Processing method of automobile engine front cover

A technology of automobile engine and processing method, which is applied in the field of processing the front end cover of automobile engine, can solve the problems of workpiece deformation, high cost, and high cost of injection molding technology, achieve small fine grinding allowance, stable grinding amount, and reduce subsequent processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment, the present invention is further described:

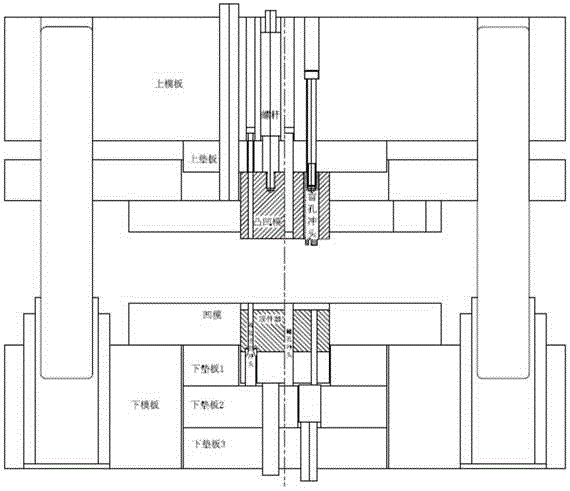

[0038] Such as Figure 2-4 The processing method of the shown parts includes the following steps:

