Full-automatic ball feeding system

A fully automatic, steel ball technology, used in grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

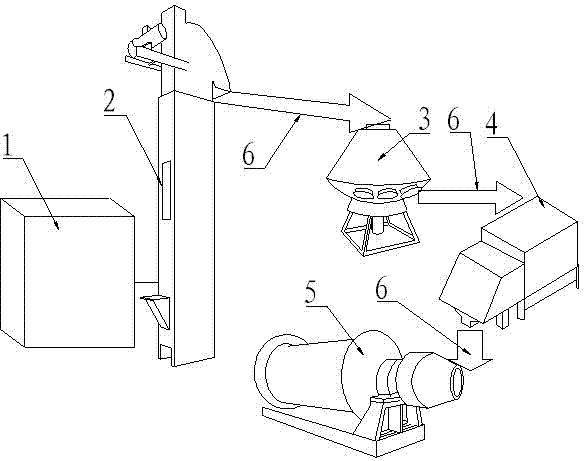

[0016] Such as figure 1 with figure 2 The fully automatic ball adding system shown is composed of a ball storage bin (1), a steel ball hoist (2), a ball distributor (3), a ball adding machine (4) and a ball mill (5); the ball storage bin The ball outlet of (1) is connected to the steel ball hoist (2), and the steel ball hoist (2) and the ball distributor (3), the ball adding machine (4) and the ball mill (5) pass through the pipeline (6) connect.

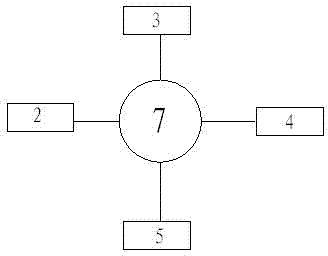

[0017] As mentioned above, the steel ball hoist (2), the ball distributor (3), the ball adding machine (4) and the ball mill (5) are all connected to the PLC controller (7).

[0018] The main design idea of the full-automatic ball adding system for grinding is to put the steel balls into the designated ball storage bin (1) after they enter the dressing plant. (2), lift the steel ball to a certain height, and enter the ball distributor (3) through the yo-ball pipe (6); the ball distributor (3) rotates and distributes the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com