Automatic machining and feeding system for metal bars

A technology of metal rods and material boxes, applied in metal processing equipment, manufacturing tools, operating devices, etc., can solve the problems of insufficient coordination of workers, lower yield rate, high probability of misoperation, etc., to improve high temperature operation risk and production efficiency The effect of improving and reducing the chance of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solution of the present invention clearer, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

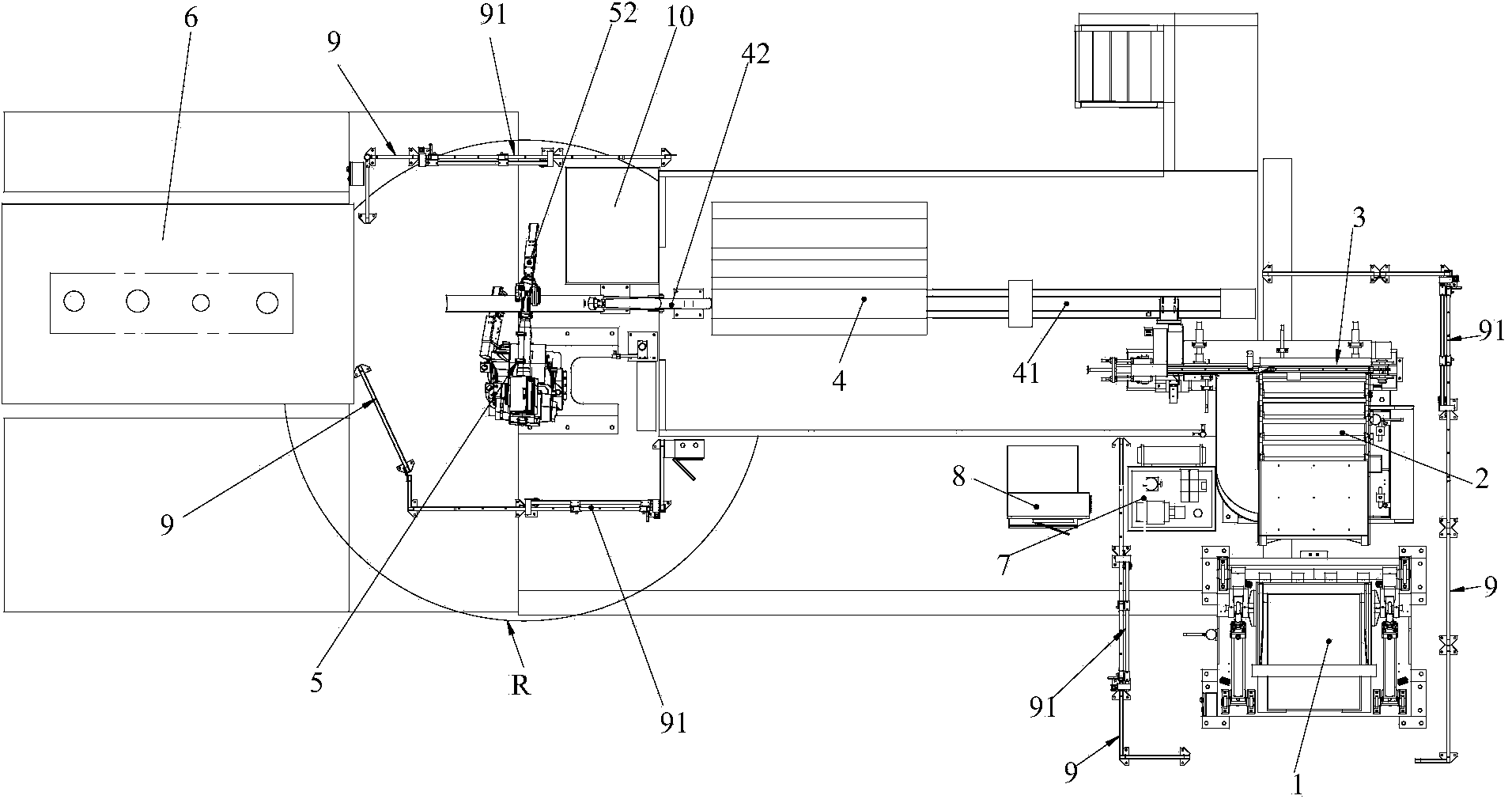

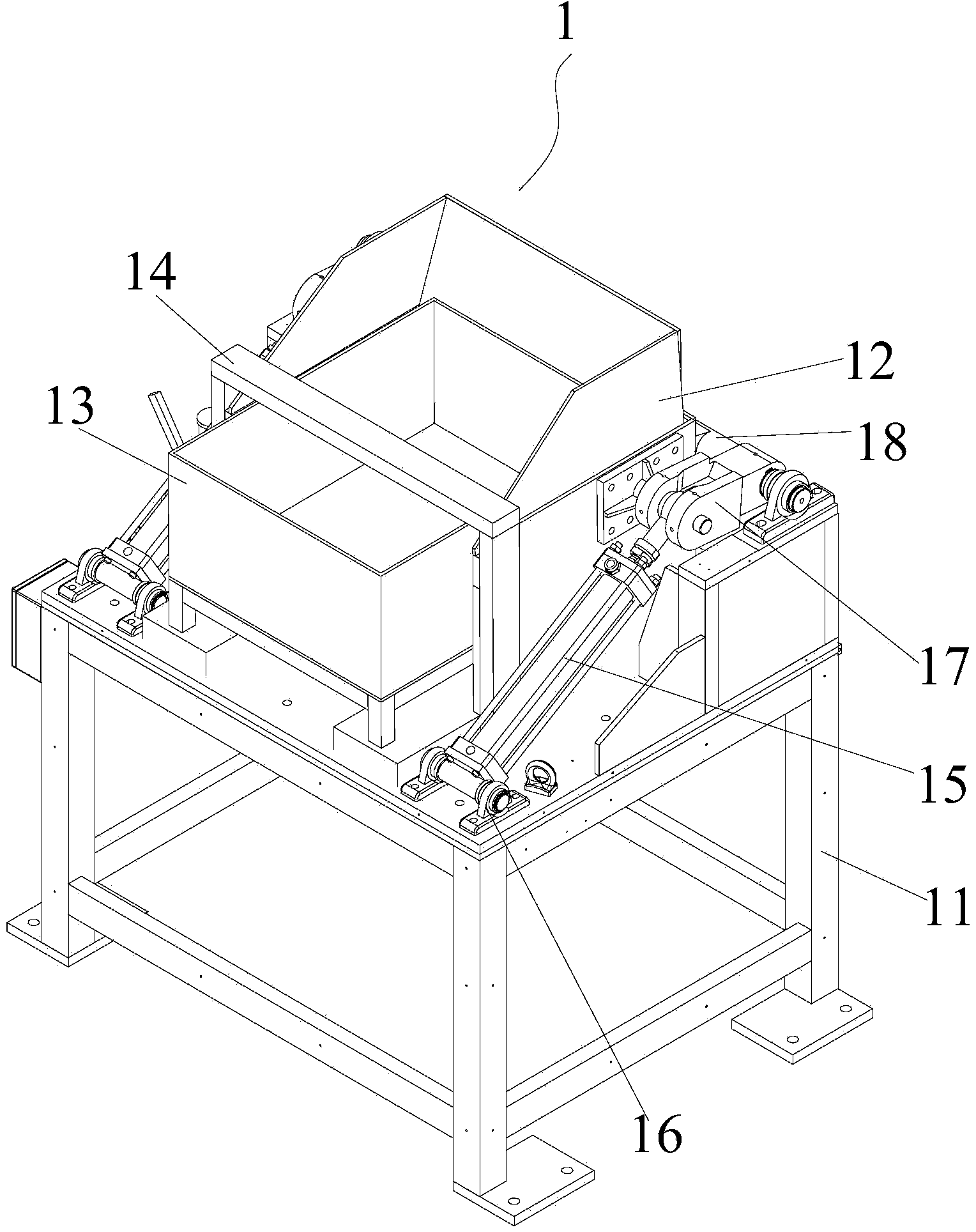

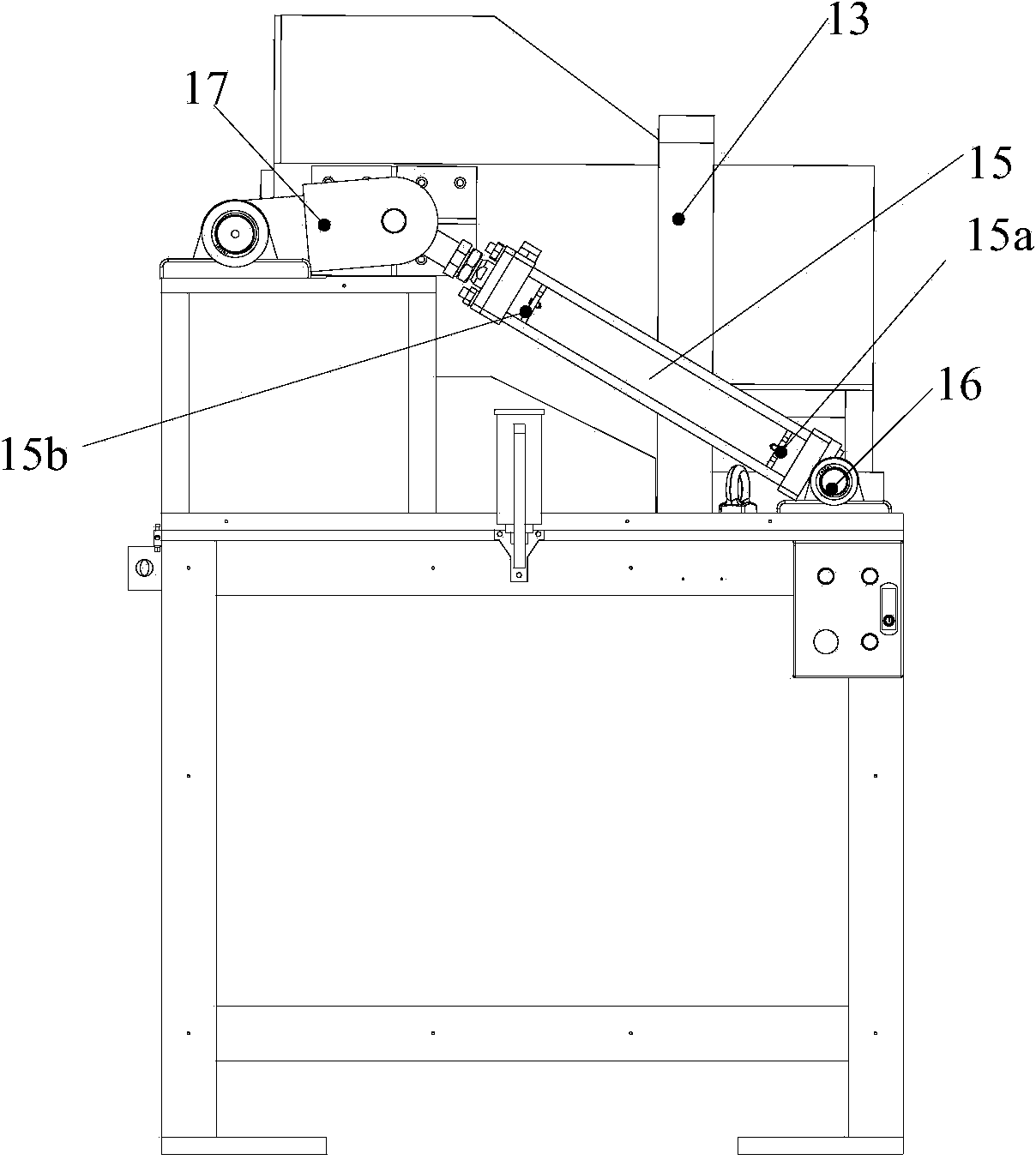

[0049] See Figure 1 ~ Figure 15 , The metal bar material automatic processing and feeding system in this embodiment includes the following components: flipping and dumping mechanism 1, monolithic arrangement mechanism 2, conveying detection mechanism 3, heating mechanism 4, robot 5, hydraulic station 7, control cabinet 8. , The robot 5 is set close to the forging press 6; the robot 5 is surrounded by a safety guardrail 9, the overturning and dumping mechanism 1, the whole material arrangement mechanism 2, the conveying detection mechanism 3 is also surrounded by a safety guardrail 9, and the safety guardrail 9 is provided There are 91 sliding doors. Wherein, the hopper of the material turning and unloading mechanism 1 is arranged close to the storage lifting hopper of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com