collected vibration signal, and obtain the vibration signal of each frequency band. Then the short-time Fourier transform is performed on the vibration signals of each frequency band by formula (2), and its power spectral density is calculated. Taking the vibration signal on the fifth frequency band as an example, its power spectral density is as follows: Figure 8 shown.

[0060] The power spectral density of the vibration signal in the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com