A heat pipe heat transfer type gas-liquid-solid three-phase loop reactor

A loop reactor, gas-liquid-solid technology, applied in the fields of energy engineering and chemical engineering, can solve problems such as difficult to effectively remove heat, difficult to maintain uniform temperature distribution of the reactor, etc., to achieve stable operation, easy adjustment and maintenance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

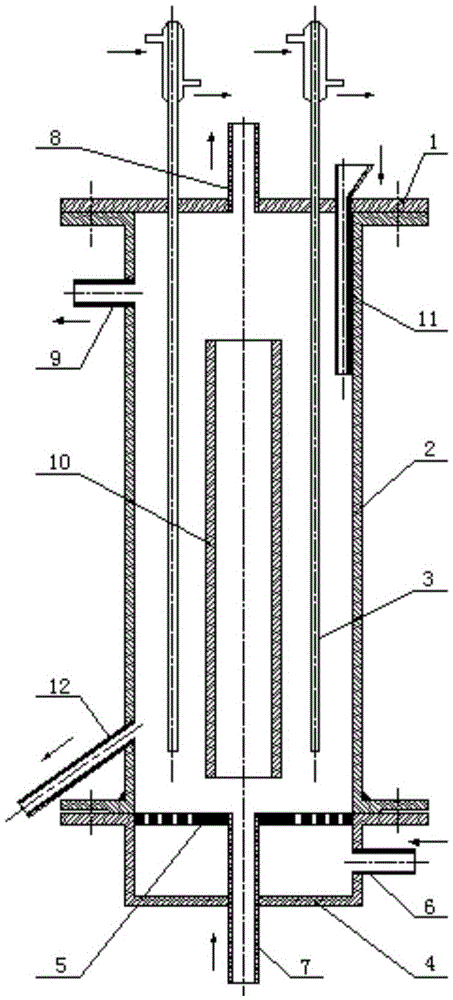

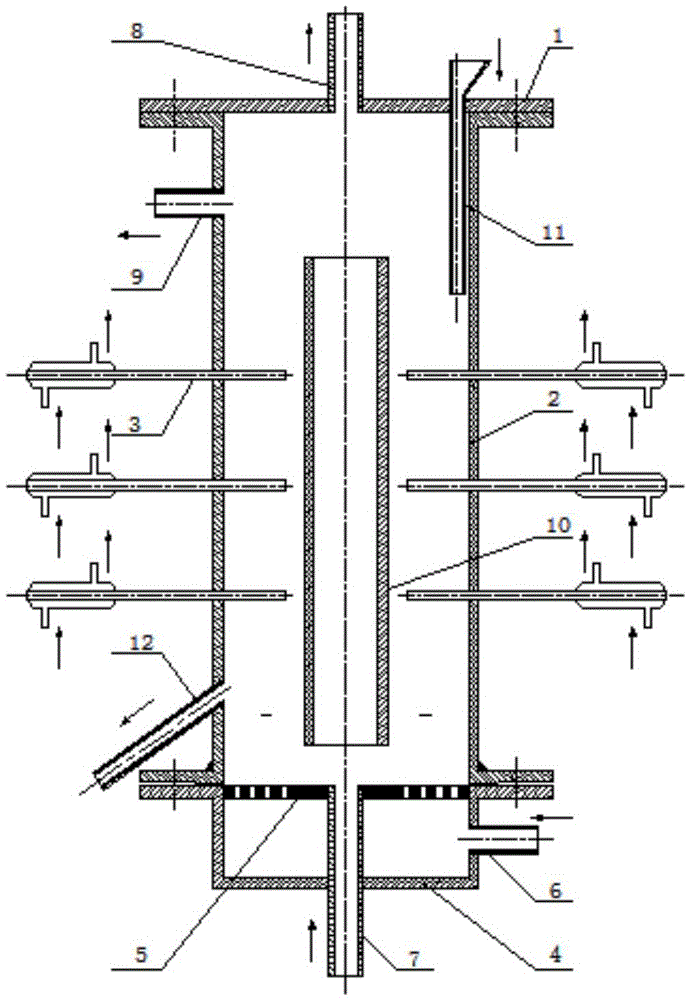

[0026] Such as figure 1 with figure 2 As shown, a heat pipe heat transfer type gas-liquid-solid three-phase loop reactor includes a three-phase loop reactor body and a heat transfer device.

[0027] The three-phase loop reactor body includes an upper head 1, a tower body 2, a lower head 4, an auxiliary fluid distributor 5, an auxiliary fluid feed pipe 6, a spray inlet pipe 7, an air outlet pipe 8, and a liquid outlet pipe 9 , Riser 10, solid feed pipe 11 and solid discharge pipe 12. The upper head 1 is connected to the tower body 2 by bolts, the lower head 4 is also connected to the tower body 2 by bolts, the riser 10 is fixed in the tower body 2 by a bracket, and the riser 10 and the jet air intake pipe 7 are in the same center line, the diameter of the riser 10 is greater than or equal to the diameter of the jet inlet pipe 7; The space between them forms an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com