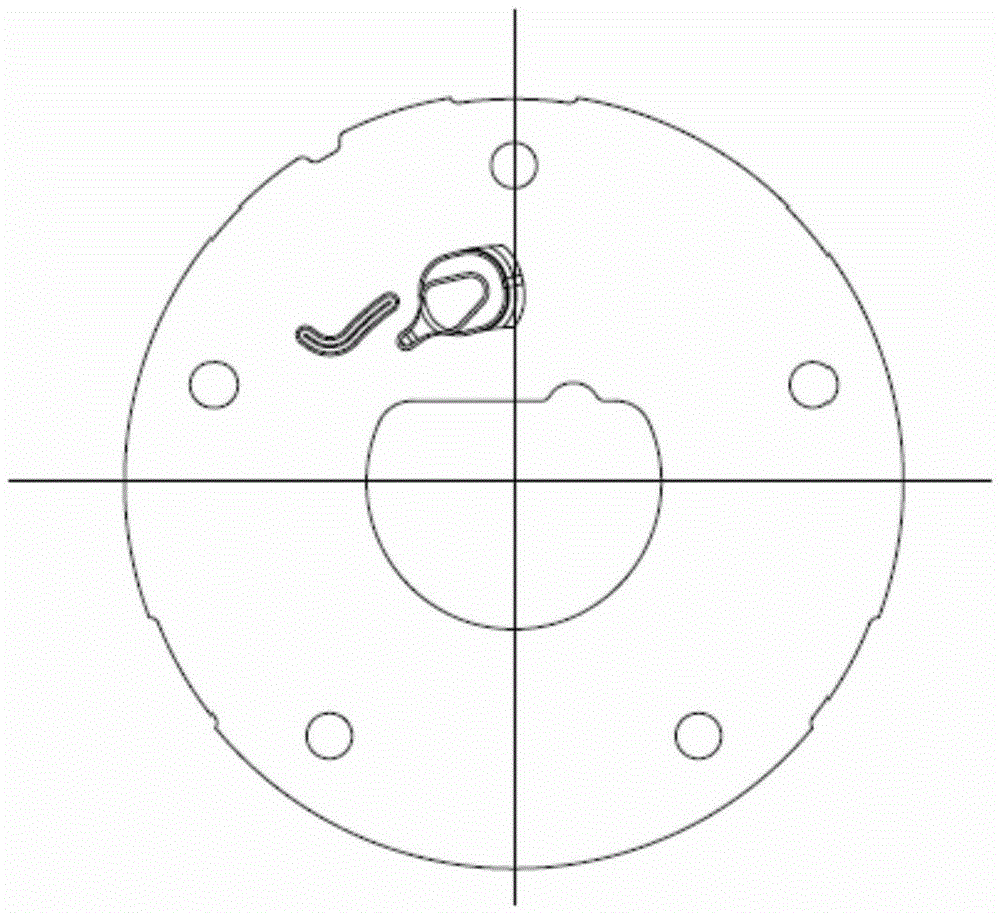

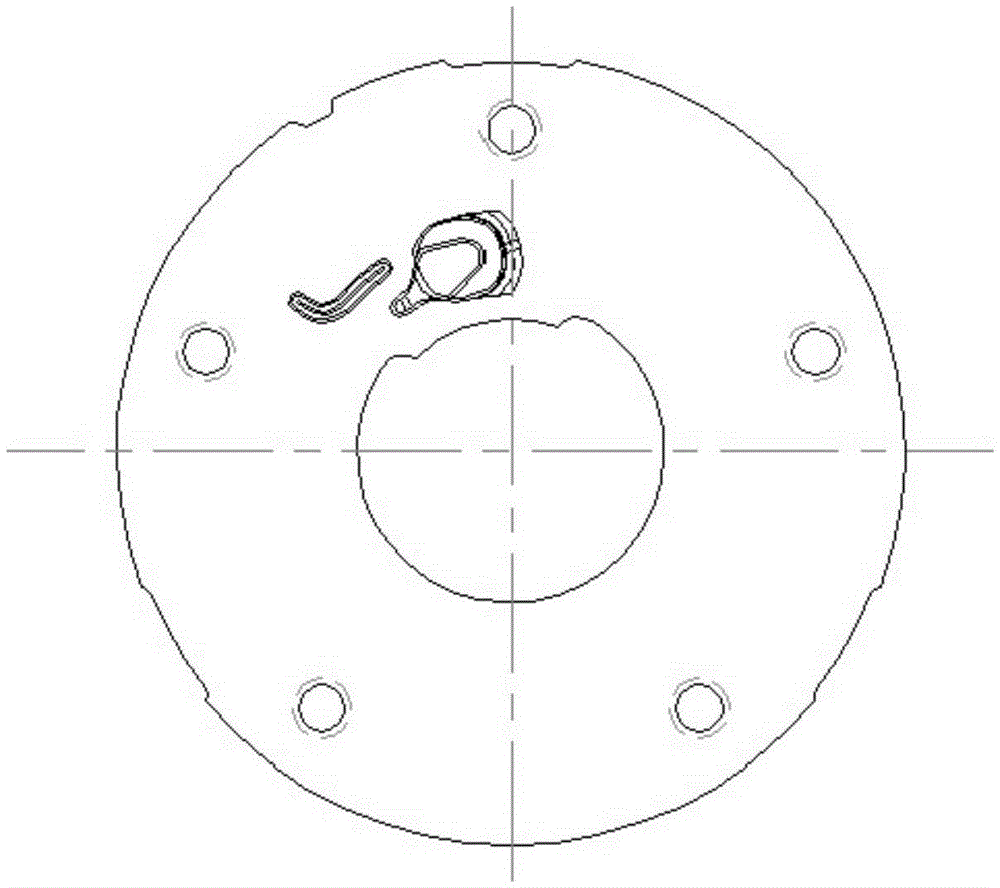

[0039] Firstly, the uncoiling and straightening machine is used to uncoil and straighten the raw material steel plate, and then the raw material steel plate is fine blanked to form a shaft hole in the center, and two blind holes are arranged next to the shaft hole, one is "L" shape, The other part is in the shape of a "table tennis racket", with a circular shape and five round holes evenly distributed in the circumferential direction. The structural diagram is as follows figure 1 As shown, in this step, when fine-blanking the shaft hole, a machining allowance of at least 2mm is reserved around the periphery, and the shape of the fine-blanking is a three-quarter circle with a notch, the side of the notch is a straight line, and the notch is facing the blind hole A machining allow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com