Automatic grating steel reinforcement cage welding device

An automatic welding and steel cage technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, low production efficiency, poor quality, etc., and achieve low labor intensity and high work efficiency , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

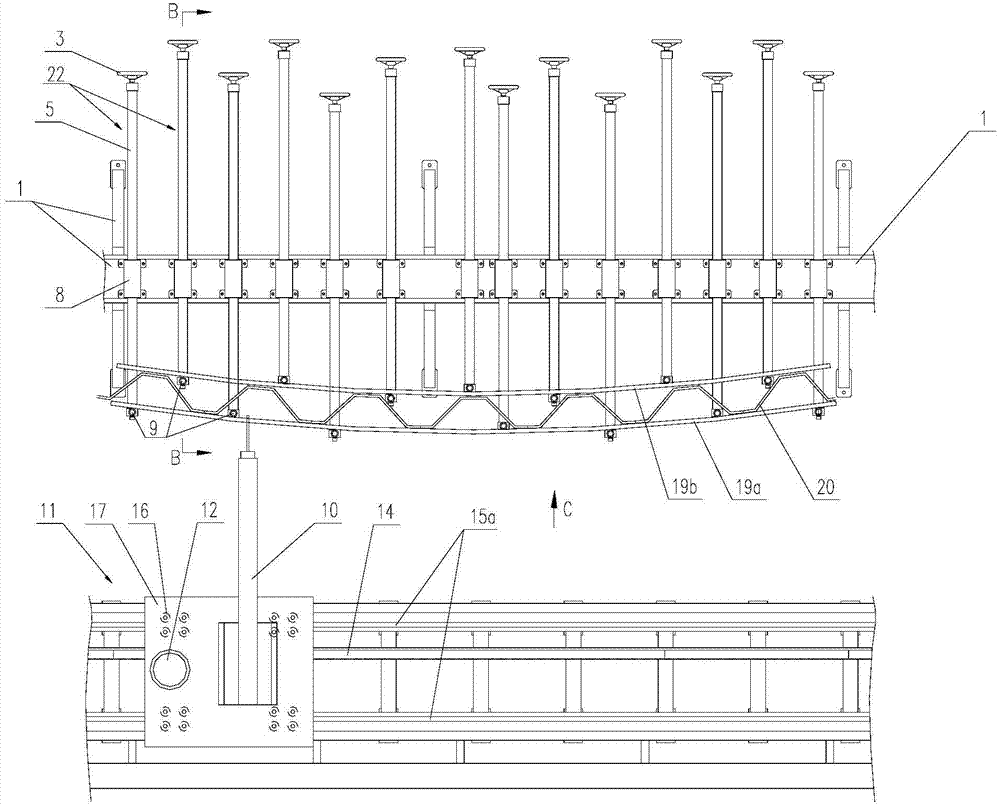

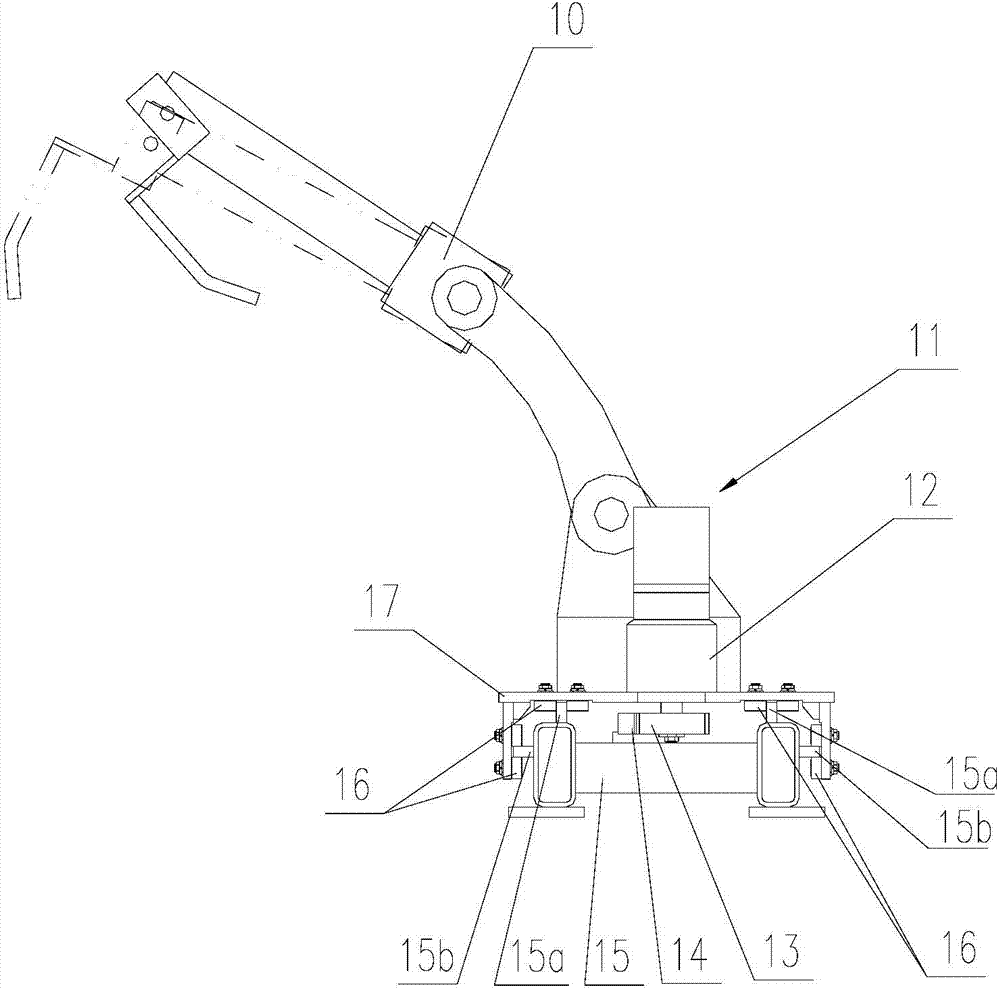

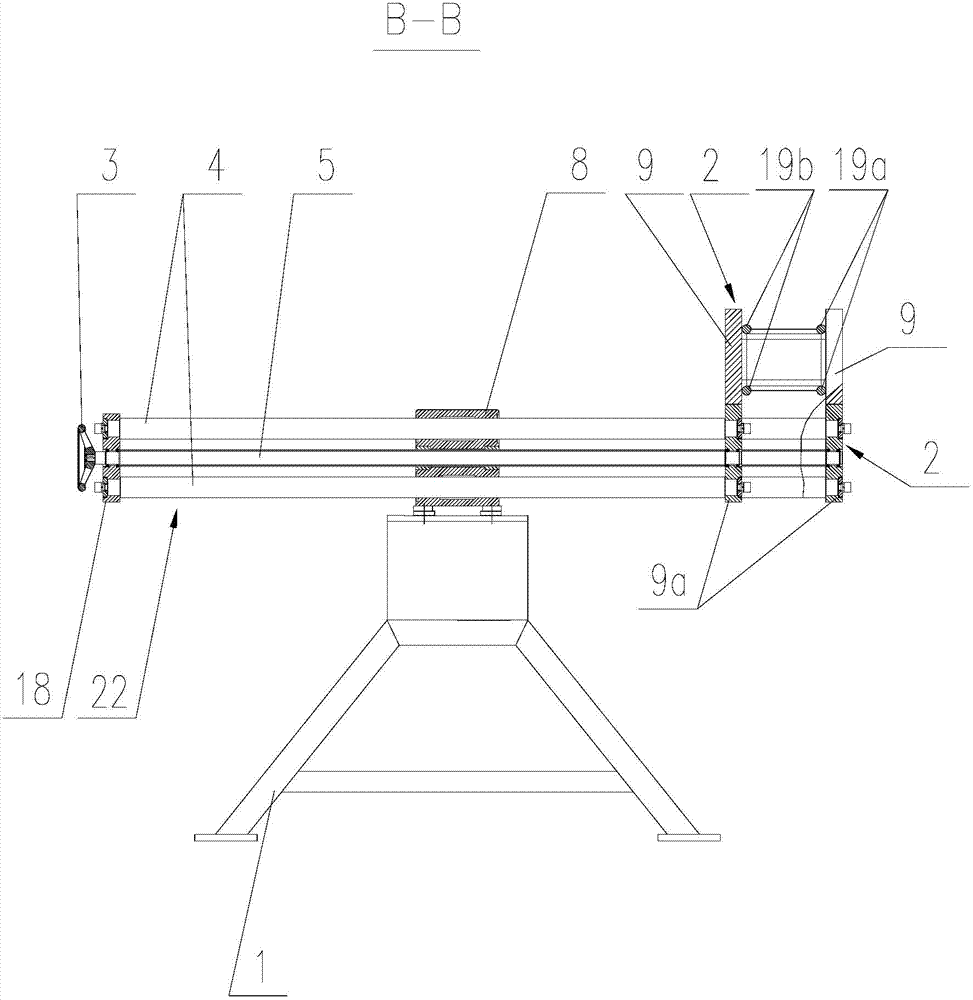

[0022] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] As shown in the figure, the present invention provides a kind of automatic welding equipment of grid reinforcement cage, and the automatic welding equipment of described grid reinforcement cage comprises: a plurality of welding adjustable clamps 2 with the same structure, and its structure all comprises: upper clamping The rod 9 and the upper clamping rod seat 9a connected to the bottom of the upper clamping rod 9; each upper clamping rod seat 9a is respectively connected with a reciprocating clamp adjustment device 22.

[0024] The upper clamping rods 9 of the plurality of welding adjustable fixtures 2 are respectively clamped on the arc edges on both sides of the outer arc main rib 19a and the arc edges on both sides of the inner arc main rib 19b of the grid steel cage 19; clamped on the two sides of the outer arc main rib 19a The adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com