Bi-component waterborne polyurethane coating composition

A water-based polyurethane, two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, layered products, etc., can solve the problems that cannot be cured into a film, and there are no reports of two-component water-based polyurethane coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods that do not indicate specific conditions in the following examples are usually carried out according to conventional conditions, or according to the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

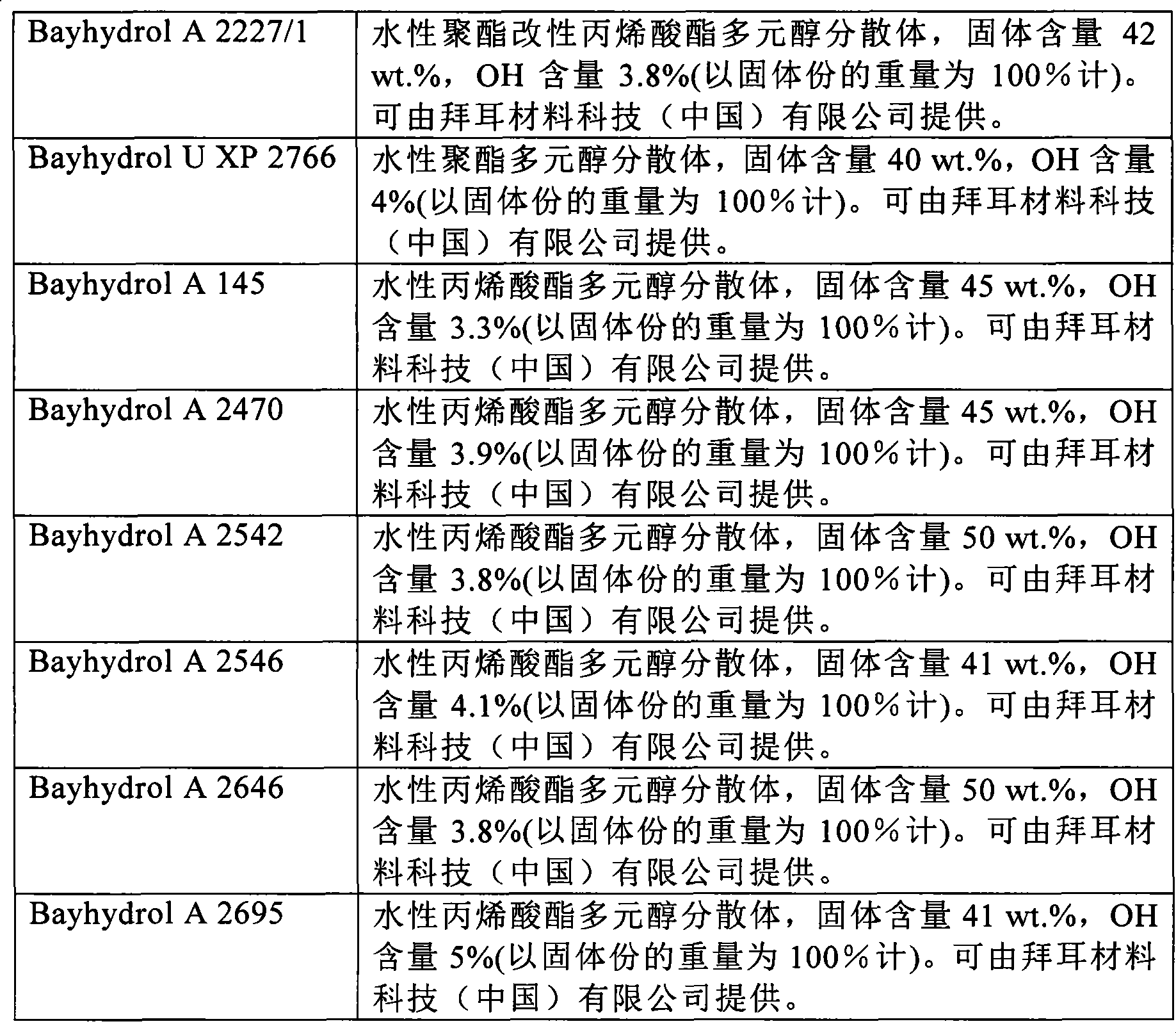

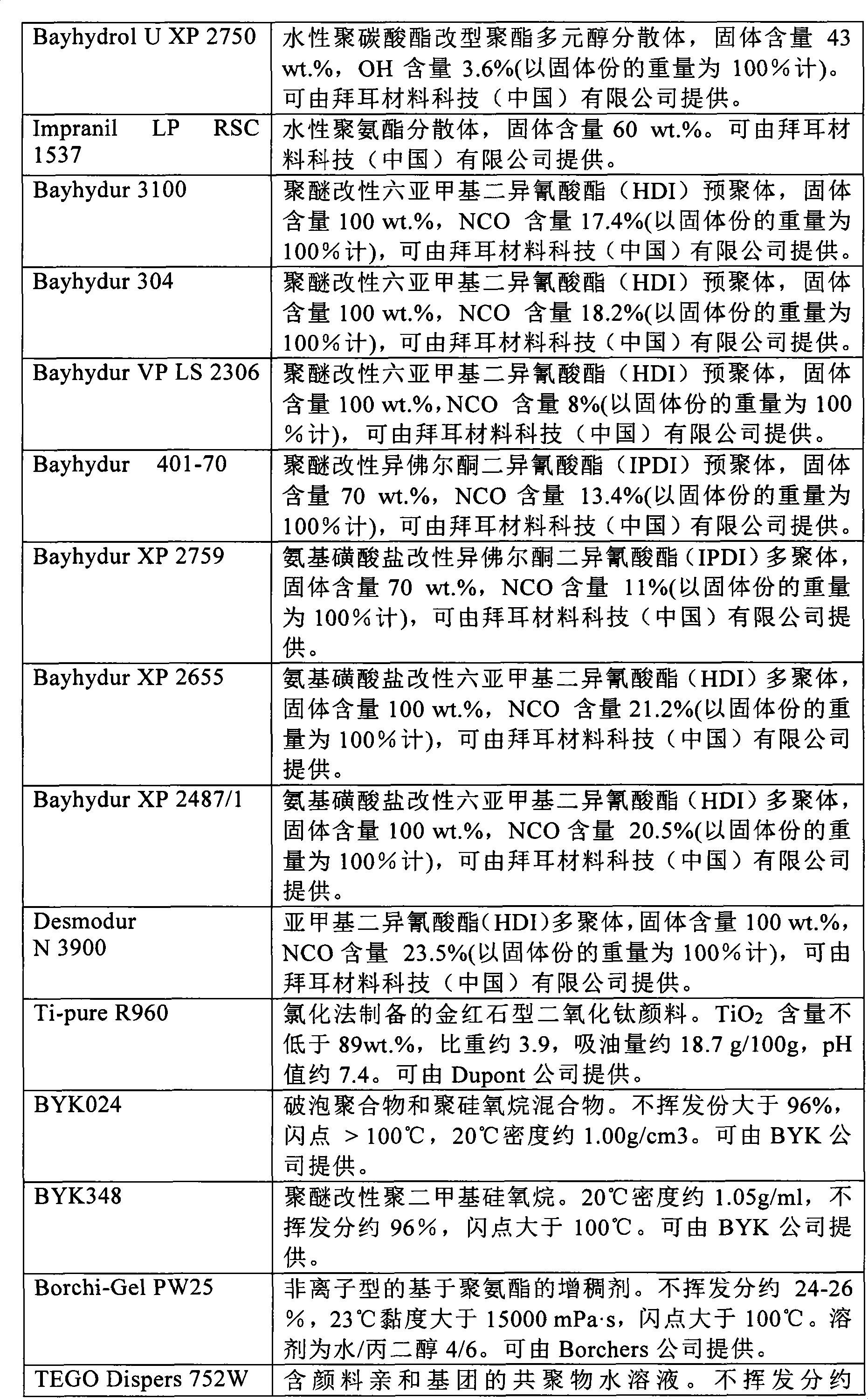

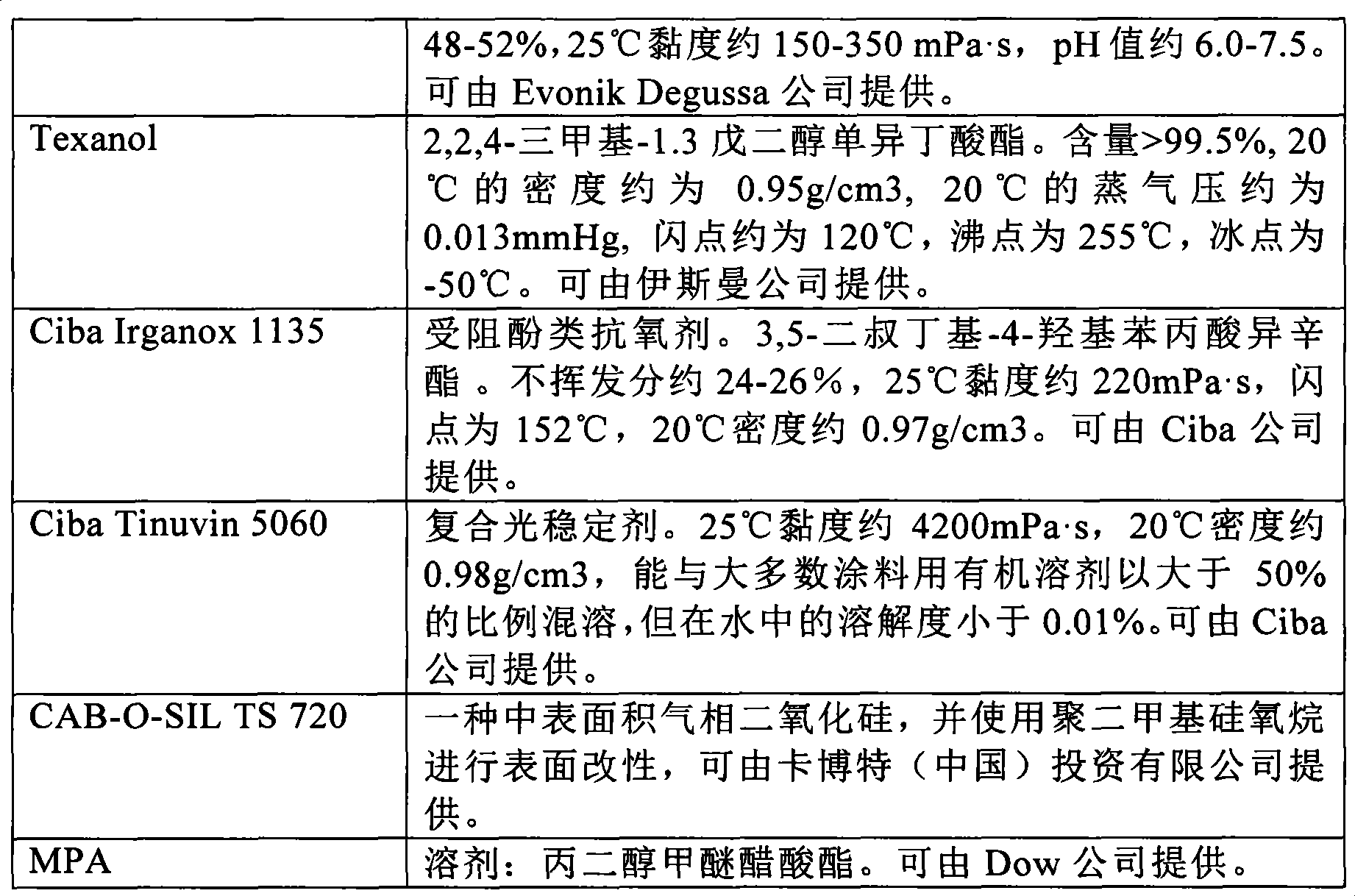

[0070] The raw materials mentioned in this text are shown in the table below.

[0071]

[0072]

[0073]

[0074] In each embodiment of the present invention, the high temperature yellowing resistance and other properties of the coating film prepared from the coating composition of the present invention were tested, as shown in Table 1 below. In Table 1, each test item and the corresponding test standard or method, the selection and pretreatment o...

