Pre-tensioning-mode centrifugal concrete pile with steel strands and manufacturing method

A technology of concrete piles and steel strands, applied in the field of pile foundation engineering, can solve problems such as difficult end plates or tension plates, anchor plates are firmly fixed, pile body prestressed damage, easy to be broken, etc., to achieve a locking method Simple and reasonable, consistent tensile strength and greatly improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

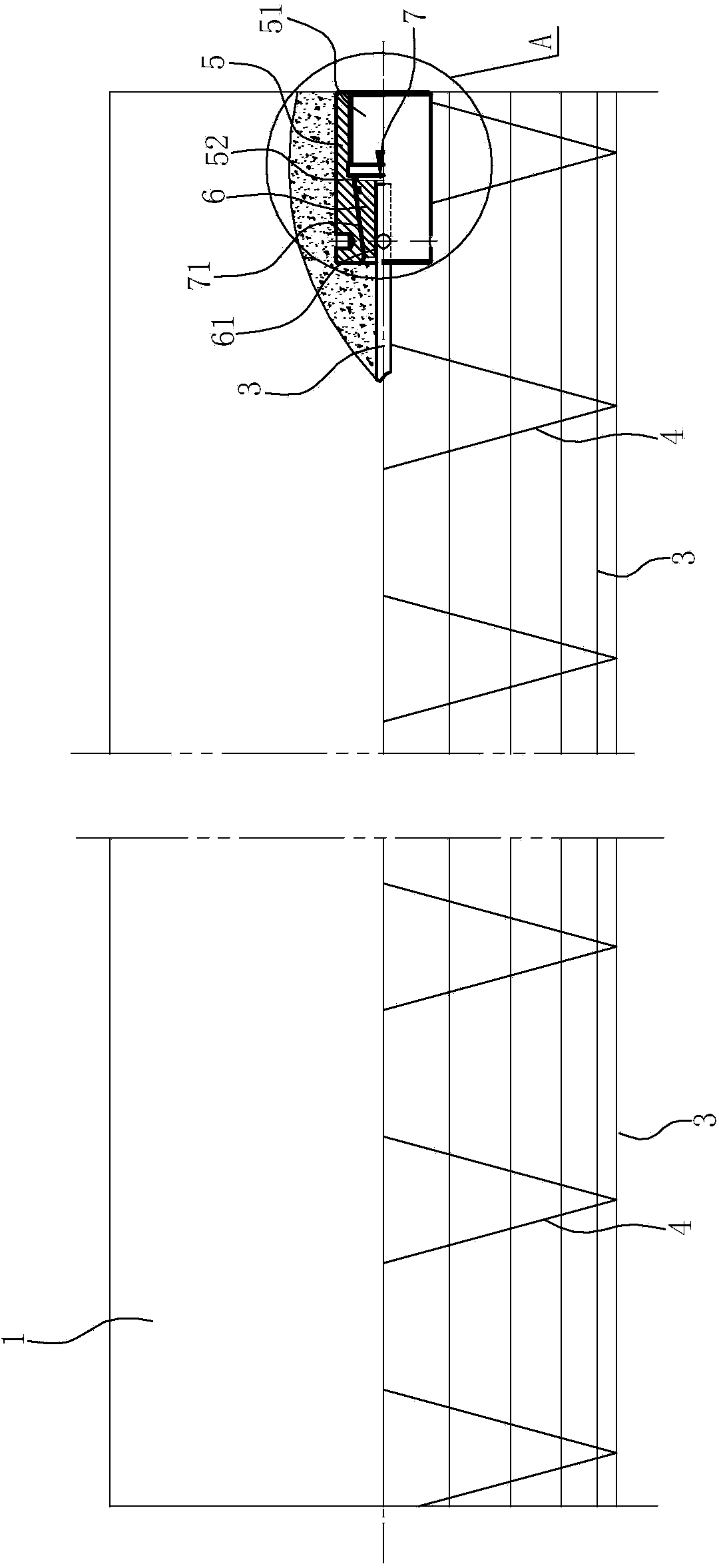

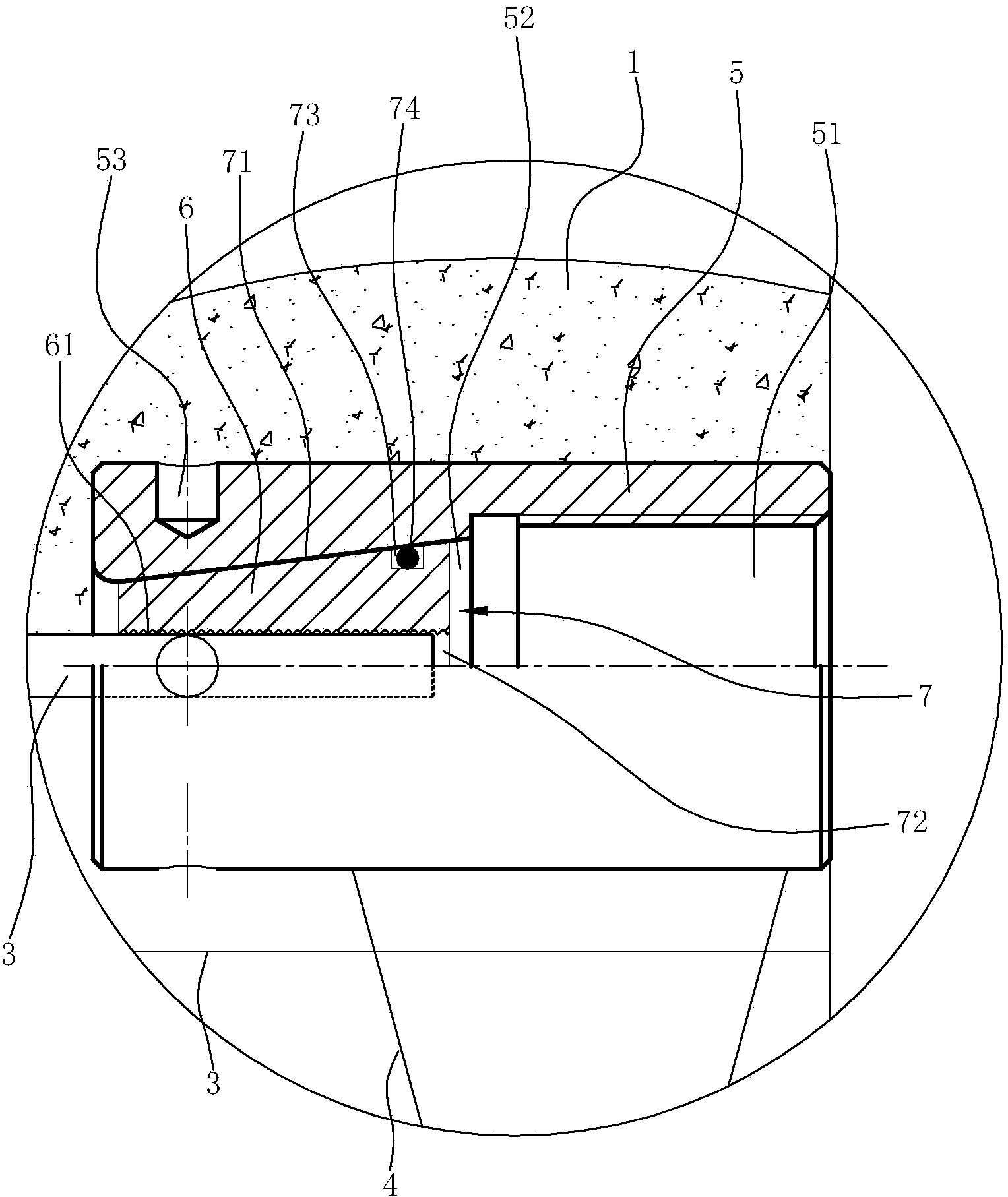

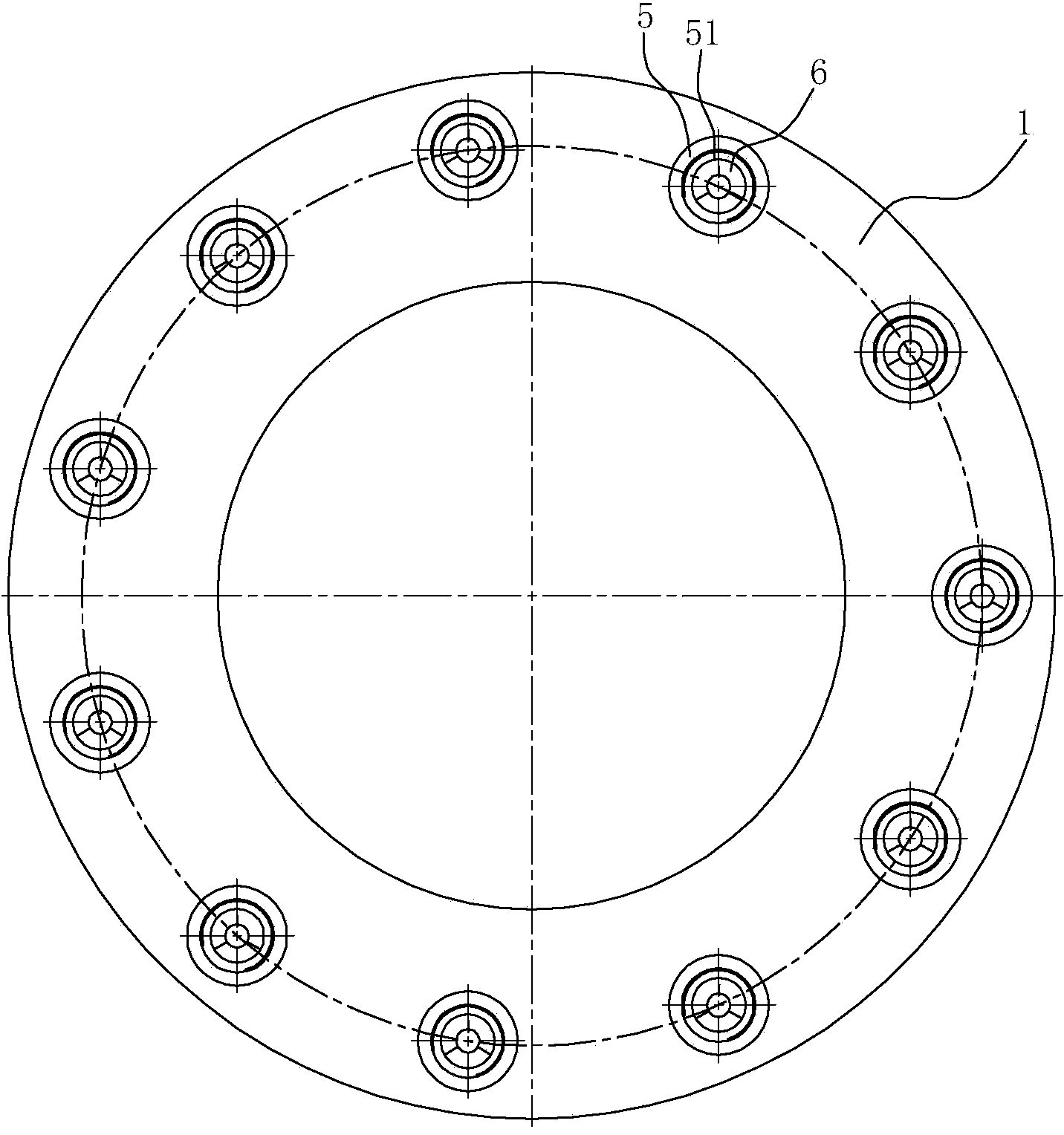

[0045] like Figures 1 to 10 shown, is the preferred embodiment of the present invention.

[0046] A pretensioned centrifugal concrete pile with steel strands, comprising a hollow concrete pile body 1, an end plate 2 and a reinforcing cage located in the concrete pile body 1, and the concrete pile body 1 can be a circular pile or a square shape. For piles, polygonal piles and various pre-tensioned prestressed centrifugal concrete shaped piles, two end plates 2 are connected to the end faces of both ends of the concrete pile body 1 . The reinforcement cage includes the axially arranged prestressed main reinforcement and the stirrups 4 wound around the main reinforcement. The prestressed main reinforcement is the steel strand 3. The fixation between the stirrup 4 and the steel strand 3 can be done by hand binding or by using The concrete pile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com