Method for removing hydrogen sulfide from raw gas with low hydrogen sulfide content on offshore platform

An offshore platform, hydrogen sulfide technology, applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems of long regeneration time, low efficiency, huge sulfur separation equipment, etc., achieve high desulfurization degree, high efficiency, and save the regeneration part Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

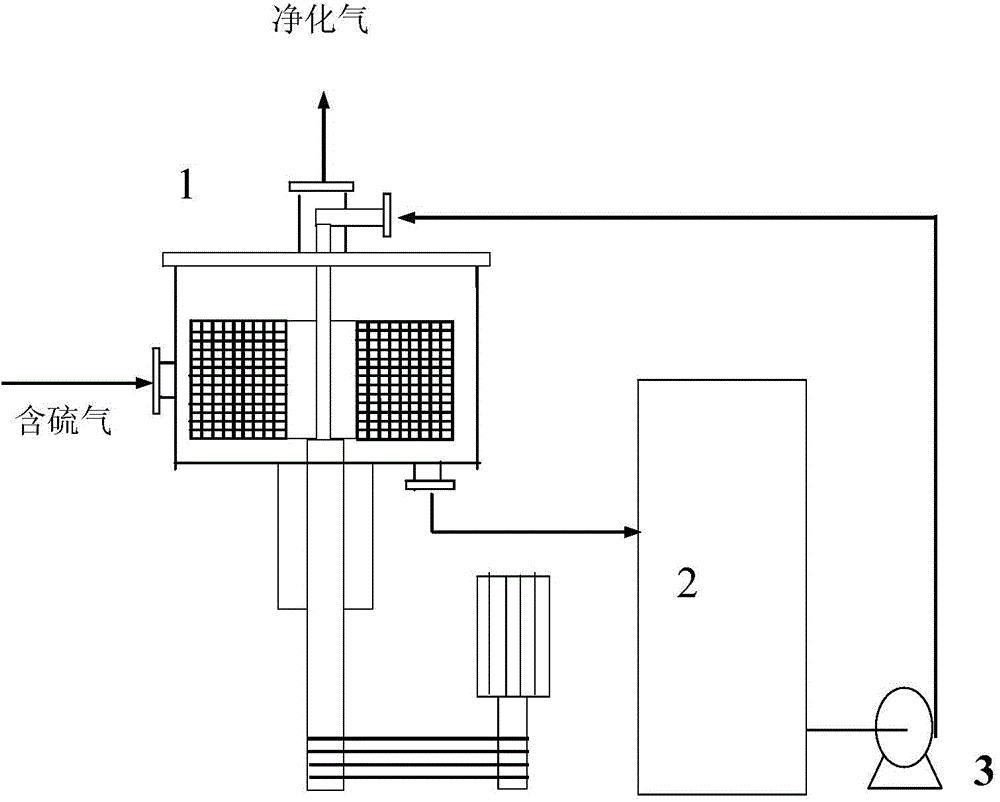

Image

Examples

Embodiment 1

[0022] For the removal of low-concentration hydrogen sulfide in natural gas, a supergravity machine with a diameter of 0.6m and a height of 1.8m is used, with a rotation speed of 500rpm, and the filler is stainless steel embossed mesh filler; the offshore platform natural gas H 2 S concentration 30ppm, gas volume 12.4m 3 / h, pressure 6.8MPa, flow rate of desulfurization agent 1m 3 / h, pH=9.6, desulfurization temperature 30°C, after the system is stable, the measured outlet concentration is 0ppm (undetectable).

Embodiment 2

[0024] As described in Example 1, other conditions remain unchanged, and the natural gas volume is adjusted to 75m 3 / h, the measured outlet concentration is 0ppm (undetectable).

Embodiment 3

[0026] As described in Example 1, other conditions remain unchanged, and the amount of desulfurization agent solution is adjusted to 0.5m 3 / h, the measured outlet concentration is 0ppm (undetectable).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com