Wafer-level packaging structure, forming method thereof, and packaging method

A technology of wafer-level packaging and packaging methods, which is applied in the direction of radiation control devices, etc., can solve problems such as grain damage and adverse effects on image sensor performance, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It can be seen from the background technology that after the image sensor is packaged in the prior art, it is necessary to peel off the package cover from the die. How to separate the package cover from the die without damaging the die is an urgent problem to be solved at present. .

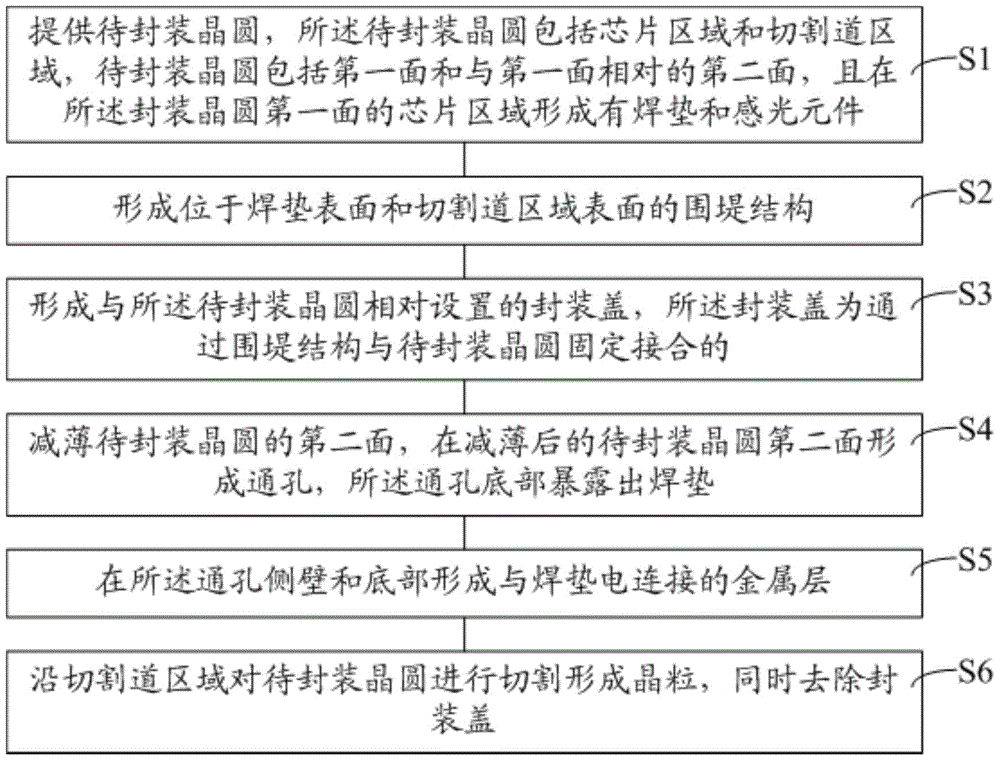

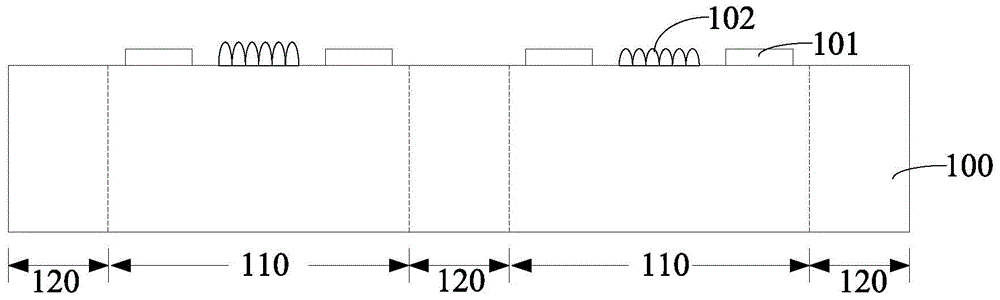

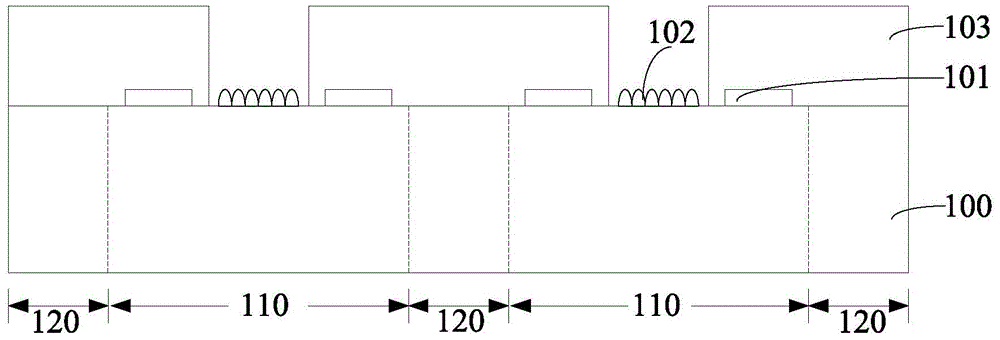

[0040] In order to solve the above problems, the wafer-level packaging structure and packaging method of image sensors are studied, and a packaging method including the following steps is proposed: Step S1, providing a wafer to be packaged, the wafer to be packaged includes a chip area and a dicing line area , the wafer to be packaged includes a first surface and a second surface opposite to the first surface, and a bonding pad and a photosensitive element are formed on the chip area of the first surface of the packaging wafer; step S2, forming a Dike structure on the surface of the dicing line area; step S3, forming a packaging cover opposite to the wafer to be packaged, the packaging c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com