A kind of growth method of gan nanowire

A growth method and nanowire technology, which is applied to the growth of GaN nanowires and the field of growing GaN nanowires, can solve the problems of high price, difficulty in preparing large-size sapphire substrates, and high price, and achieve the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

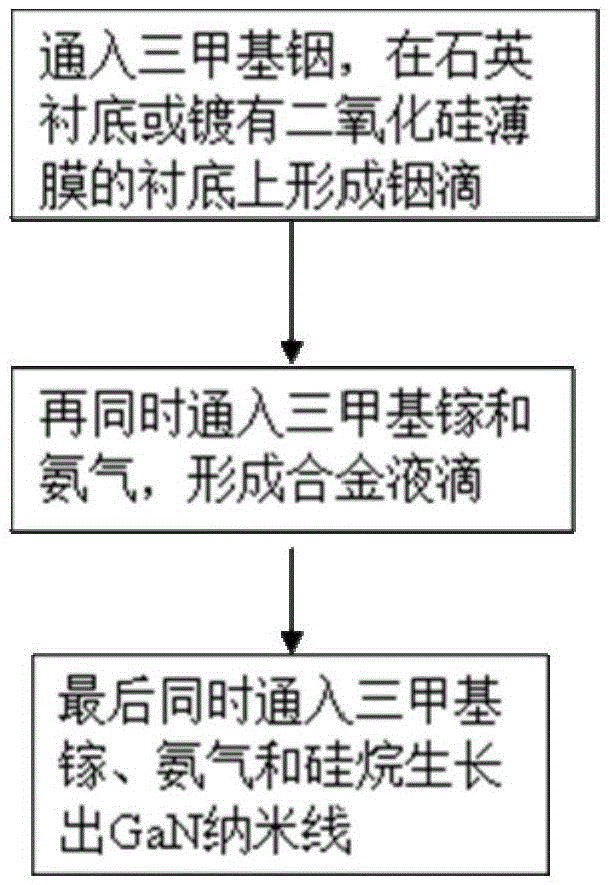

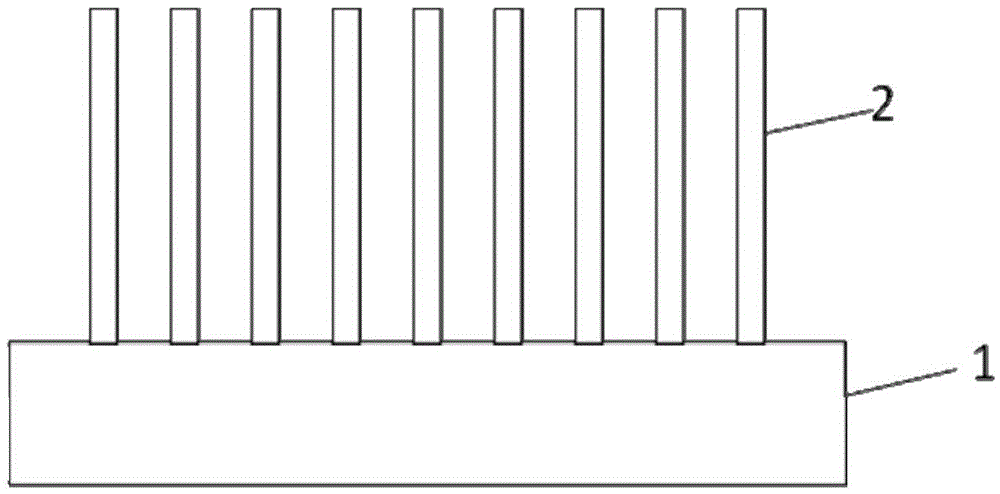

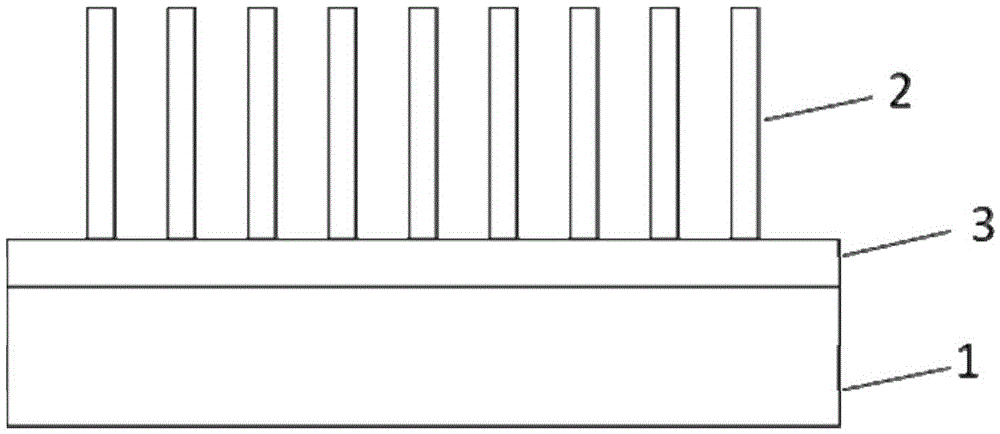

[0037] Sample pattern diagram of GaN nanowires grown on quartz substrate figure 2 As shown, from bottom to top are, quartz substrate, GaN nanowire; its preparation method is:

[0038] 1) Put the quartz substrate into the MOCVD reaction chamber, and heat-treat the substrate at 1000°C for 15 minutes in a hydrogen atmosphere;

[0039] 2) At 700°C, with a bias voltage of 400mbar, trimethylindium (TMIn) was injected for 30s, and liquid indium droplets were formed on the substrate with a density of about 8×10 6 piece / cm 2 ;

[0040] 3) Then feed ammonia gas and trimethylgallium (TMGa) at the same time, the molar flow rate of trimethylgallium is 60 μmol / min, the molar flow rate of ammonia gas is 50 times that of trimethylgallium, and GaN is formed and dissolved in indium droplets , forming alloy droplets with a droplet diameter of 100-300nm;

[0041] 4) Finally, ammonia gas, trimethylgallium (TMGa) and silane are introduced at the same time. The flow rate of ammonia gas and trim...

Embodiment 2

[0043] Sample pattern diagram of GaN nanowires grown on quartz substrate figure 2 As shown, from bottom to top are, quartz substrate, GaN nanowire; its preparation method is:

[0044] 1) Put the quartz substrate into the MOCVD reaction chamber, and heat-treat the substrate at 1000°C for 20 minutes in a hydrogen atmosphere;

