Construction method for drainage cement mixing pile

A technology of cement-soil mixing piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complex process, high cost, and long construction period, and achieve the effect of sufficient and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

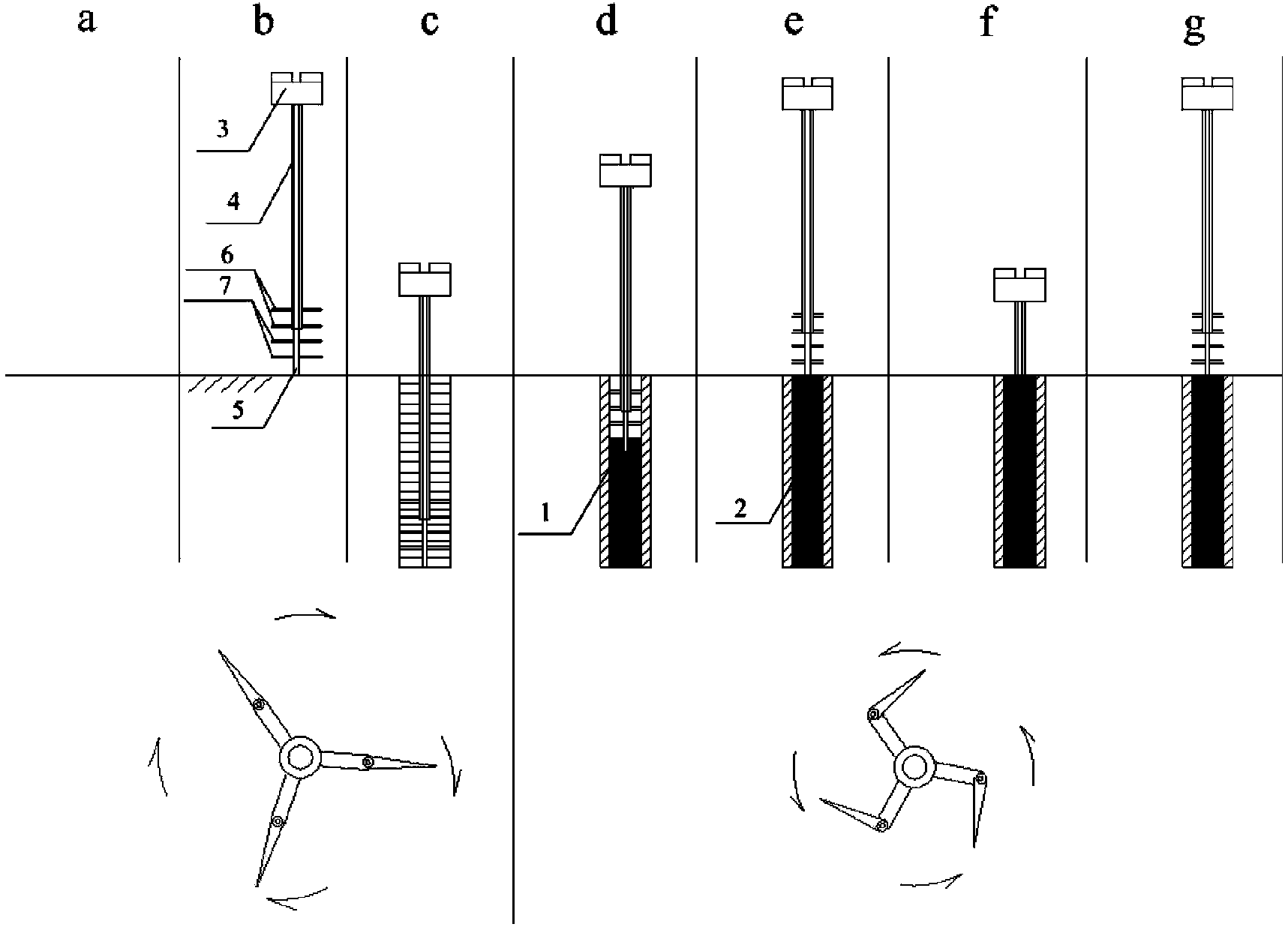

[0025] Utilize the principle that high liquid limit clay is mixed with low content (mixing ratio is generally less than 5%) cement or other modifiers (such as lime) to improve its permeability coefficient, combined with the new nail-shaped cement-soil two-way mixing pile The machine tool drives the outer drill pipe 4 and the inner drill pipe 5 to rotate in opposite directions in the foundation soil at the same time through the power device 1 on it, and the first sinking sprays low-volume (mixing ratio is generally less than 5%) cement or Other modifiers that can improve the permeability coefficient of clay, by controlling the direction of rotation, the fixed end 8 of the blade and the foldable blade 9 are in a stretched state to form a large-diameter drainage body 1, and a high dosage is sprayed during the rising process (the mixing ratio is generally not less than 10 %) cement or other solidifying agents that improve the strength of the soil, by rotating the outer drill rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com