Feeding device of double-wheel slot milling machine and double-wheel slot milling machine

A feeding device and double-wheel milling technology are applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., which can solve the problems of few manufacturers, large pressure loss, and difficult maintenance, and achieve simple structure, low cost, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

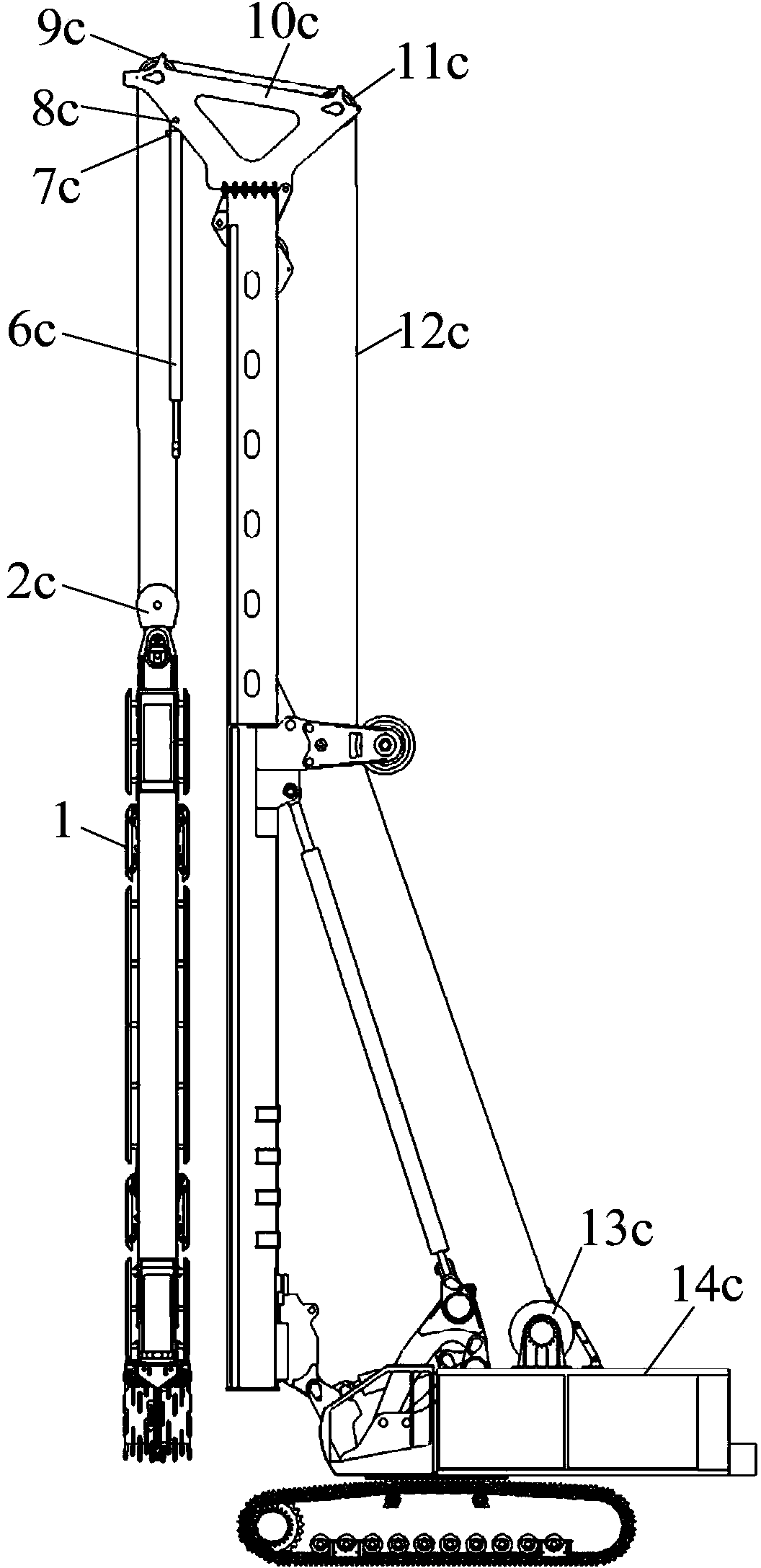

[0027] Such as figure 1 As shown, the feeding device of the double-wheel milling machine of the present invention includes an oil cylinder, the cylinder barrel of the oil cylinder is hinged with the mast of the double-wheel milling machine or the goose head that is arranged on the top of the mast of the double-wheel milling machine, and the piston rod of the oil cylinder is connected with the mast of the double-wheel milling machine. The milling device arranged under the oil cylinder is connected, and the milling device is the working device of the double-wheel milling machine.

