Tunnel kiln powder distribution device

A technology of distribution device and tunnel kiln, which is applied to supply devices and manufacturing tools, etc., can solve the problems of time-consuming and laborious manual leveling of raw materials, and the flatness cannot be guaranteed uniform. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

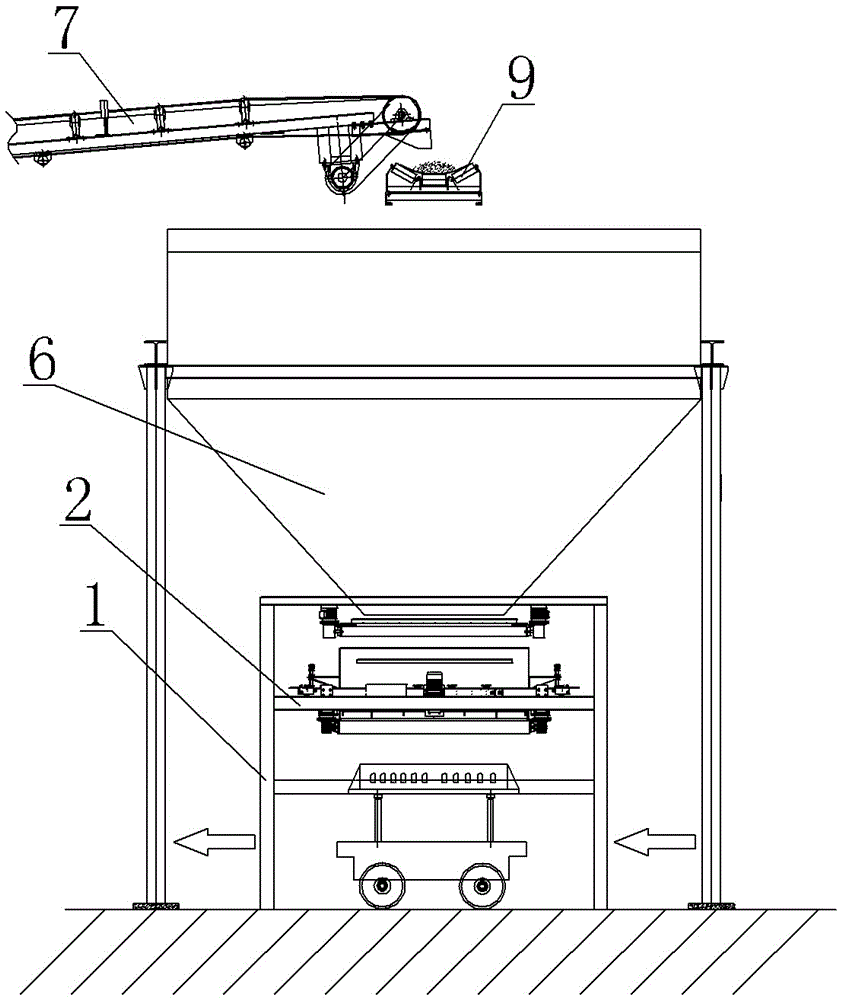

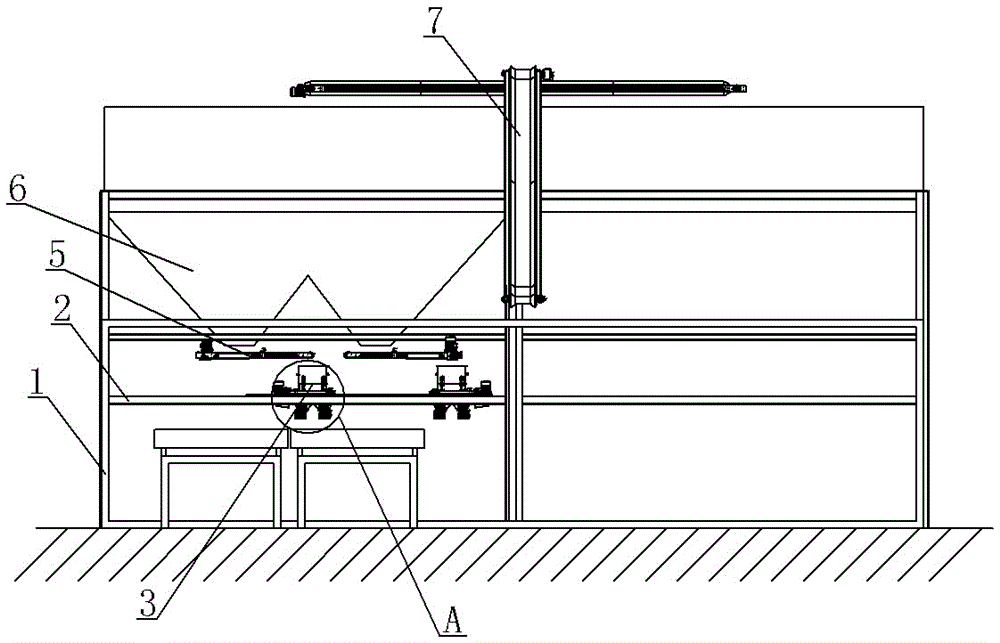

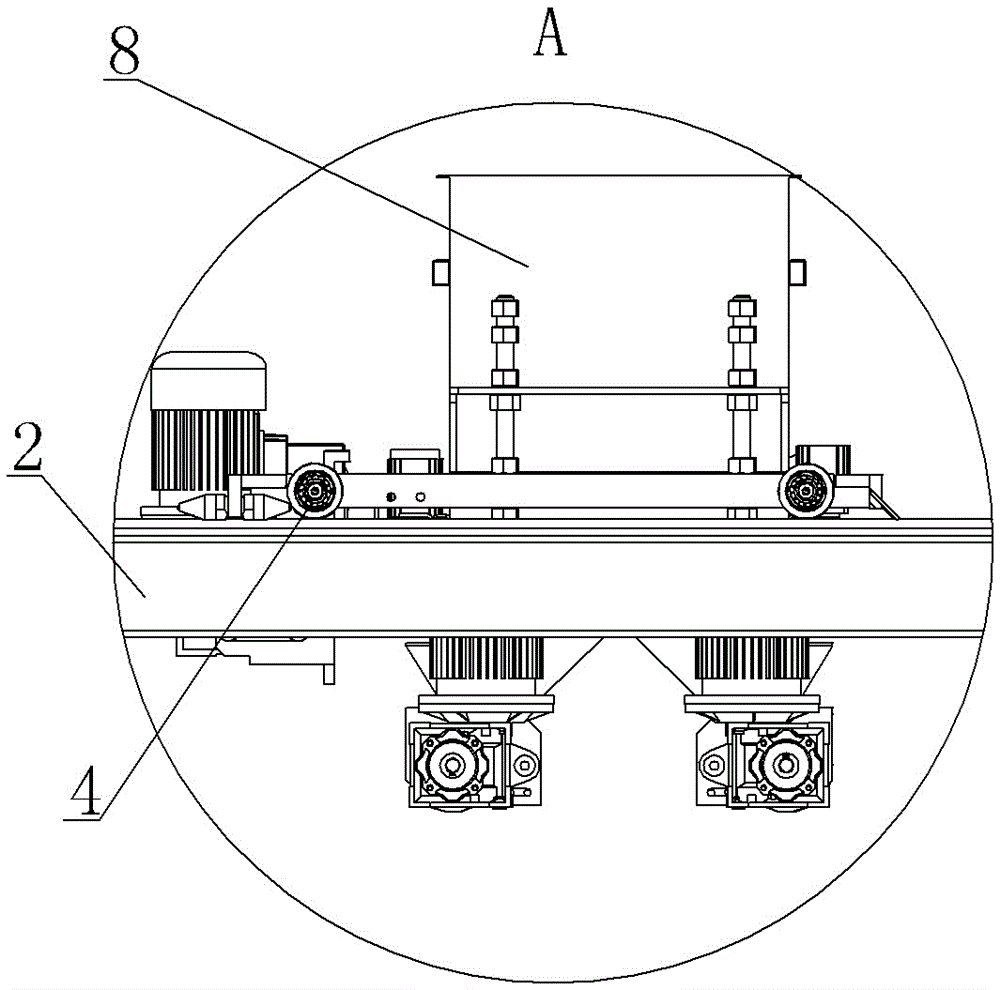

[0018] exist Figure 1~5 Among them, two rails 2 are arranged in parallel on the upper part of the main frame 1, and the main frame 1 is equipped with a distributing trolley 3, and the distributing trolley 3 is provided with four wheels 4, two of which are on one side of the distributing trolley 3, The other two are on the other side of the cloth trolley 3, and the four wheels 4 cooperate with the two rails 2 respectively to realize the mobile assembly of the cloth trolley 3 on the main frame 1. A driving device for driving the cloth trolley 3 to move is arranged between the fabric trolley 3 and the main frame 1 . The opening of the small material bin 8 of the cloth trolley 3 is upward, and the bottom of the small material bin 8 is provided with a strip-shaped discharge port. A pair of rollers are rotated in the small material bin 8, and the two rollers rotate relatively. Both rollers turn to the gap between the two. The gap between the pair of rollers is opposite to the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com