Modular Multi-Line Microjet Nebulizer

A micro-fluidic and modular technology, applied in the field of atomizers, can solve the problems of material and energy waste, hanging on the wall, etc., and achieve the effect of improving production capacity, reducing manufacturing and maintenance costs, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

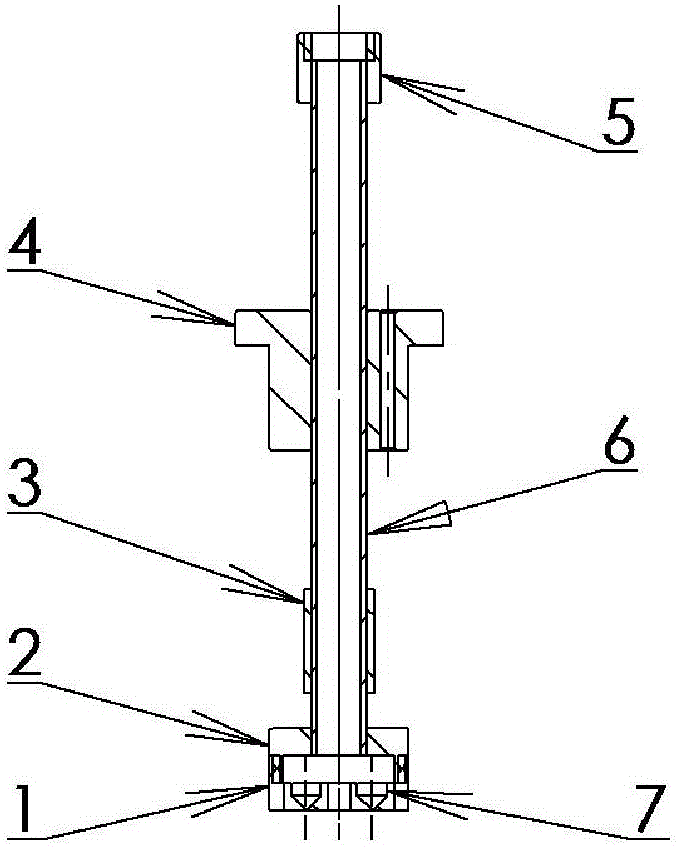

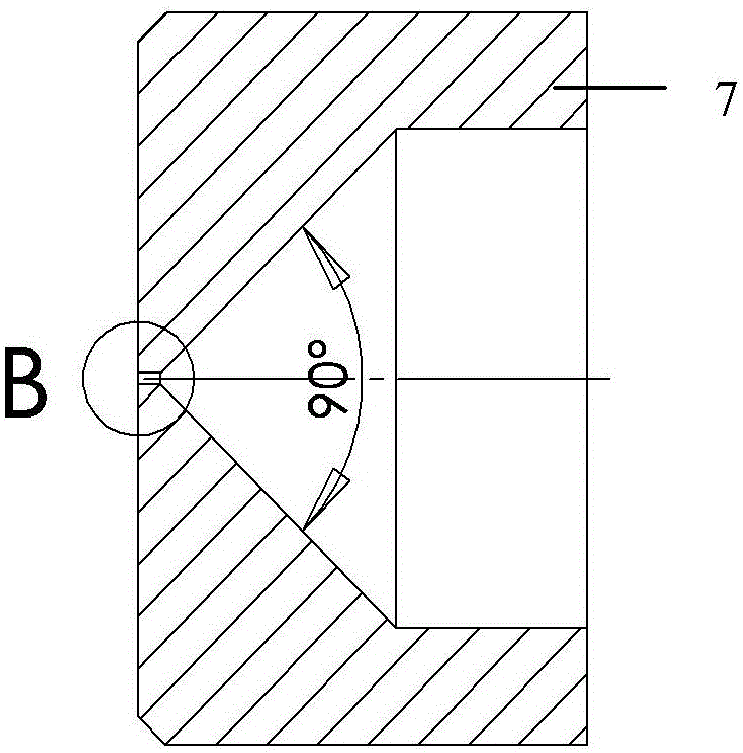

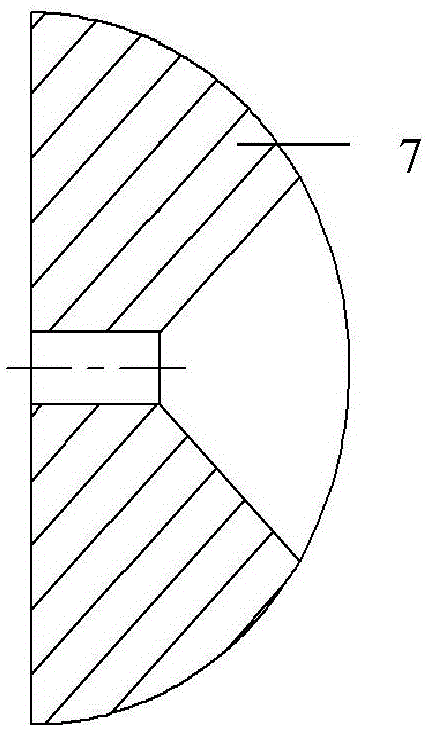

[0016] Such as Figure 1~4 As shown, the present invention is provided with a first nozzle 1 , a second nozzle 2 , a glass tube 6 , an adapter 5 , a piezoelectric ceramic tube 3 and a fixing assembly 4 . The first nozzle 1 and the second nozzle 2 are installed at the lower end of the glass tube 6, and at least two nozzles 7 are evenly installed on the inner circumference of the first nozzle 1 and the second nozzle 2; the connector 5 is provided with an internal thread and a gasket The connecting piece 5 is installed on the upper end of the glass tube 6, the connecting piece 5 is connected with the storage tank containing the material through an internal thread, and the connecting piece 5 is sealed by a sealing gasket; the piezoelectric ceramic tube 3 is arranged on the glass tube 6 In the lower part, the piezoelectric ceramic tube 3 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com