Embodiment E1

[0111] Preparation of Component A

[0112]Put 50.00g Baydrol A2227 / 1 into the mixer container, stir at 1200rpm, slowly add 0.10g Borchi-Gel PW25, 0.2g BYK024, 0.7g TEGO Dispers752W, 13.8g R960, 5.45g deionized water, and then Increase the stirring speed to 3000rpm, and maintain this speed to disperse for 25 minutes. At this time, check the fineness. If the fineness is ≤15μm, stop high-speed dispersion; if the fineness is >15μm, continue high-speed dispersion until the fineness is ≤15μm. . When the fineness is ≤15μm, reduce the stirring speed to 1000rpm, slowly add 0.6g BYK348, and keep stirring at this speed for 5 minutes to complete the preparation of component A.

[0113] Component A was filtered through a 400-mesh filter and stored in a sealed container for 24 hours before use.

[0114] Preparation of Component B

[0115] Component B is Bayhydur XP2759, which is a sulfamate-modified isophorone diisocyanate (IPDI) polymer, diluted with MPA at a ratio of curing agent:MPA=3...

Embodiment E2

[0123] Preparation of Component A

[0124] Put 50.00g Baydrol A2227 / 1 into the mixer container, stir at 1200rpm, slowly add 0.10g Borchi-Gel PW25, 0.2g BYK024, 0.7g TEGODispers752W, 13.8g R960, 5.45g deionized water, and then increase Stir the speed to 3000rpm, and maintain this speed to disperse for 25 minutes. At this time, check the fineness. If the fineness is ≤15μm, stop the high-speed dispersion; if the fineness is >15μm, continue the high-speed dispersion until the fineness is ≤15μm. When the fineness is ≤15μm, reduce the stirring speed to 1000rpm, slowly add 0.6g BYK348, and keep stirring at this speed for 5 minutes to complete the preparation of component A.

[0125] Component A was filtered through a 400-mesh filter and stored in a sealed container for 24 hours before use.

[0126] Preparation of Component B

[0127] Component B is Bayhydur XP401-70, which is a polyether-modified isophorone diisocyanate (IPDI) polymer, diluted with MPA at the rate of curing agent / M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com