[0028] The piston rod of the oil cylinder and the milling device arranged under the oil cylinder can be connected in various ways such as threaded connection, buckle connection, welding, hinged connection and the like. The extension and contraction of the piston rod of the oil cylinder realize the lifting and lowering of the milling device. Since the cylinder barrel of the oil cylinder is hinged with ...

Embodiment 2

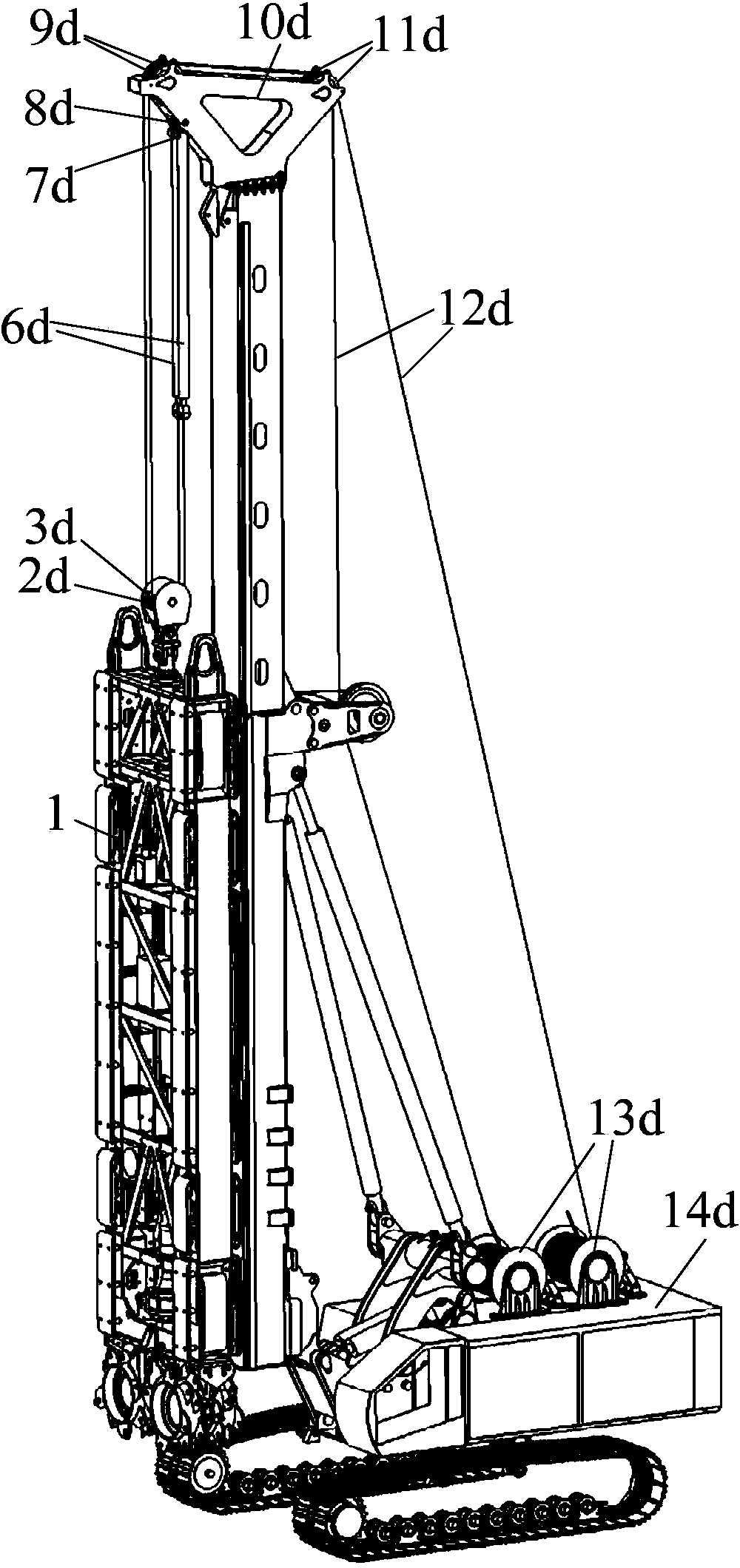

[0035] Such as figure 2 As shown, the feeding device of the double-wheel slot milling machine includes: lifting pulley block device 2d, oil cylinder 6d, displacement sensor 7d, shaft pin sensor 8d, goose head left pulley block 9d, goose head 10d, goose head right pulley block 11d, reel 13d, host 14d. The hoisting pulley block device 2d is located on the top of the milling device 1, and the hoisting pulley block device 2d has at least one pulley, and the number of the reel 13d and the oil cylinder 6d is two.

[0036] One ends of the two steel wire ropes 12d are respectively wound on the two reels 13d, and the other ends respectively go around the goose head right pulley block 11d, the goose head left pulley block 9d, the pulleys of the hoisting pulley block device 2d, and respectively connect with the pistons of the two oil cylinders 6d. The end of the rod is fixedly connected, that is, the specific winding method of the wire rope is: drum → goose head right pulley block → go...

