Residual heat utilizing pusher furnace

A push rod type, waste heat technology, used in heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of large furnace body, low energy utilization rate, harsh operating environment, etc., to reduce the floor space and effect. Ideal, shortened length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

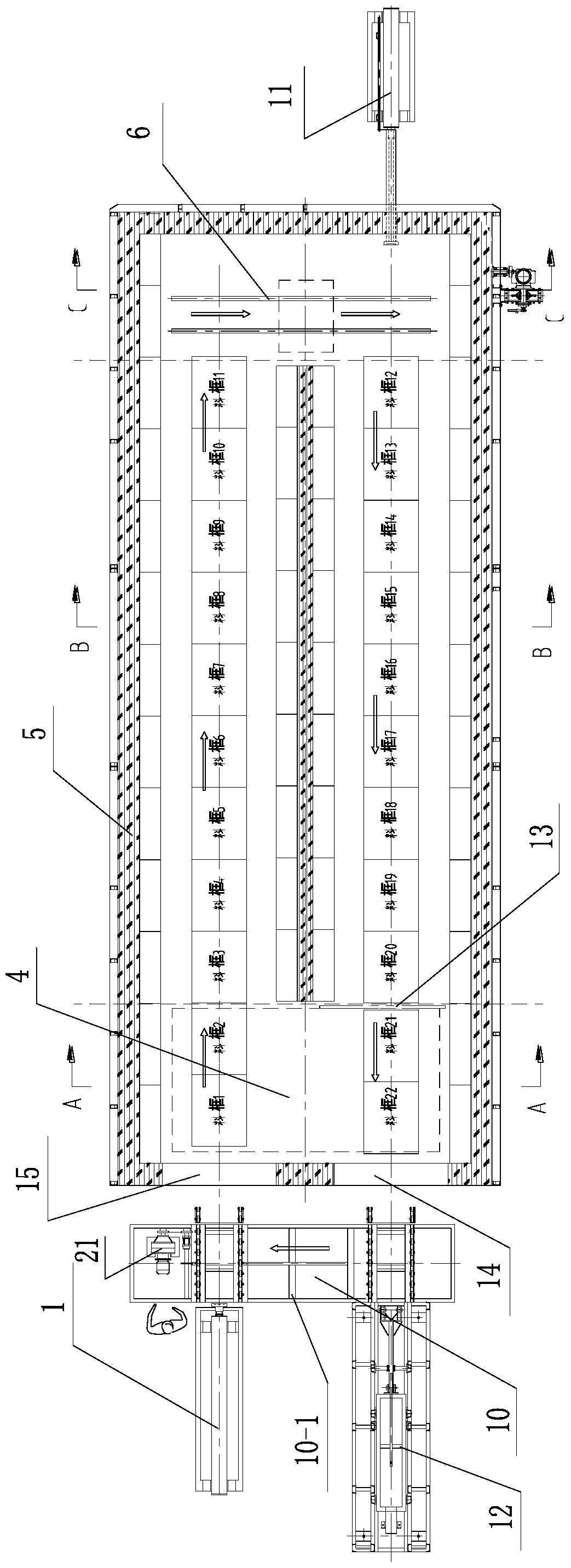

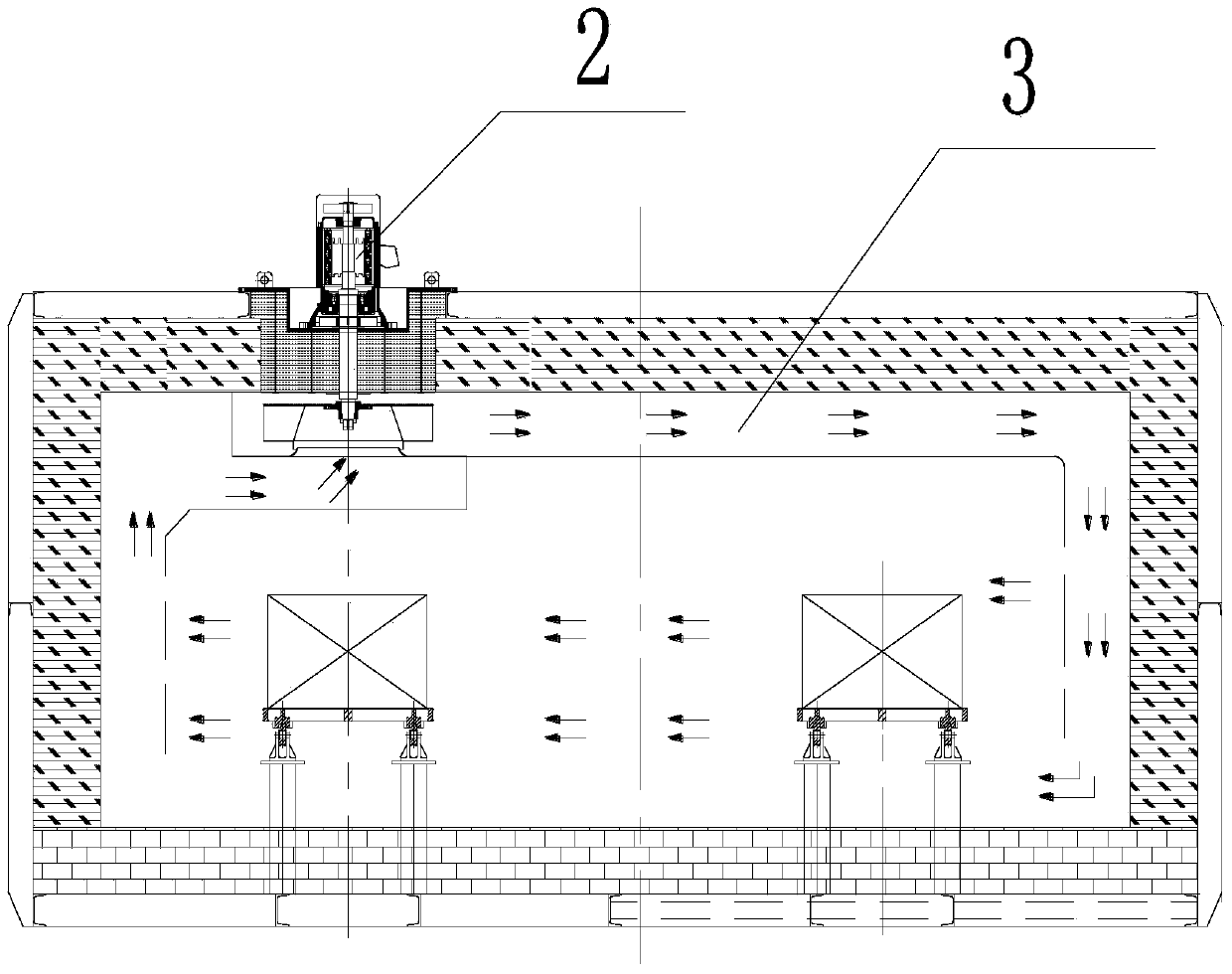

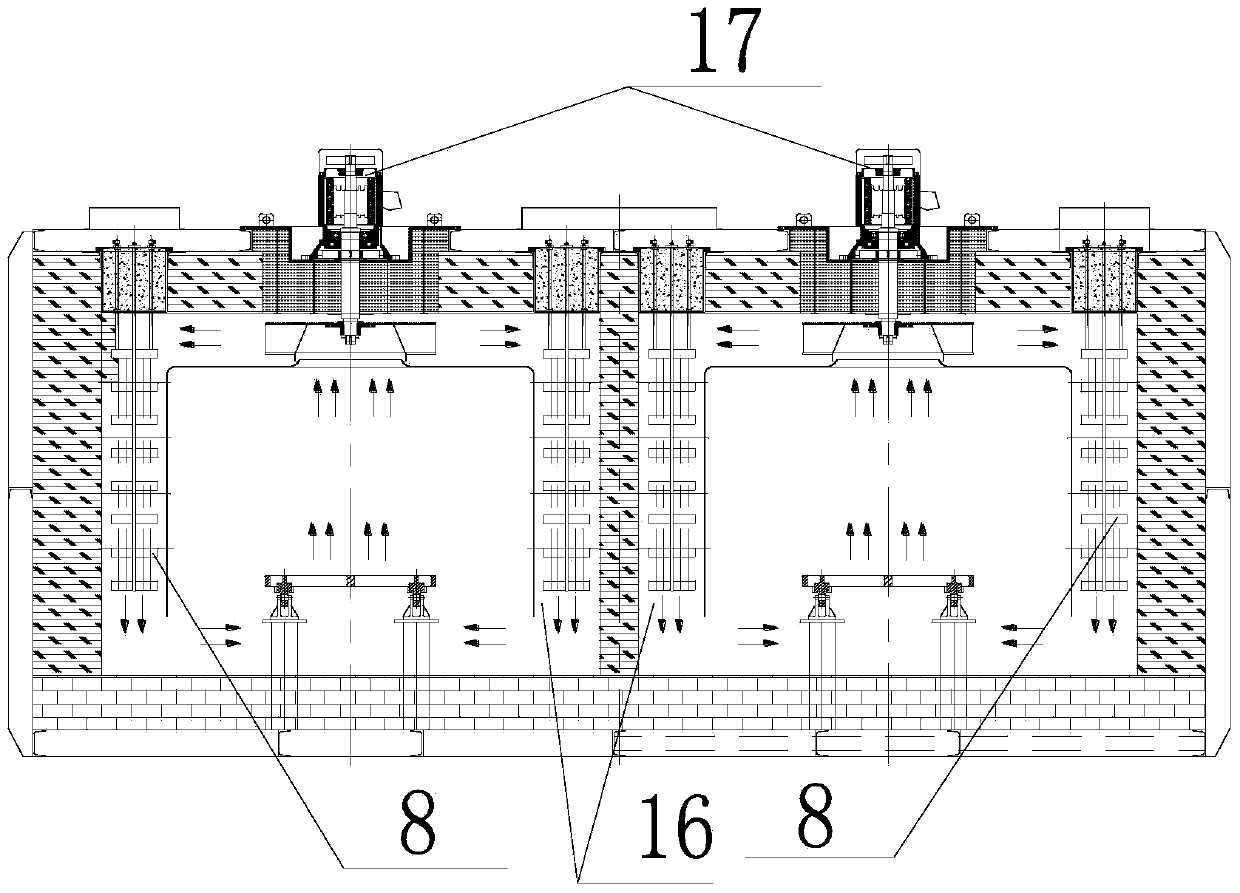

[0019] Such as Figure 1 to Figure 4 The shown push rod furnace with waste heat utilization includes a furnace body 5, the front end of the furnace body 5 is provided with a feed door 15 and a discharge door 14, and the front of the furnace body 5 is provided with an external translation device 10, and the furnace body 5 A preheating cooling chamber 4 is arranged in the front part, two parallel material passages are arranged in the middle along the direction of the length of the furnace body 5, and a translation passage in the furnace is arranged in the tail, and the preheating cooling chamber 4 and the translation passage in the furnace are respectively connected to two The front end and the rear end of the material passage, the conveying rollers are arranged in the preheating cooling chamber 4 and the material passage, the translation mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com