Heat recovery variable-frequency multi-split heat pump system and control method thereof

A heat pump system and heat recovery technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high cost, complicated system piping and control, etc., to improve thermal comfort, increase cooling capacity and heating capacity , the effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

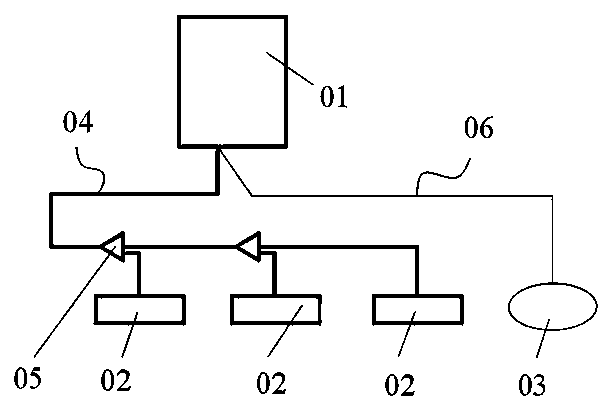

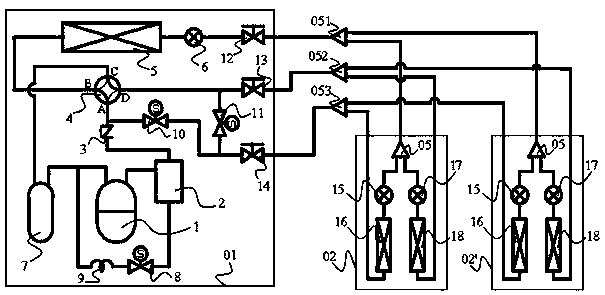

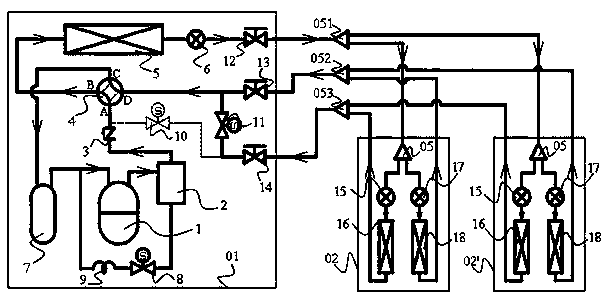

[0032] In this embodiment, two indoor units are taken as examples to specifically describe the implementation of the present invention:

[0033] Such as figure 2 As shown, the multi-connected heat pump system of this embodiment is composed of an outdoor unit 01 and two indoor units 02, 02'. Outdoor unit 01 includes: compressor 1, oil separator 2, one-way valve 3, four-way valve 4, outdoor heat exchanger 5, outdoor electronic expansion valve 6, gas-liquid separator 7, first solenoid valve 8, capillary tube 9 , the second solenoid valve 10, the third solenoid valve 11, the liquid side stop valve 12, the gas side stop valve 13 and the exhaust stop valve 14.

[0034]The first indoor unit 02 includes: a first indoor electronic expansion valve 15 , a first indoor heat exchanger 16 , a second indoor electronic expansion valve 17 , a second indoor heat exchanger 18 and a fourth branch pipe 05 . The components and configuration of the second indoor unit 02' are the same as those of ...

specific Embodiment 2

[0058] The multi-connected heat pump system of this embodiment is composed of an outdoor unit 01 and three indoor units 02, 02′, 02″. The outdoor unit includes two parallel inverter compressors. The pipelines of the indoor unit 02″ pass through branch pipes respectively 051', 052', 053' are connected to the pipeline of indoor unit 02'. The rest of the structures and implementation conditions are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com