Embodiment 3

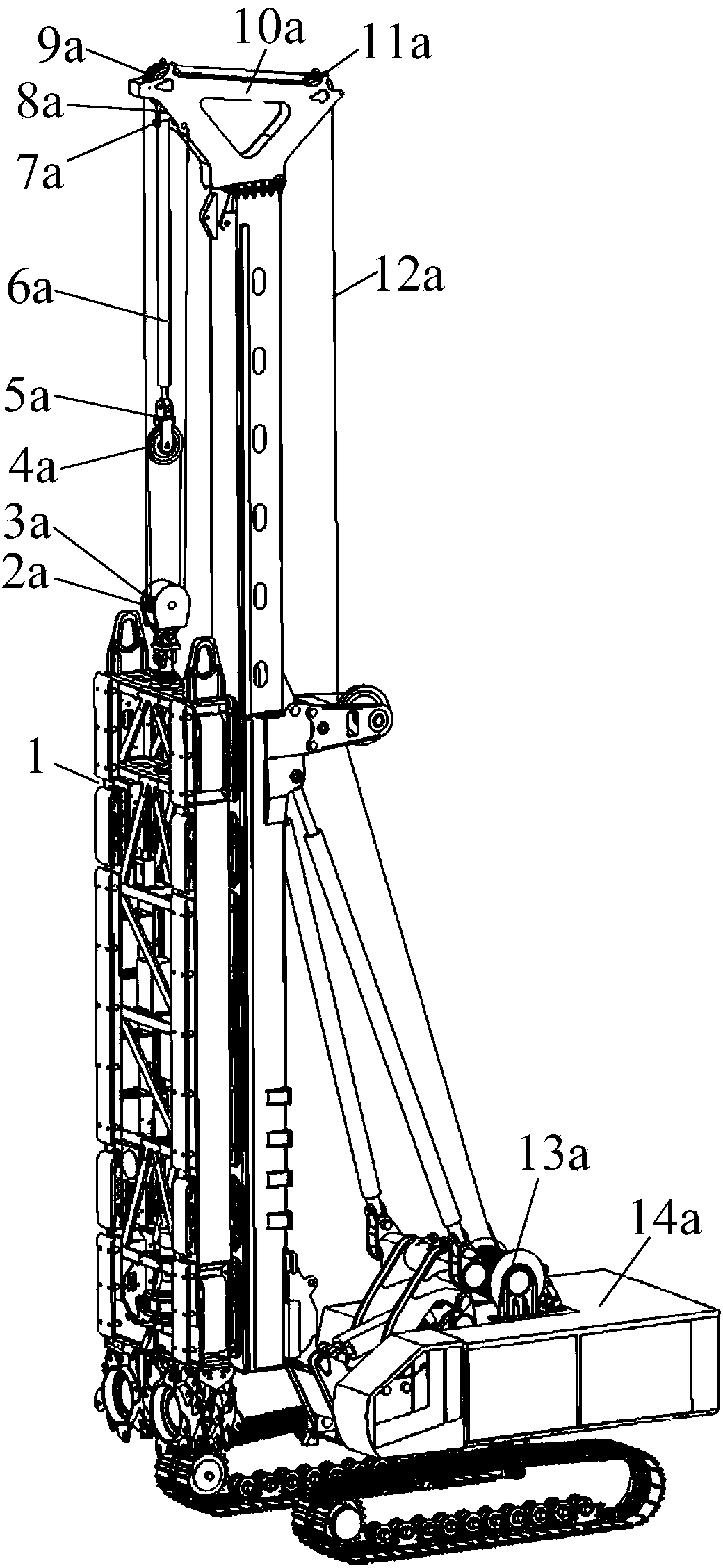

[0039] Such as image 3 As shown, the feeding device of the double-wheel milling machine includes: lifting pulley block device 2a, oil cylinder 6a, displacement sensor 7a, shaft pin sensor 8a, goose head left pulley block 9a, goose head 10a, goose head right pulley block 11a, reel 13a. Host 14a. The lifting pulley block device 2a is located on the top of the milling device 1, and the pulley 4a at the end of the oil cylinder is hinged to the piston rod of the oil cylinder 6a through the cross hinge block 5a. The lifting pulley block device includes a left pulley 2a and a right pulley 3a.

[0040] One end of the wire rope 12a is wound on the reel 13a, and the other end is wound around the right pulley block 11a of the goose head, the left pulley block 9a of the goose head, the left pulley 2a of the hoisting pulley block device, the pulley 4a at the end of the oil cylinder, and the right pulley of the hoisting pulley block device 3a and is fixedly connected to the left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com