Fourdrinier shaking and vibrating device of fourdrinier papermaking machine

A technology for a fourdrinier wire paper machine and a wire section is applied in the field of papermaking machinery to achieve the effects of reducing fiber flocculation, improving sheet formation, and reducing equipment failure rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

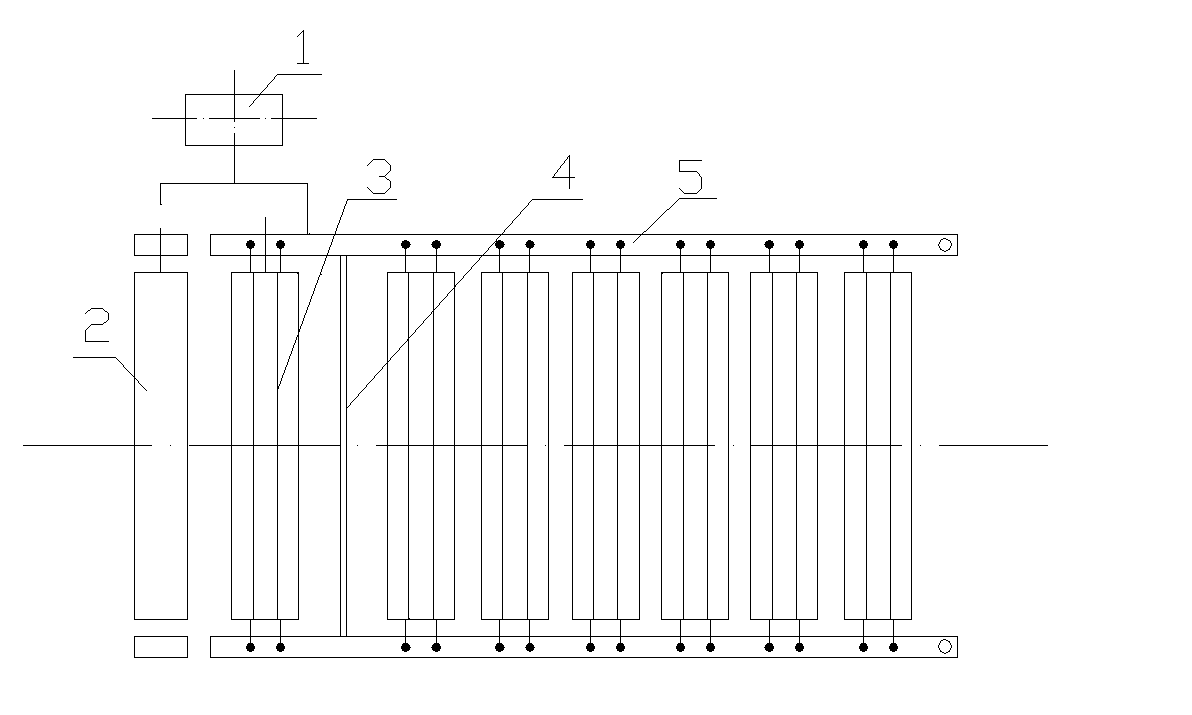

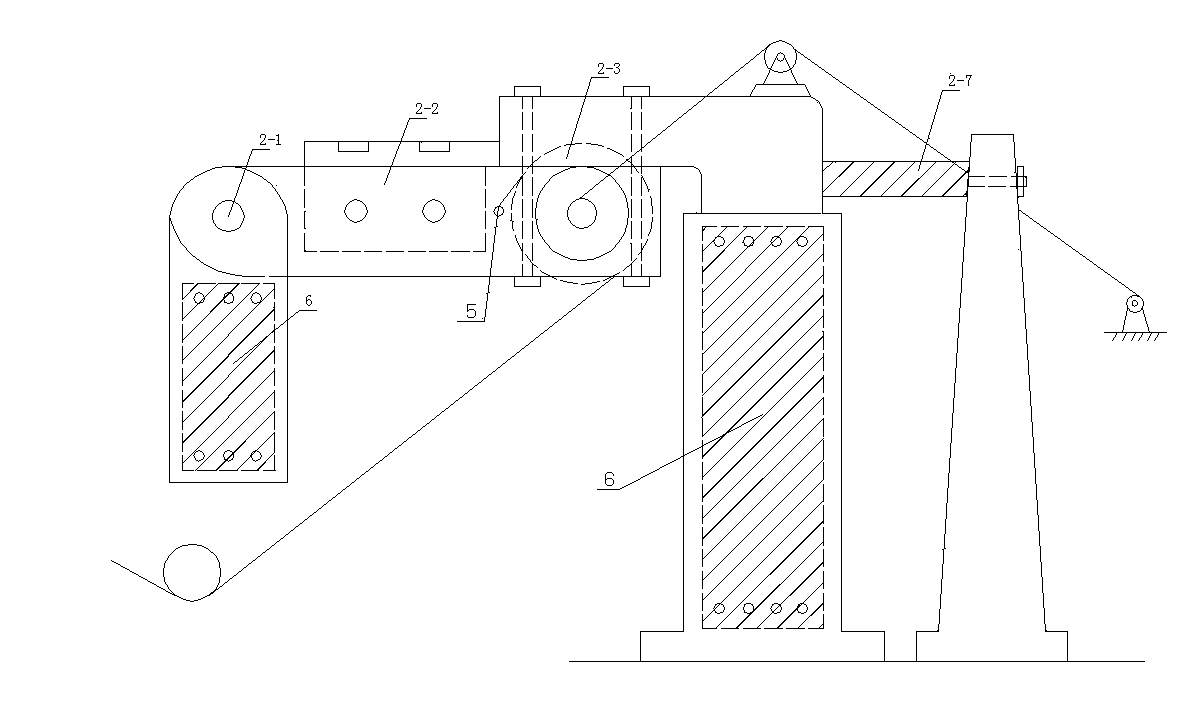

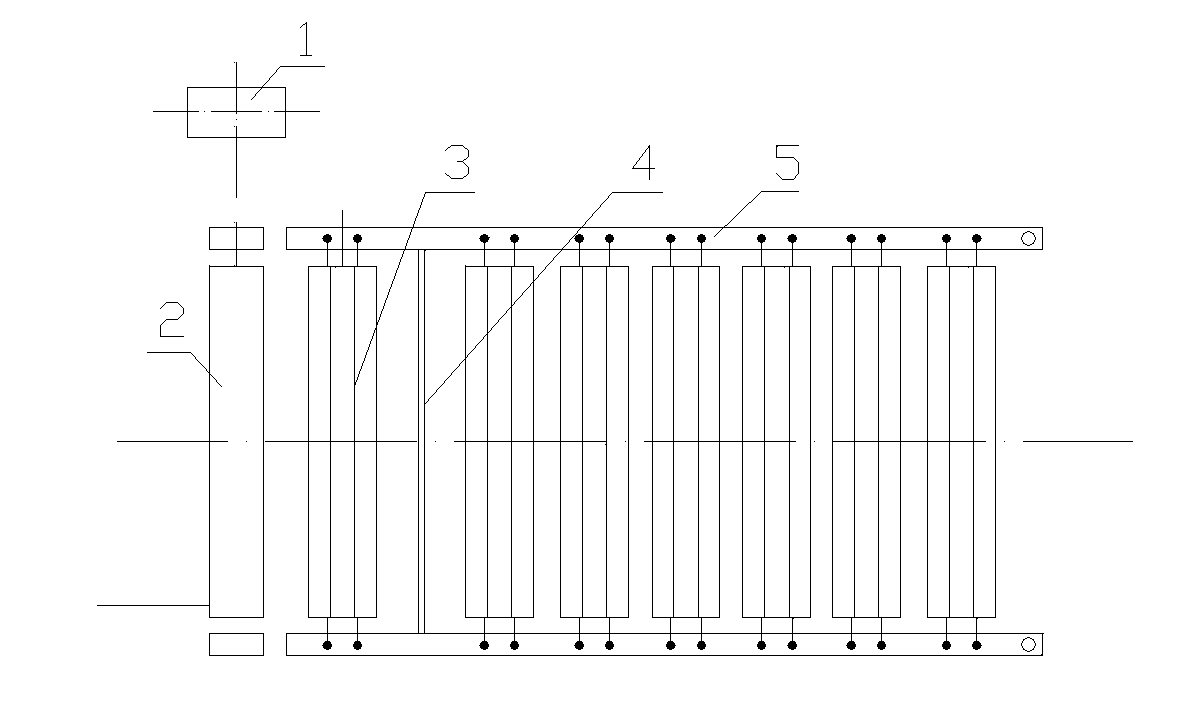

[0019] The shaking device of the wire part of the fourdrinier paper machine of the present invention is an improvement on the basis of the existing shaking device of the wire part of the fourdrinier paper machine. The existing fourdrinier paper machine wire shaking device such as figure 1 and figure 2 As shown, including breast roll 2 and breast roll bearing housing 2-3, chopping board 3, connecting beam 4 and longitudinal beam 5, breast rolling bearing housing 2-3, chopping board 3 and connecting beam 4 are all installed on the longitudinal beam 5, by Shaking speed governor 1 drives breast roller 2, chopping board 3 etc. to do reciprocating motion together. The improvement of the present invention is: disconnect the breast roll bearing seat from the original connecting longitudinal beam 4 (bolt connection holes should be left on the sides of the longitudinal beam and the bearing seat, after the bearing seat and the longitudinal beam are fixed when replacing the forming net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com