Separable membrane improvements

A kind of porous membrane, a part of the technology, applied in the field of droplet production equipment, can solve the problem of easy attenuation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

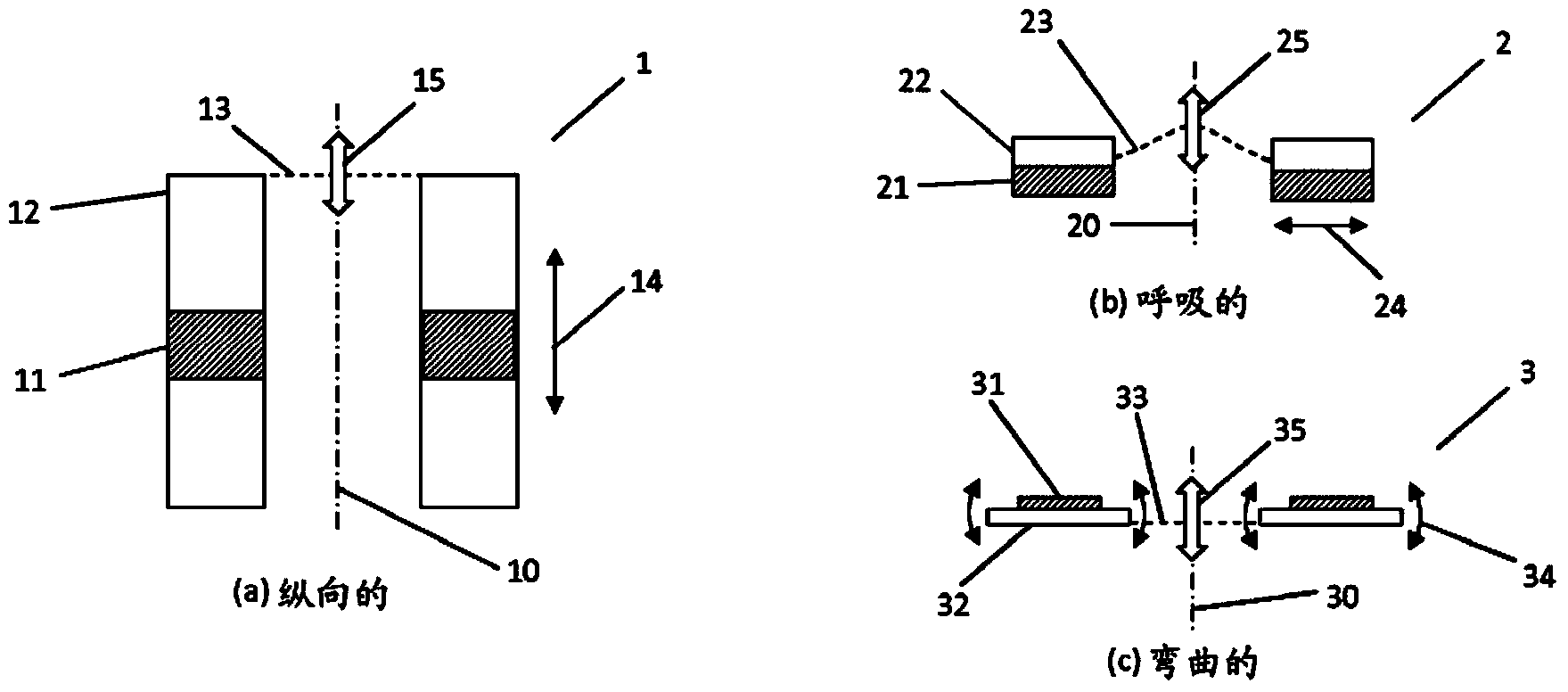

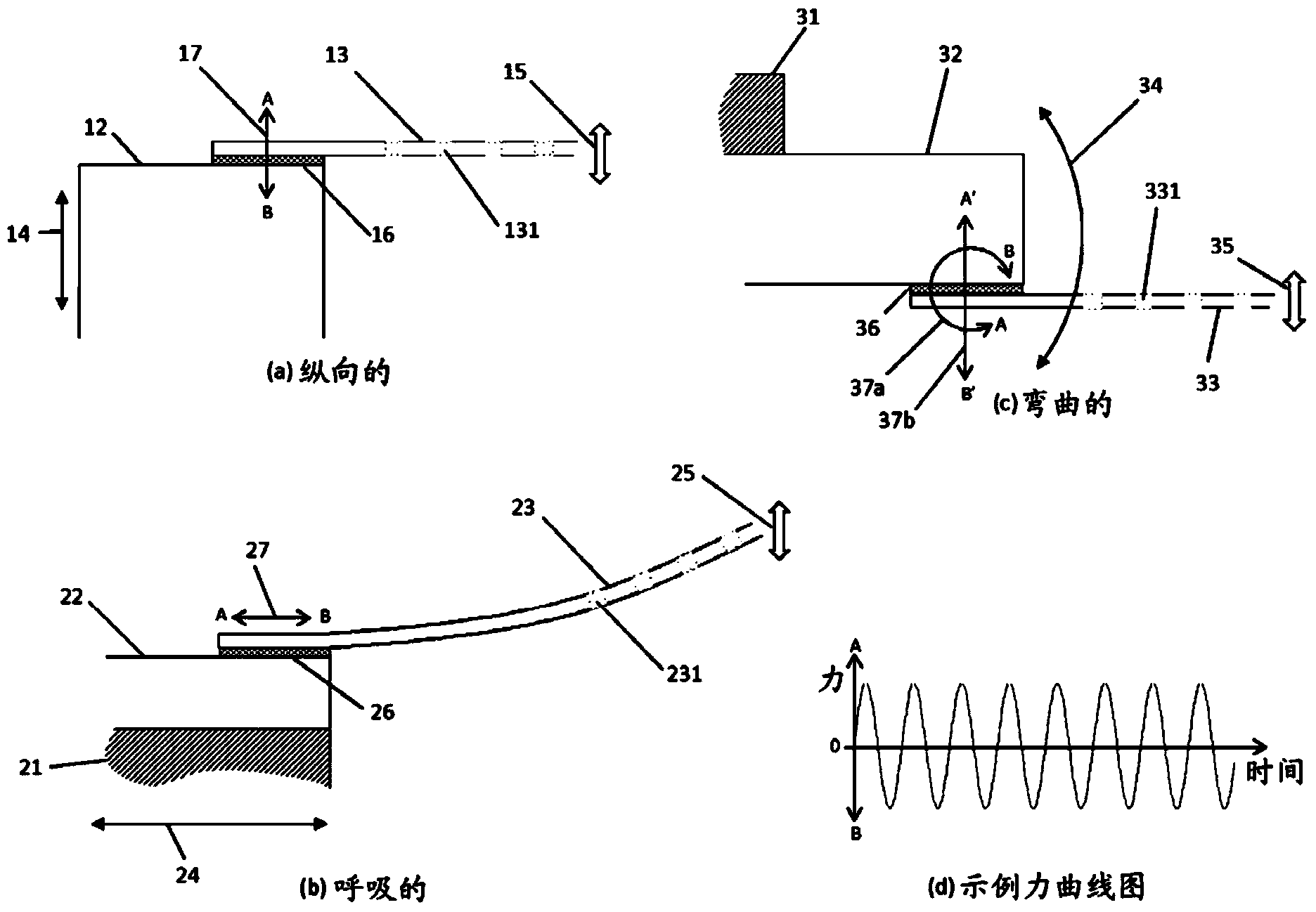

[0040] figure 1 (a) shows an axisymmetric droplet production device known in the art of longitudinal type 1 . The actuator comprises an active component 11 combined with a deformable passive component 12 designed such that it amplifies the tension of the active component at resonance. A perforated membrane 13 is bonded to the actuator and the device has a general axis of symmetry 10 . Expansion and contraction of the actuator 14 causes an amplified movement 15 of the apertured membrane in a generally parallel direction. Depending on the design, the membrane itself can vibrate all in phase, with motion of one wavelength across its radius (ie, the central region can be out of phase with the edges) or motion of more than one wavelength. figure 2 (a) Shows details of the engagement of the actuator with the membrane associated with the device. The membrane is permanently attached to the actuator by means 16 such as adhesive bonding, laser welding, brazing, welding, and the lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com