Vacuum electric annealing furnace

An annealing furnace and vacuum technology, applied in the field of mold steel manufacturing equipment, can solve problems such as increased production costs, expensive oil, unsuitable control of combustion temperature, etc., and achieve the effects of improving sealing and heat preservation performance, reducing heat loss, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

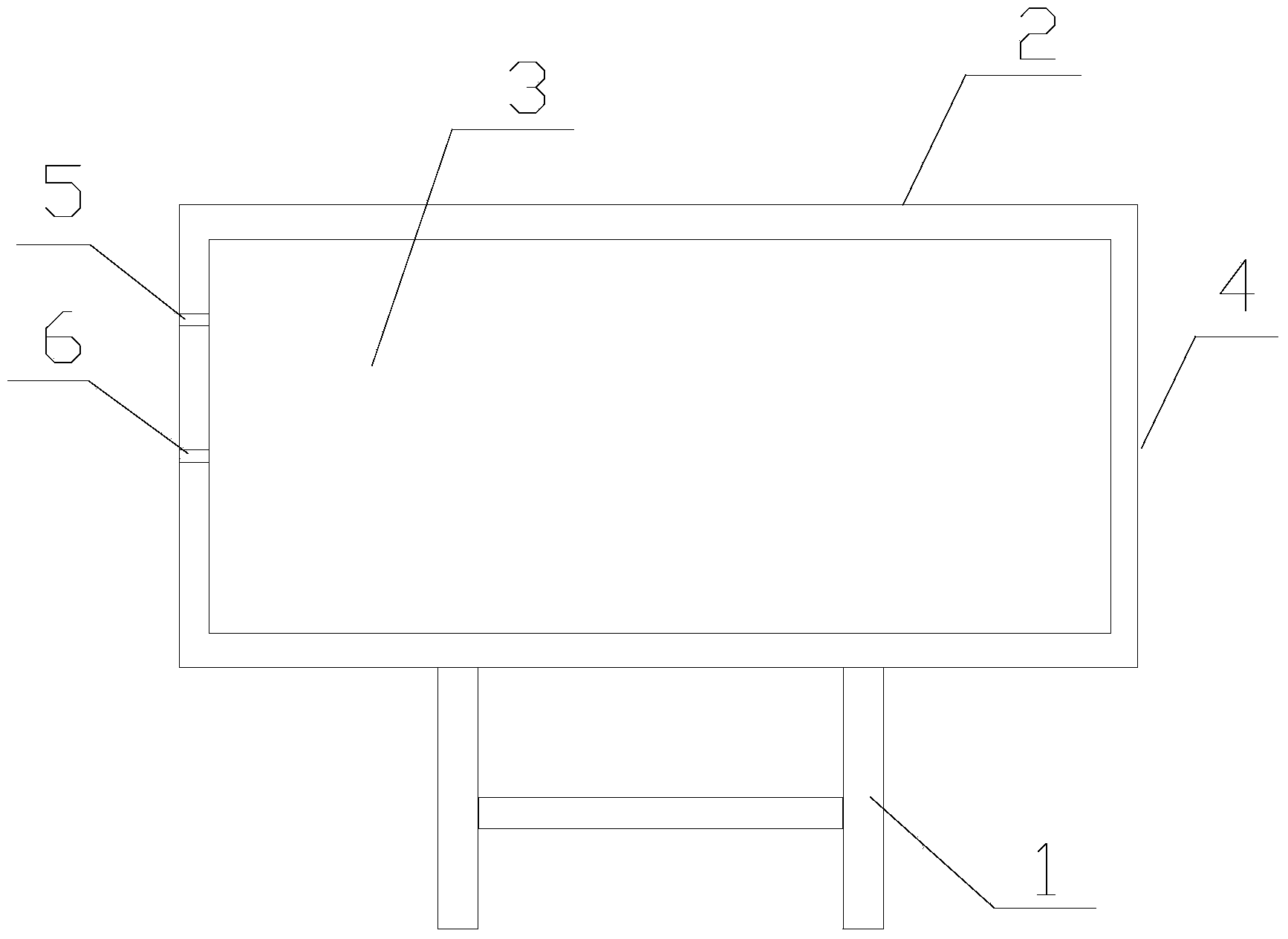

[0013] Example 1: Such as figure 1 As shown, a vacuum electric annealing furnace includes a frame 1, a furnace body 2 and an annealing chamber 3 arranged in the furnace body, the two ends of the furnace body are open, and a conveying device is arranged therein, and the two ends of the furnace body The opening is provided with an airtight furnace cover 4, and the furnace cover is provided with a vacuuming pipeline 5 and a nitrogen filling pipeline 6, and the described vacuuming pipeline 5 and the nitrogen charging pipeline 6 are distributed and connected with a vacuuming device and a nitrogen filling device, so The annealing chamber 3 is provided with an inner lining of aluminum silicate fiber cotton, and ring-shaped bricks are evenly embedded on the inner lining along its length direction, and resistance wires are installed on the bricks.

[0014] The furnace cover is made of 30mm thick steel plate, and the inner side of the furnace cover is provided with an insulating layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com