Packaging structure applied to long-pulse-width and high-power semiconductor laser

A packaging structure and laser technology, applied in the laser field, can solve problems such as heat dissipation differences, and achieve the effects of alleviating stress and strain differences, improving heat dissipation efficiency, and reducing temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

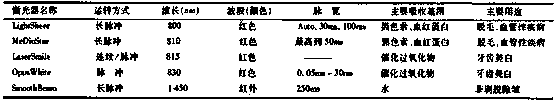

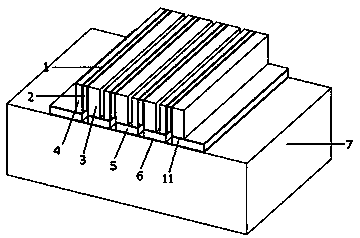

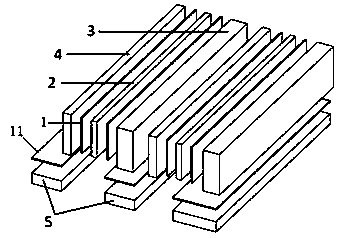

[0032] like figure 1 As shown, a high-power semiconductor laser packaging structure applied to long pulse width, including high-temperature hard solder 1, hard solder 11, semiconductor laser bar 2, p-plane sub-heat sink 3, n-plane sub-heat sink 4, electrical insulation Heat sink 5, soft solder 6 and heat sink 7, such as figure 2 As shown, the large surfaces of the n-plane sub-heat sink 4, the semiconductor laser bar 2 and the p-plane sub-heat sink 3 are stacked in sequence, and then the high-temperature hard solder 1 is used for high-temperature reflow soldering between each stacked surface. It is formed into a bar stack unit, and the electrical insulation heat dissipation is stacked on the long side of the same side of the n-plane sub-heat sink 4 and the p-plane sub-heat sink 3 in the above-mentioned welded bar stack unit. sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com