Polycrystalline type for ulipristal acetate and preparation method thereof

A technology of ulipristal acetate and its polymorphism, which is applied in the field of polymorphism of ulipristal acetate, which can solve the problems of difficulty in obtaining high-purity products and helpless removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

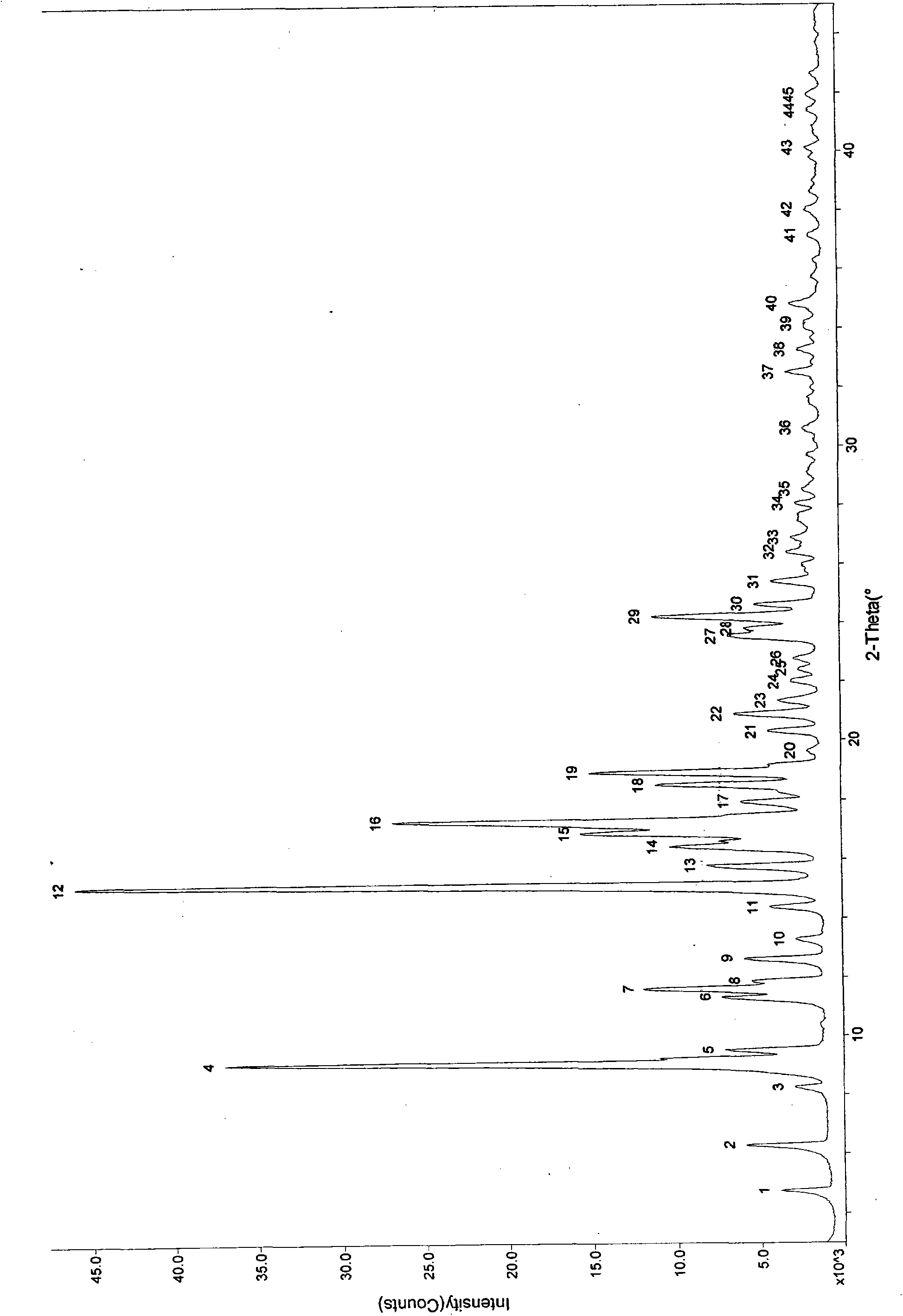

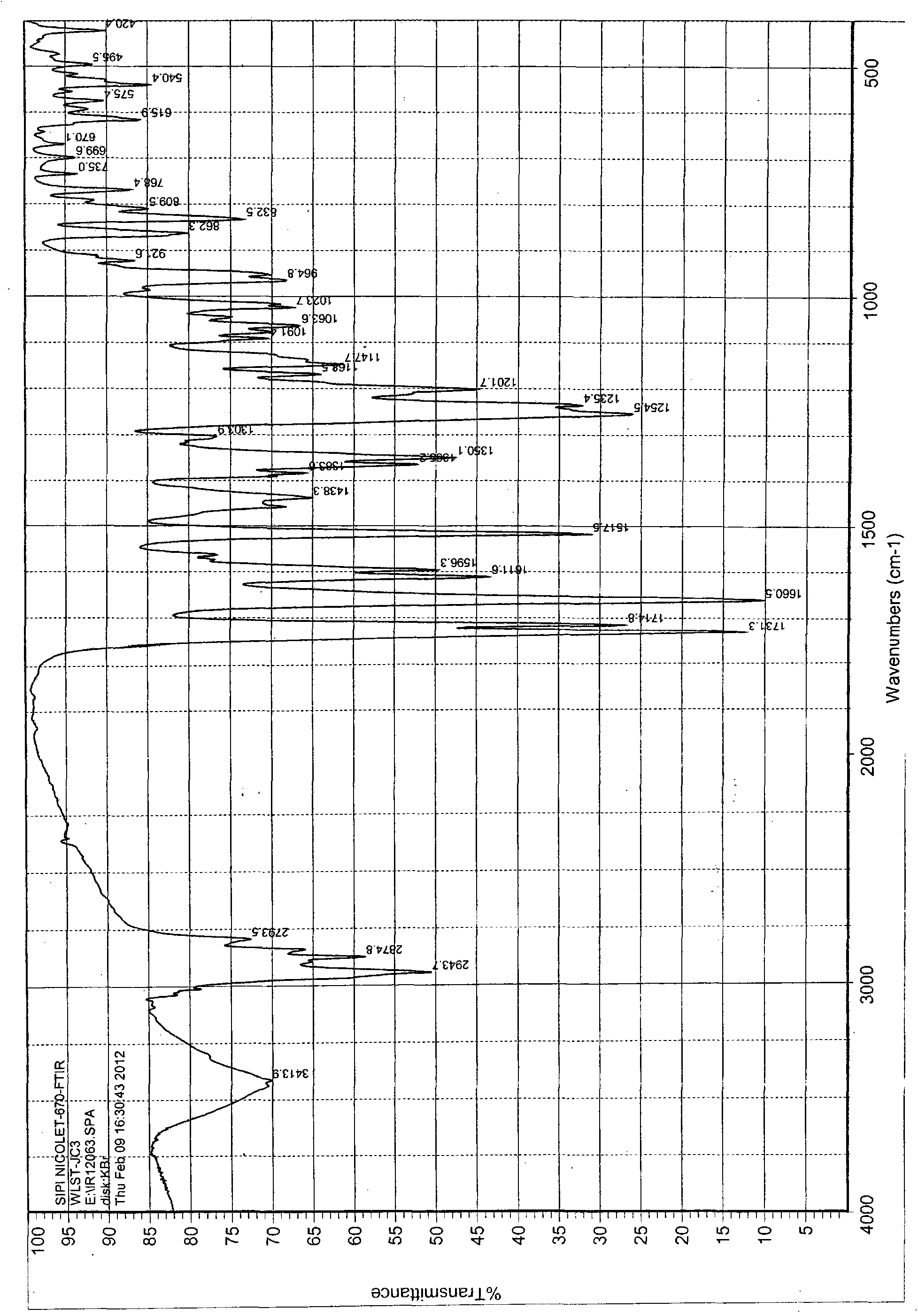

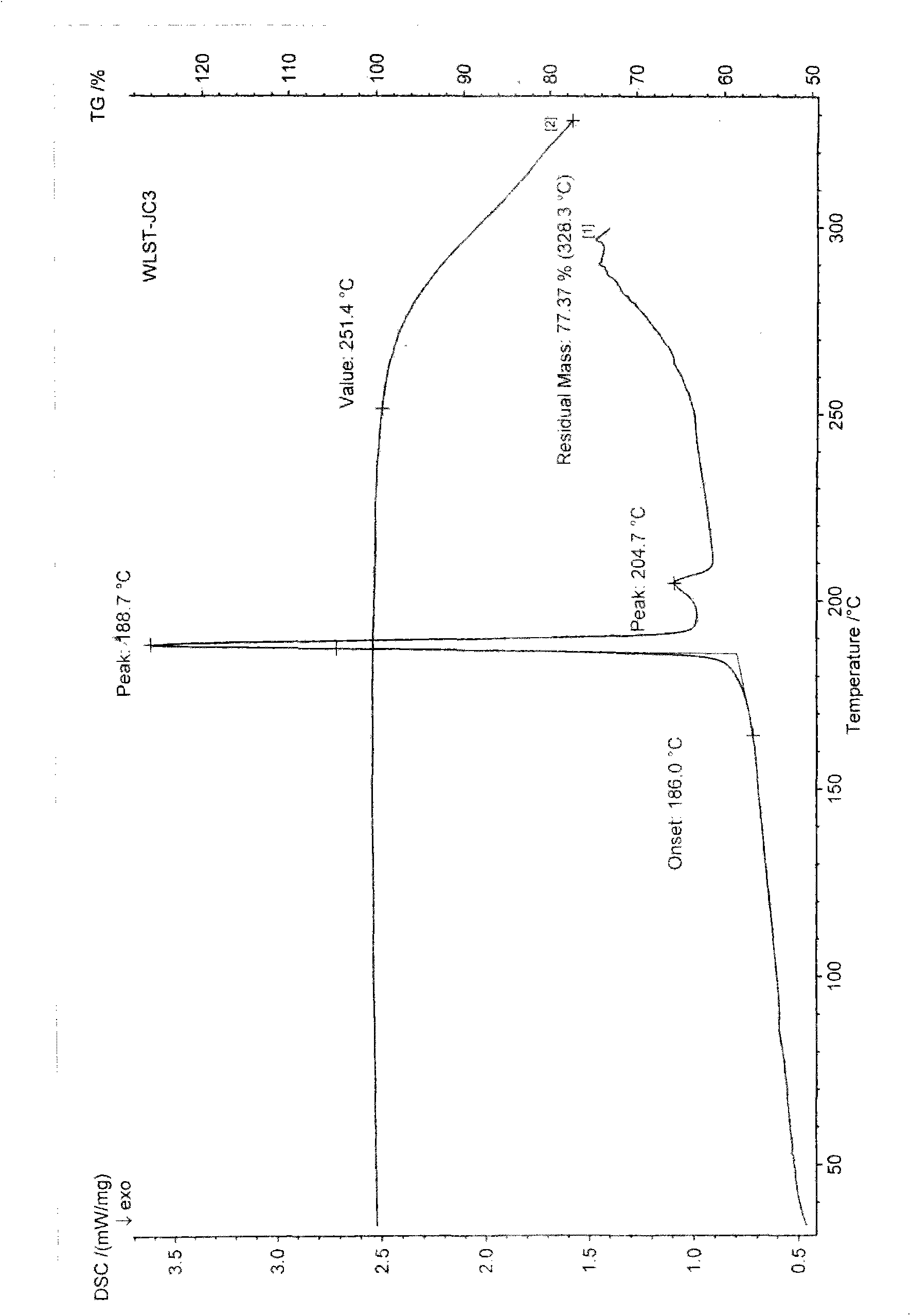

Image

Examples

preparation example 1

[0099] Preparation Example 1: General preparation method of ulipristal acetate solvate polymorph:

[0100] Add 1 g of ulipristal acetate crude product to 10-13 times the volume of ethanol (ml / g), heat to reflux to