Splicer for splicing steel plates for shipbuilding

A splicing machine and steel plate technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient panel adjustment, impractical splicing of shipbuilding panels, complex structure, etc., and achieve strong practical performance and promotion value , Simple structure, light and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

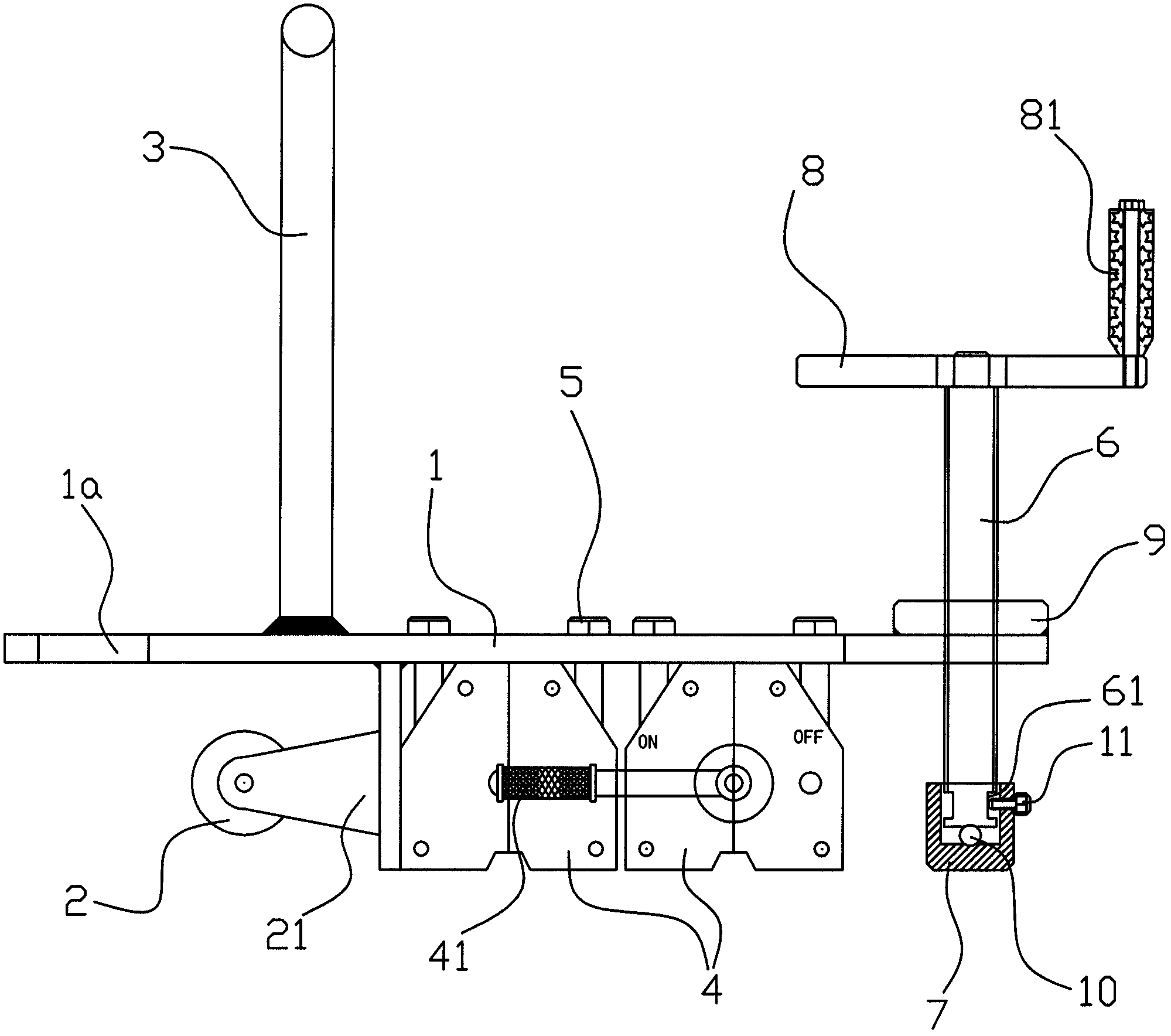

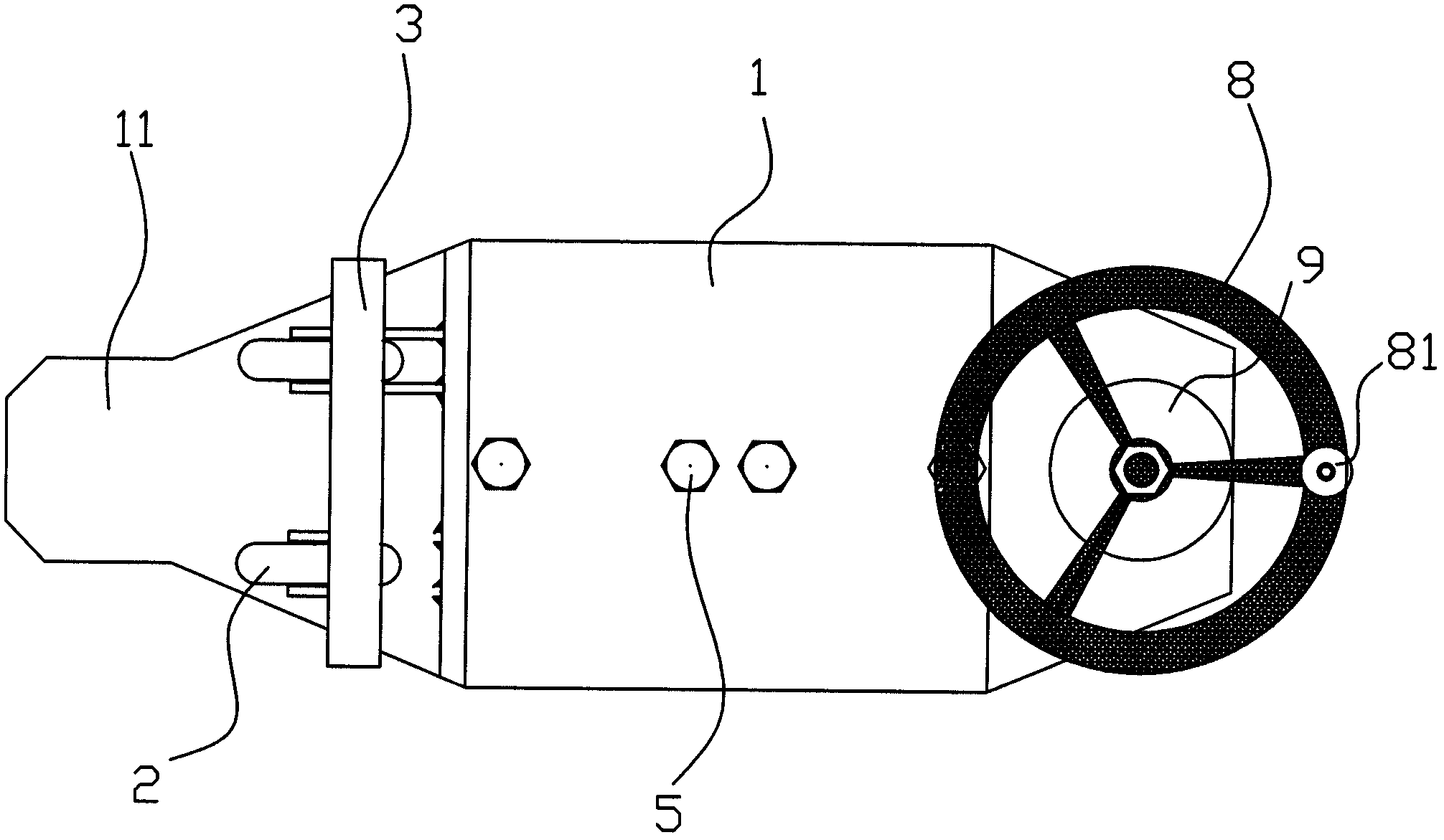

[0017] Such as figure 1 , 2 As shown, the splicing machine used for splicing steel plates in shipbuilding in this embodiment includes a frame, and the frame includes a fixed plate 1 with a moving wheel 2 at the bottom, and the fixed plate 1 is made of steel plates. The plate 1 is located on one side of the moving wheel 2 and is welded with a push-pull rod 3. There are two moving wheels 2, which are installed on the fixed plate 1 below the push-pull rod 3 through brackets 21, and the fixed plate 1 extends out of the moving wheel 2. A part of the footboard 1a shrinks to form a footboard 1a; a permanent magnet for absorbing the steel plate is fixed under the middle of the fixed plate 1, and a manual adjustment device for adjusting the height of the steel plate is provided on the other side of the fixed plate 1. The permanent magnet is two parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com