Torque output control system of permanent magnet synchronous motor

A permanent magnet synchronous motor and control system technology, applied in the control system, vector control system, motor generator control and other directions, can solve the problem of motor inductance motor output torque control deviation, etc., to solve the problem of torque accuracy, avoid complex processes, To achieve convenient and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

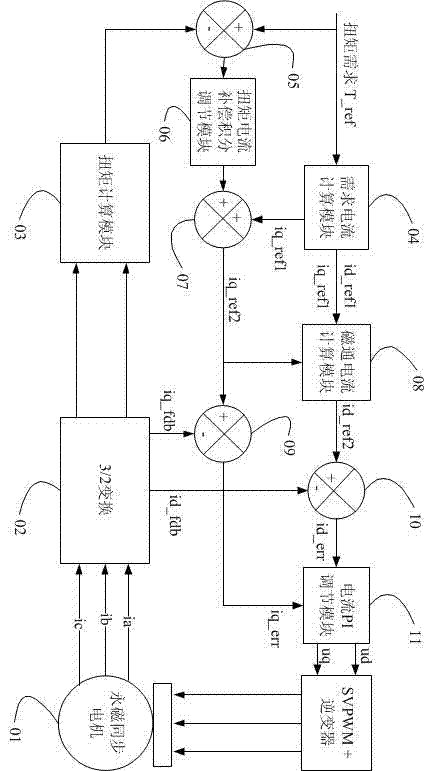

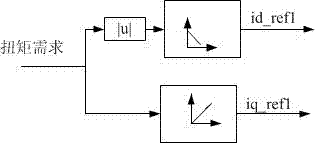

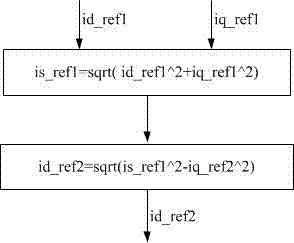

[0070] Such as figure 1 As shown, the permanent magnet synchronous motor torque output control system of the embodiment of the present invention includes a SVPWM modulation module, an inverter, a permanent magnet synchronous motor 01, a 3 / 2 change module 02, a torque calculation module 03, a demand current calculation module 04, Torque comparator 05 , torque current compensation integral adjustment module 06 , torque current adder 07 , magnetic flux current calculation module 08 , torque current comparator 09 , magnetic flux current comparator 10 and current PI adjustment module 11 .

[0071] The modulation module, the inverter and the permanent magnet synchronous motor 01 are electrically connected in sequence, and the three-phase output of the permanent magnet synchronous motor 01 is respectively connected to the 3 / 2 conversion module 02 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com