A Heat Treatment Process for High Strength and Toughness 27simn Steel

A high-strength toughness, high-tech technology, applied in the field of heat treatment of high-strength toughness 27SiMn steel, can solve problems such as insufficient plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A 27SiMn steel with the following mass percent chemical composition: 0.26%C, 1.20%Si, 1.26%Mn, 0.11%Cr, 0.06%Ni, 0.06%Cu, 0.01%Mo, 0.03%Ti, 0.014%P, 0.016% %S, the balance is Fe.

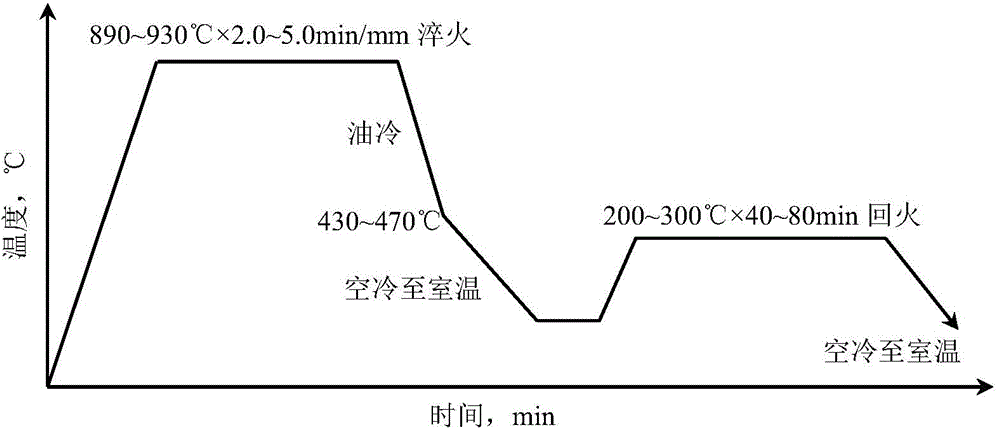

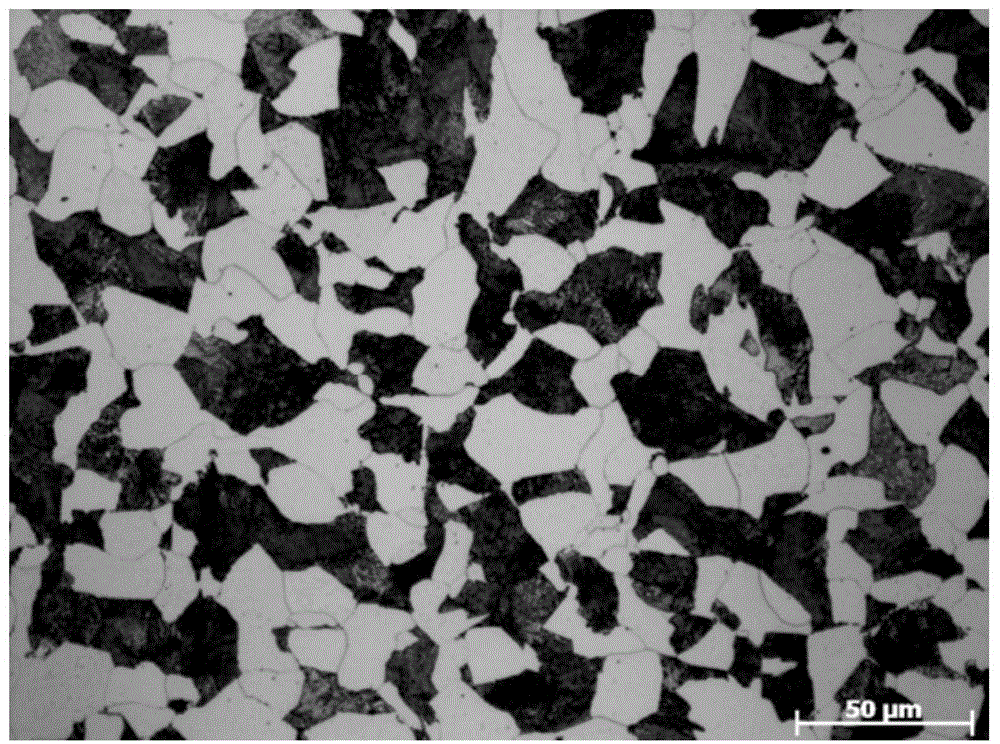

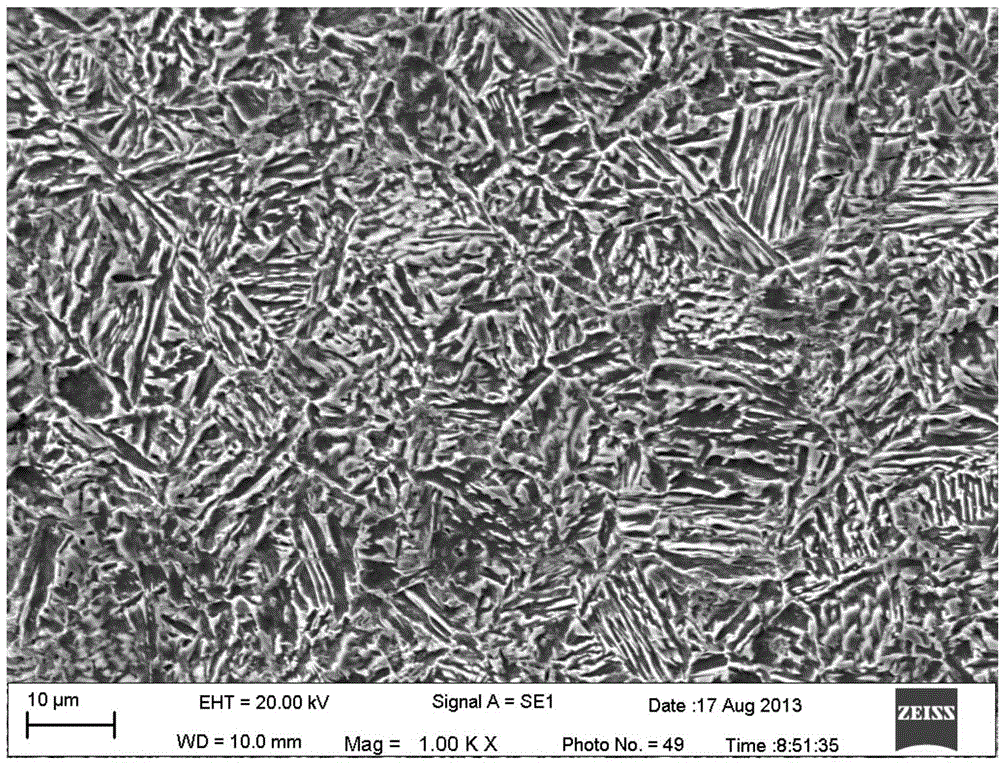

[0019] The process parameters of the staged quenching heat treatment used in the embodiment are shown in Table 1. The microscopic schematic diagram of the optical microscope of the metallographic structure of the hot-rolled material and the schematic diagram of the scanning electron microscope of the metallographic structure after the heat treatment of Example 1 are respectively as follows figure 2 and Figure 3a and Figure 3b shown. It can be seen that the structure of the hot-rolled material is pearlite + ferrite, and after heat treatment by stage quenching, the structure is bainite.

[0020] The mechanical properties of the hot-rolled material and conventional quenched and tempered heat treatment are shown in Table 2. The tensile strength of the hot-rolled material is 689MPa, the yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com