[0045] 2) At 600°C, with a bias voltage of 350mbar, trimethylindium (TMIn) was pre-introduced for 150s to form liquid-phase indium droplets on the substrate with a density of about 6×10 7 piece / cm 2 ;

[0046] 3) Then feed ammonia gas and trimethylgallium (TMGa) at the same time, the molar flow rate of trimethylgallium is 60 μmol / min, and the molar flow rate of ammonia gas is 100 times that of trimethylgallium, so that GaN is formed and dissolved in indium drops, forming alloy droplets with a diameter of 100-300nm;

[0047] 4) Finally, ammonia gas, trimethylgallium (TMGa) and silane are introduced at the same time. The flow rate of ammonia gas and tri...

Embodiment 3

[0049] Sample pattern diagram of GaN nanowires grown on quartz substrate figure 2 As shown, from bottom to top are quartz substrate and GaN nanowire. Its preparation method is:

[0050]1) Put the quartz substrate into the MOCVD reaction chamber, and heat-treat the substrate at 1100°C for 20 minutes in a hydrogen atmosphere;

[0051] 2) At 600°C, with a bias voltage of 450mbar, trimethylindium (TMIn) was introduced for 300s to form liquid indium droplets on the substrate with a density of about 5×10 8 piece / cm 2 ;

[0052] 3) Then feed ammonia gas and trimethylgallium (TMGa) at the same time, the molar flow rate of trimethylgallium is 80 μmol / min, and the molar flow rate of ammonia gas is 10 times that of trimethylgallium, so that GaN is formed and dissolved in indium drops, forming alloy droplets with a diameter of 400-500nm;

[0053] 4) Finally, ammonia gas, trimethylgallium (TMGa) and silane are introduced at the same time. The flow rate of ammonia gas and trimethylgal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com