Preparation method of InVO4/g-C3N4 composite material

A composite material, g-c3n4 technology, applied in the field of preparation of InVO4/g-C3N4 composite materials, to achieve the effect of solving low quantum efficiency, solving poor photoresponse characteristics, and improving high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

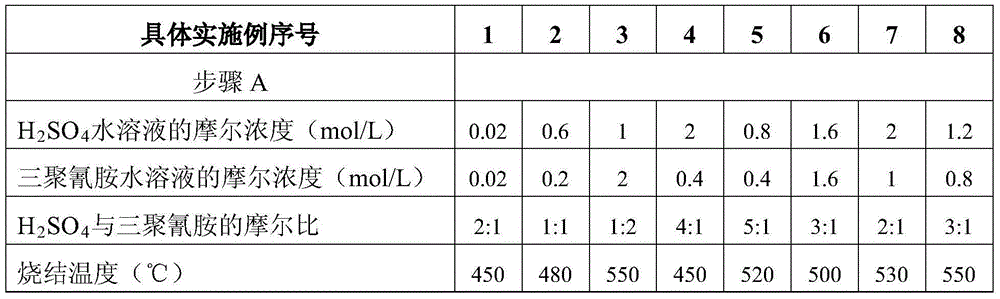

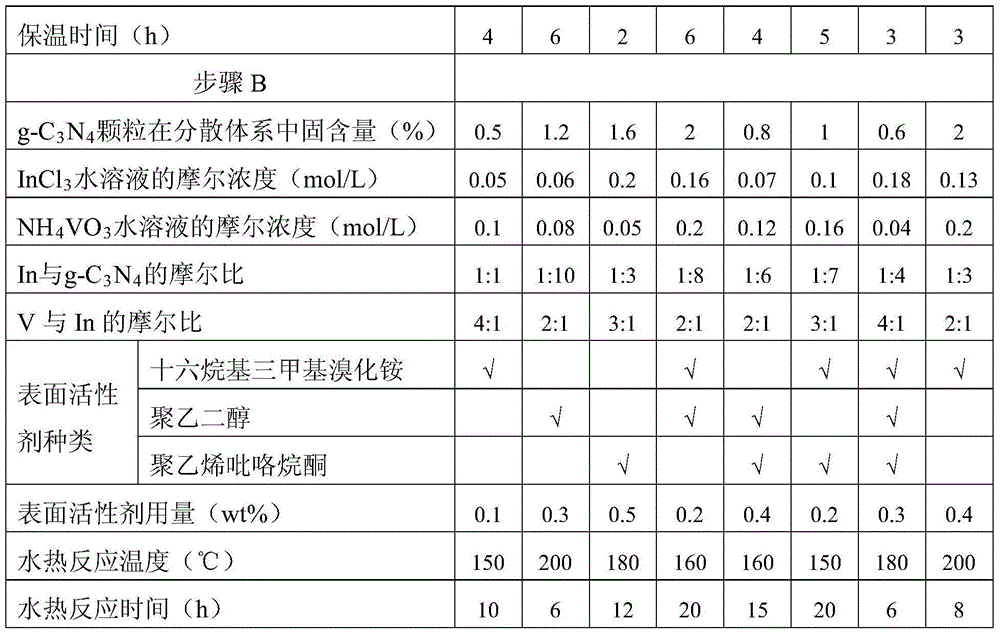

[0018] InVO 4 / g -C 3 N 4 The preparation method of composite material, comprises the following steps:

[0019] Step A: Under stirring conditions, H 2 SO 4 The aqueous solution was added dropwise to the melamine aqueous solution to form a white suspension; the precipitate was obtained after stirring at 80°C for 2 hours; the precipitate was filtered, washed three times with distilled water and absolute ethanol, and dried at 60°C for 24 hours to obtain melamine sulfate; Put it into a corundum boat, and then place it in a tube furnace for sintering. After cooling to room temperature, grind the obtained yellow polymerization product into powder particles to obtain g-C 3 N 4 particles;

[0020] Among them, H 2 SO 4 The molar concentration of aqueous solution is 0.02mol / L~2mol / L, the molar concentration of melamine aqueous solution is 0.02mol / L~2mol / L, the amount of control reactant makes H 2 SO 4 The molar ratio to melamine is 5:1~1:2; the protective atmosphere for sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com