Method for preparing polystyrene organic porous material with adjustable and controllable pore structure

A polystyrene and porous material technology, applied in the field of polymer materials, can solve problems such as time-consuming and laborious, and achieve the effects of broad application prospects, convenient operation, and simple and easy pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

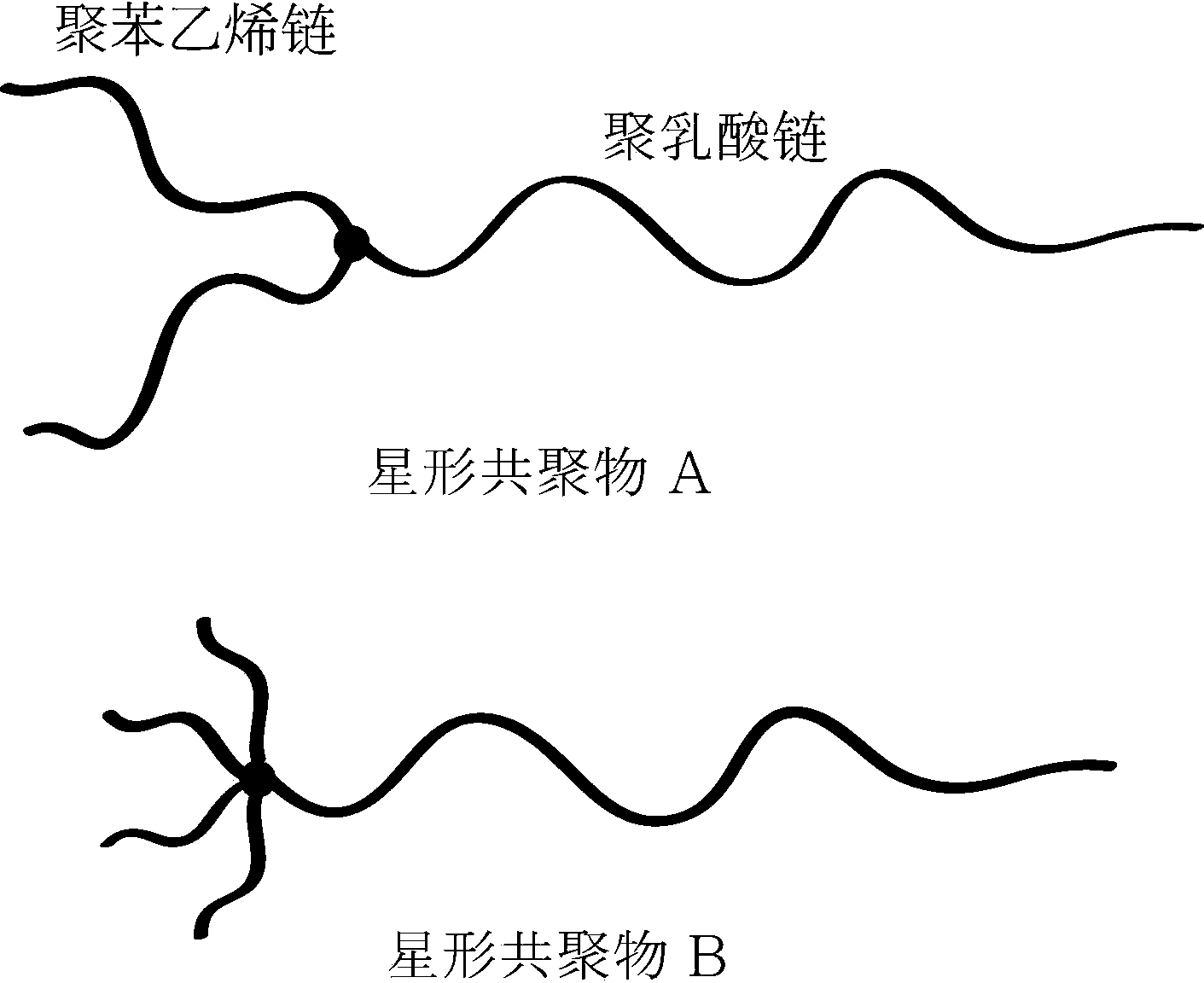

Method used

Image

Examples

Embodiment 1

[0024] Weigh the star-shaped copolymers A and B composed of polystyrene and polylactic acid in a ratio of 10:90, and then dissolve them uniformly with dichloromethane, and remove the organic solvent under reduced pressure; after microphase separation and macroscopic orientation at high temperature, hydrogen The polylactic acid phase was selectively etched away in an aqueous solution of sodium oxide to obtain a polystyrene organic porous material with an adjustable pore structure. The porous polystyrene block material has a pore diameter of 12.6 nm and a porosity of 119%.

Embodiment 2

[0026] Weigh the star-shaped copolymers A and B composed of polystyrene and polylactic acid in a ratio of 30:70, and then dissolve them uniformly with dichloromethane, and remove the organic solvent under reduced pressure; The polylactic acid phase was selectively etched away in an aqueous solution of sodium oxide to obtain a polystyrene organic porous material with an adjustable pore structure. The pore diameter of the porous polystyrene block material is 13.5 nm, and the porosity is 105%.

Embodiment 3

[0028] Weigh the star-shaped copolymers A and B composed of polystyrene and polylactic acid in a ratio of 50:50, and then dissolve them uniformly with dichloromethane, and remove the organic solvent under reduced pressure; after microphase separation and macroscopic orientation at high temperature, hydrogen The polylactic acid phase was selectively etched away in an aqueous solution of sodium oxide to obtain a polystyrene organic porous material with an adjustable pore structure. The porous polystyrene block material has a pore diameter of 14.7 nm and a porosity of 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com