A melt processable composition and method of making

A technology of melt processing and composition, applied in the field of melt-processed compositions, can solve problems such as hindering the application of materials that can be melt-processed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

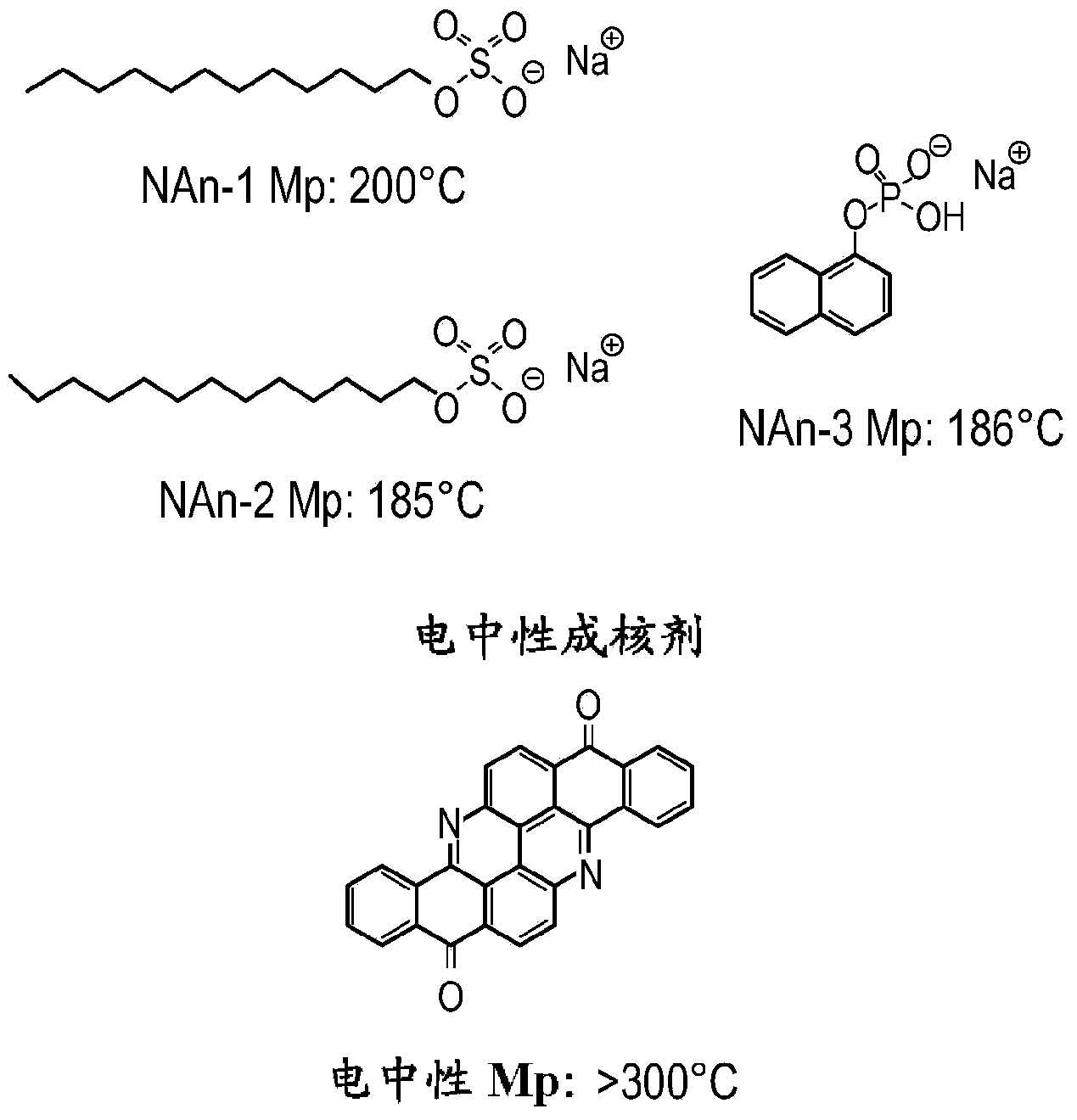

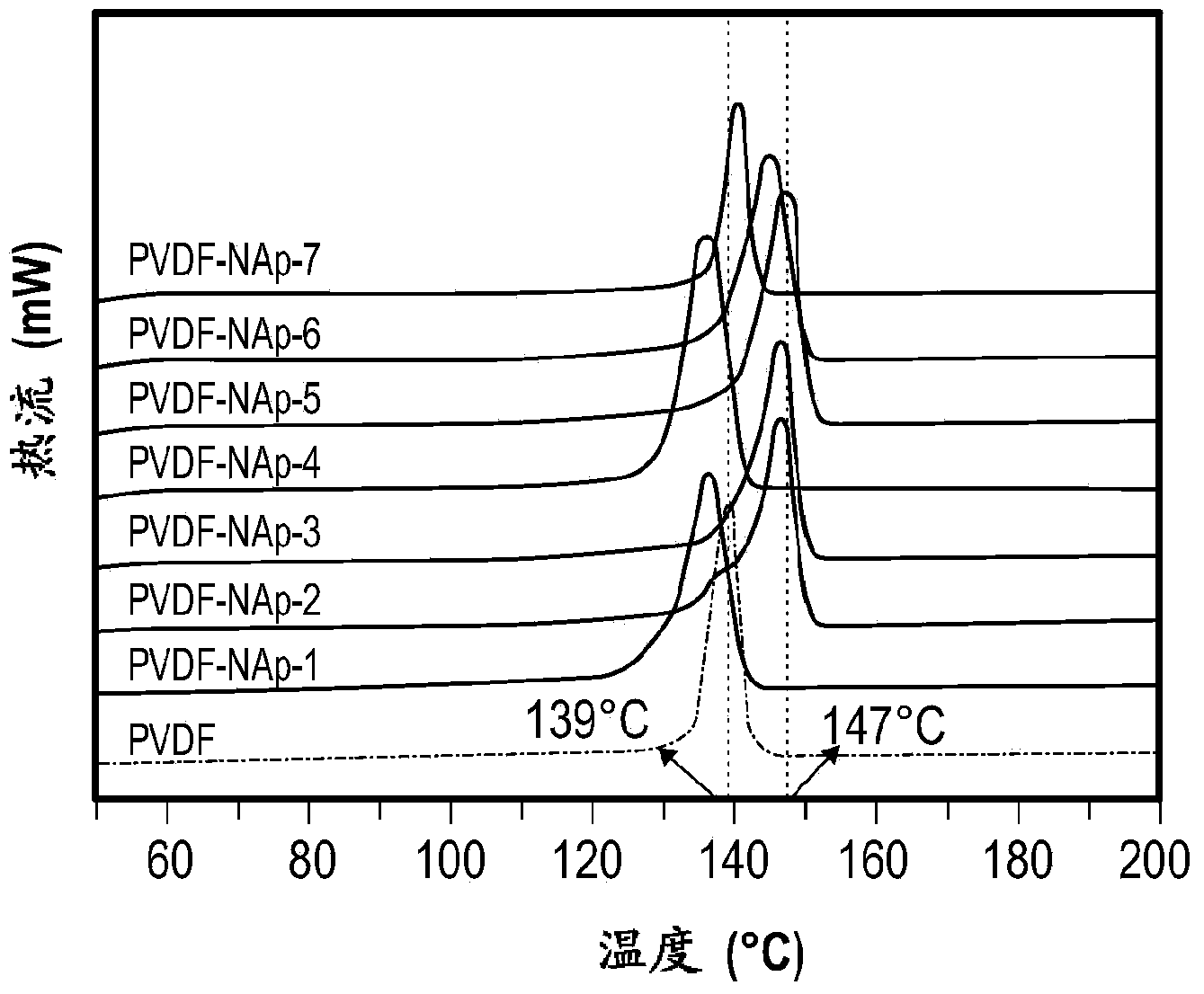

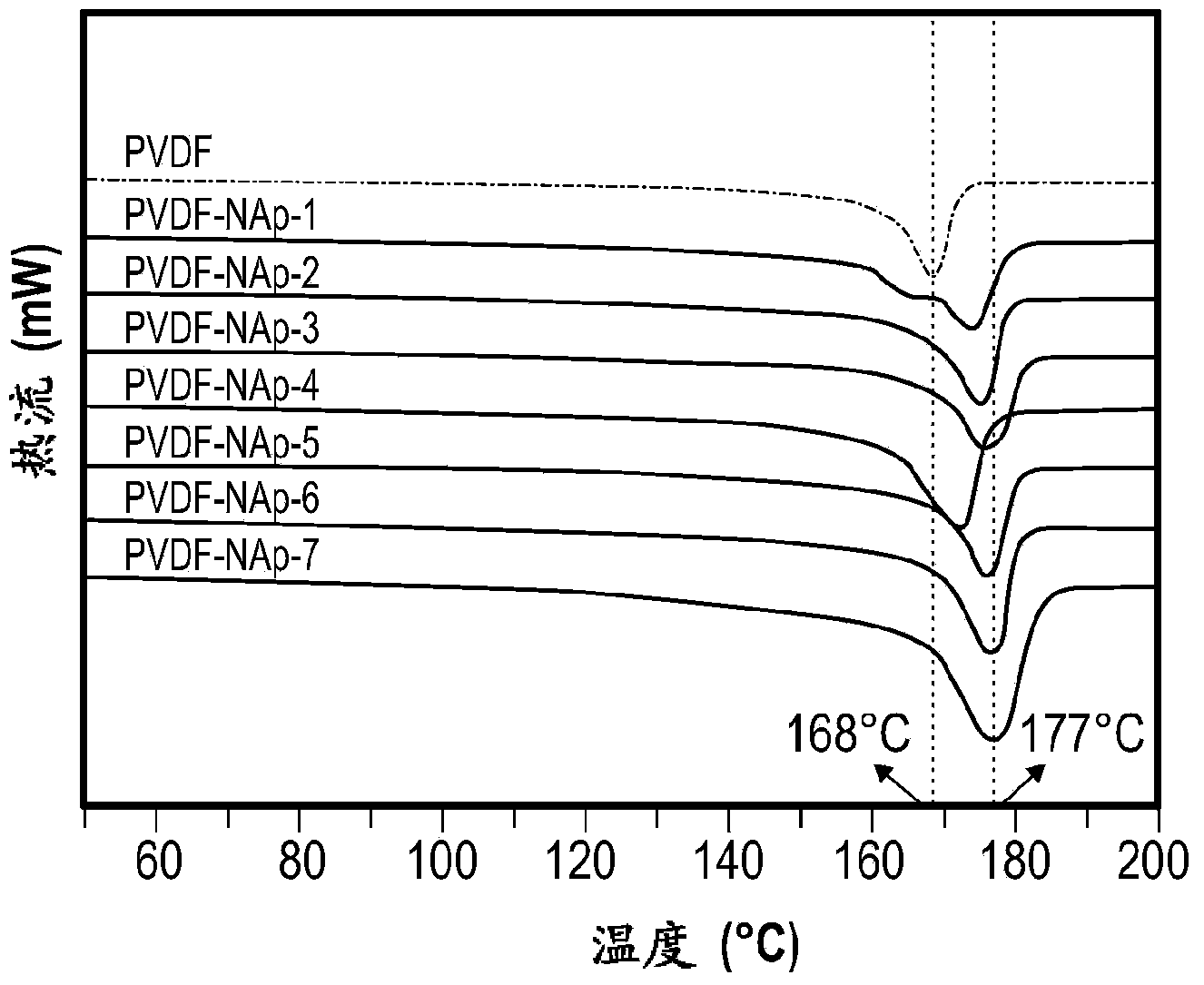

[0041] Melt processable polymers are - brand fluoropolymer, which is PVDF commercially available from Arkema Inc., King of Prussia, Pennsylvania, USA. Three types of nucleating agents were melt blended to the PVDF. First, using electropositive nucleating agents (NAp) tetrabutylphosphonium hexafluorophosphate (NAp-1), ethyltriphenylphosphonium bromide (NAp-2), n-heptyltriphenylphosphonium bromide (NAp -3), N-acetonylpyridinium bromide (NAp-4), 1-butyl-1-methylpyrrolidinium bromide (NAp-5), tetrabutylammonium hydrogensulfate (NAp-6) and Triphenylsulfonium tetrafluoroborate (NAp-7) was used without further purification. Second, use negatively charged nucleating agents (NAn) sodium lauryl sulfate (NAn-1), sodium n-tridecyl sulfate (NAn-2), 1-naphthyl phosphate monosodium salt monohydrate (NAn-3 ), and third, use the charge neutral nucleating agent Flavanthone (charge neutral). The nucleating agent is selected to have a melting temperature near or above the melting temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com