Cast-in-place X-type concrete pile body strain monitoring method based on FBG (Fiber Bragg Grating) sensor

A concrete pile and strain monitoring technology, which is used in the testing of foundation structures, foundation structure engineering, construction, etc., can solve the problem that the continuous strain data of the pile body cannot be collected, the installation and layout of strain gauges are complicated, and there are many strain gauge export lines, etc. problems, to achieve the effect of recording and saving data conveniently and quickly, without electrical breakdown and burning, and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

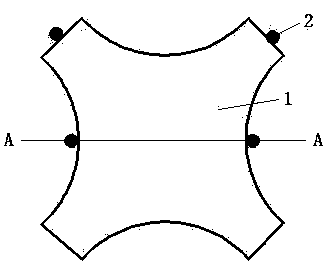

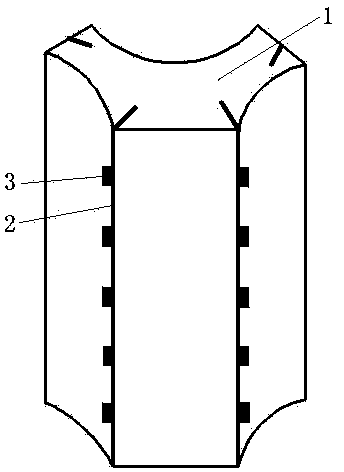

[0024] Embodiment: In this embodiment, the cast-in-place X-shaped concrete pile with optical fiber is arranged as figure 1 with figure 2 As shown, including the pile body 1, there are interconnected protrusions and depressions on the peripheral surface of the pile body 1, and four optical fibers 2 are laid on the surface of the pile body 1 along its axial direction, two of which are respectively along the adjacent The two protruding parts of the fiber optic cable are laid, and the other two are laid along the two opposite concave parts respectively, and the FBG sensor 3 is connected in series on the optical fiber 2 .

[0025] When in use, firstly polish the place where the FBG sensor will be placed with sandpaper, the purpose is to ensure that the surface of the concrete pile is clean and smooth, then coat a layer of epoxy resin on the surface, and then use sandpaper to polish the epoxy resin layer, so that the FBG sensor can be used with The epoxy resin is pasted more tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com