Double-motor multi-mode dynamic coupling driving assembly

A technology of power coupling and drive assembly, which is applied to electric power units, power units, control units, etc., and can solve the problems of power interruption, low power density, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

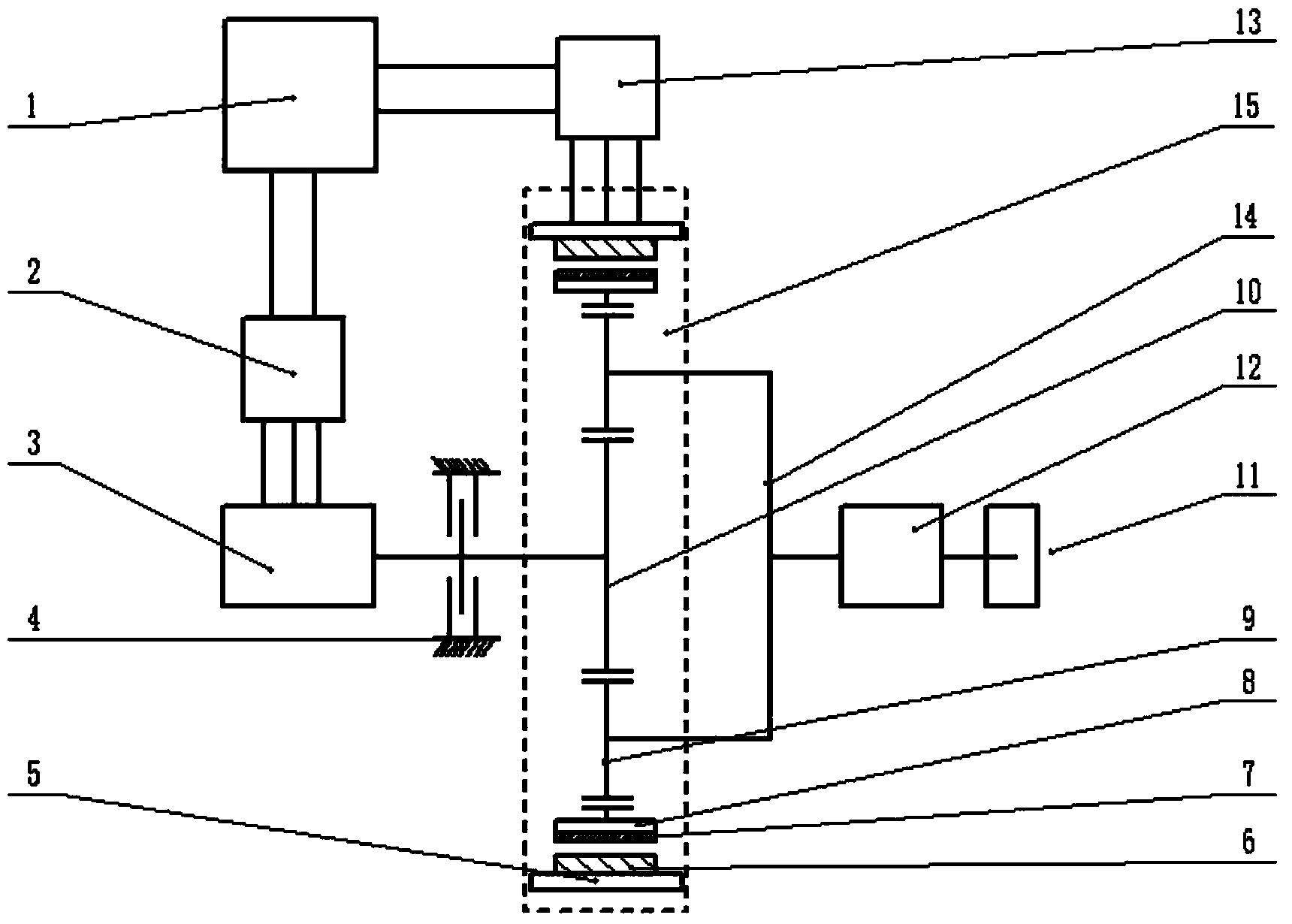

[0010] Now further illustrate in conjunction with accompanying drawing.

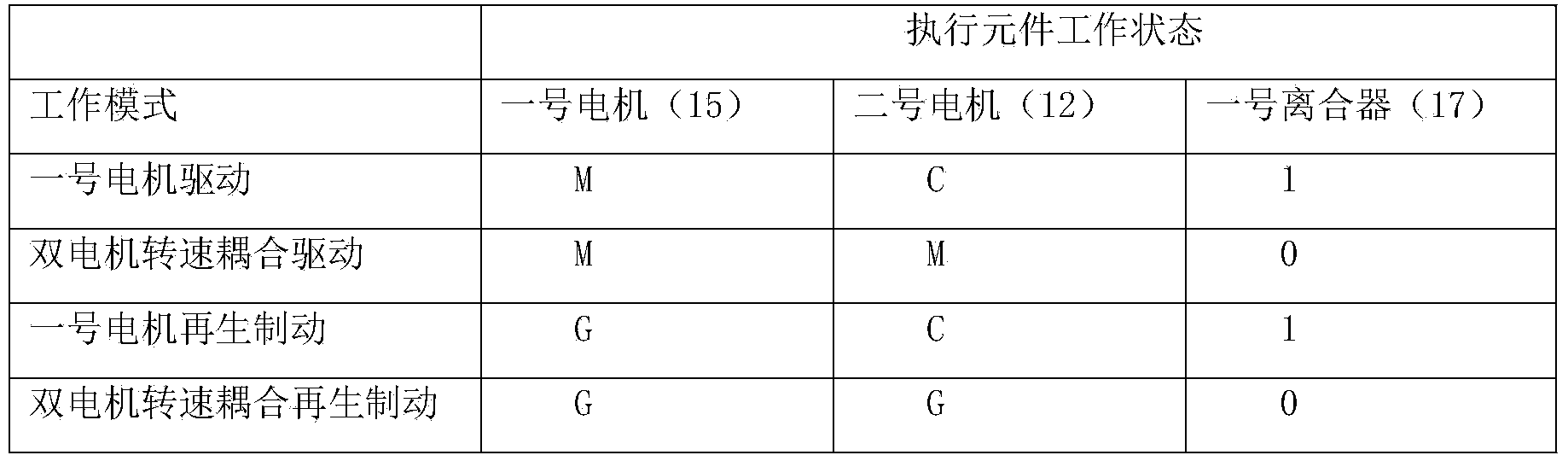

[0011] The present invention is composed of energy storage device (1), controller (2), and controller (13), No. 2 motor (3), locker (4), No. 1 motor (15), final reducer (12 ), and drive axle (11). Among them, the No. 1 motor (15) consists of a motor casing (5), a stator (6), a ring gear rotor (8), a magnetic steel (7), a planetary gear (9), a sun gear (10), and a planet carrier (14) composition. It is characterized in that the No. 1 motor (15) and the No. 2 motor (3) are coaxially arranged. The power of the No. 1 motor (15) is transmitted to the rotor ring gear (8) through the stator (6) and the magnetic field, and the power of the No. 2 motor (3) is transmitted to the sun gear (10) through the lock (4). The power of each motor is coupled to the planetary carrier (14) through the planetary row inside the rotor (8), and the power of the planetary carrier (14) is transmitted to the drive axle (11) throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com