dissolve, add 0.1 g of activated carbon to decolorize, filter, concentrate under reduced pressure to 3-5 times the volume, and then cool to After stirring at 10°C for 30 minutes to 1 hour, filter. Dry at 60°C. Obtained 0.88 g of ulipristal acetate ethanolate, mp: 150-170°C.

[0101] Also switch to acetone, isopropanol, ethyl acetate, and crystallize to obtain different polymorphs of ulipristal acetate solvate.

preparation example 2

[0102] Preparation Example 2: Preparation method of ulipristal acetate isopropanol / ethanol solvate:

[0103] Add 1 g of crude ulipristal acetate to 10 times isopropanol / ethanol (9:1), heat to reflux to dissolve, add 0.1 g of activated carbon to decolorize, filter, then cool to 10°C while stirring, and stir for 30 minutes to 1 hour ,filter. Dry at 60°C to obtain 0.85 g of ulipristal acetate isopropanol / ethanol solvate, mp: 164-170°C.

preparation example 3

[0104] Preparation Example 3: Ulipristal acetate ethyl acetate / petroleum ether solvate preparation method:

[0105] Add 5 times of dichloromethane to dissolve 1 g of ulipristal acetate crude product, add 0.1 g of activated carbon to decolorize, filter, concentrate under reduced pressure to almost no solvent, add ethyl acetate / petroleum ether (1:5), and cool to 20°C After stirring for 30 minutes-1h, filter. Dry at 60°C to obtain 0.85 g of ulipristal acetate ethyl acetate / petroleum ether solvate, mp: 160-210°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com