Preparation method for TiO2/InVO4 composite porous micro-sphere

A technology of porous microspheres and microspheres, applied in chemical instruments and methods, vanadium compounds, titanium oxide/hydroxide, etc., can solve the problems of difficult recovery of nano-powders, avoid homogeneous precipitation, large specific surface area and Effect of apparent size, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

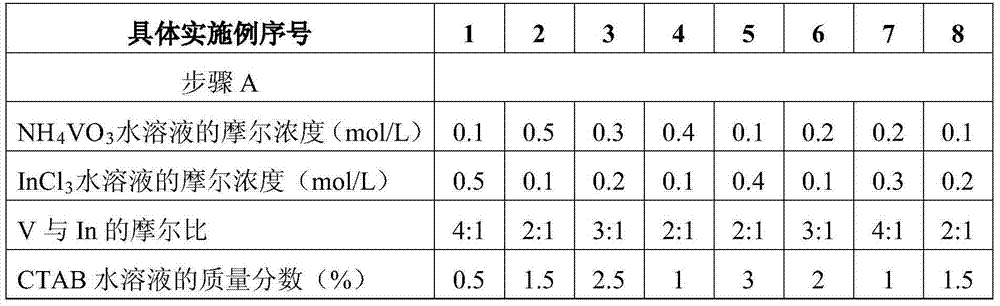

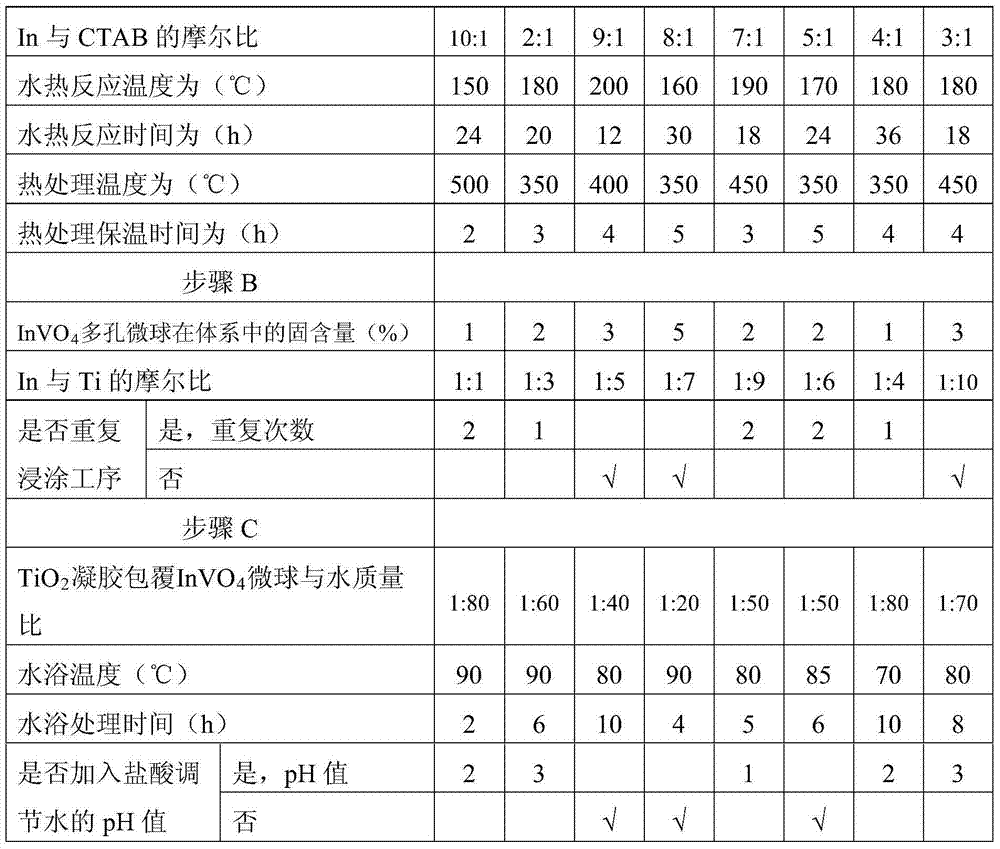

[0020] TiO 2 / InVO 4 The preparation method of composite porous microsphere comprises the following steps:

[0021] Step A: Under stirring conditions, a certain amount of NH 4 VO 3 The aqueous solution was added dropwise with InCl 3 A clear yellow solution was formed in aqueous solution. Use ammonia water to adjust the pH value of the solution system to 4, and obtain a precipitate after stirring for 2 hours; filter and wash the precipitate for 3 times, then add it to an aqueous solution of cetyltrimethylammonium bromide (CTAB), continue stirring for 1 hour, and then transfer to a hydrothermal The reactor was subjected to hydrothermal reaction; after the hydrothermal reaction, the resulting precipitate was filtered, washed three times with distilled water and absolute ethanol, dried at 60°C for 4 hours, and then heat-treated in a muffle furnace to obtain InVO 4 porous microspheres.

[0022] Among them, NH 4 VO 3 The molar concentration of the aqueous solution is 0.1mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com