Non-guide foot of coal cutter

A guide slipper, non-guided technology, applied in earth-moving drilling, slitting machinery, propulsion, etc., can solve the problems of reducing equipment service life, long replacement and maintenance time, and increasing coal mining costs, reducing equipment loss and failure rate, improving coal mining production efficiency, and reducing the effect of machine failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

[0021] combine Figure 8 , on the side of the traditional coal mining machine equipped with support slide shoes 1, two identical support slide shoes 1 are installed in the middle of the two support slide shoes 1, and on the side where guide slide shoes 2 are installed, two guide slide shoes In the middle of the boot 2, two non-guide sliding shoes 3 that only play a supporting role and do not guide are installed.

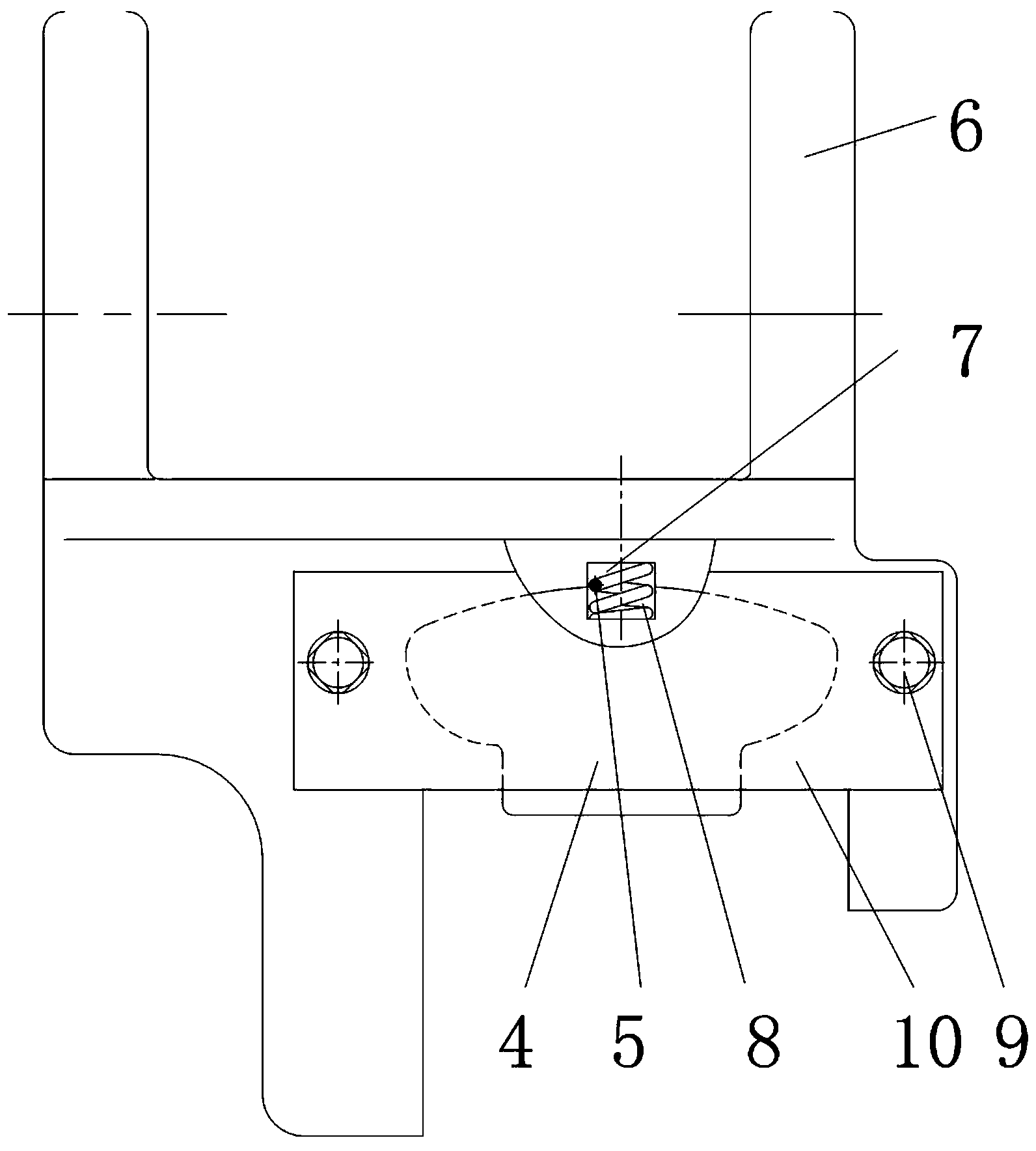

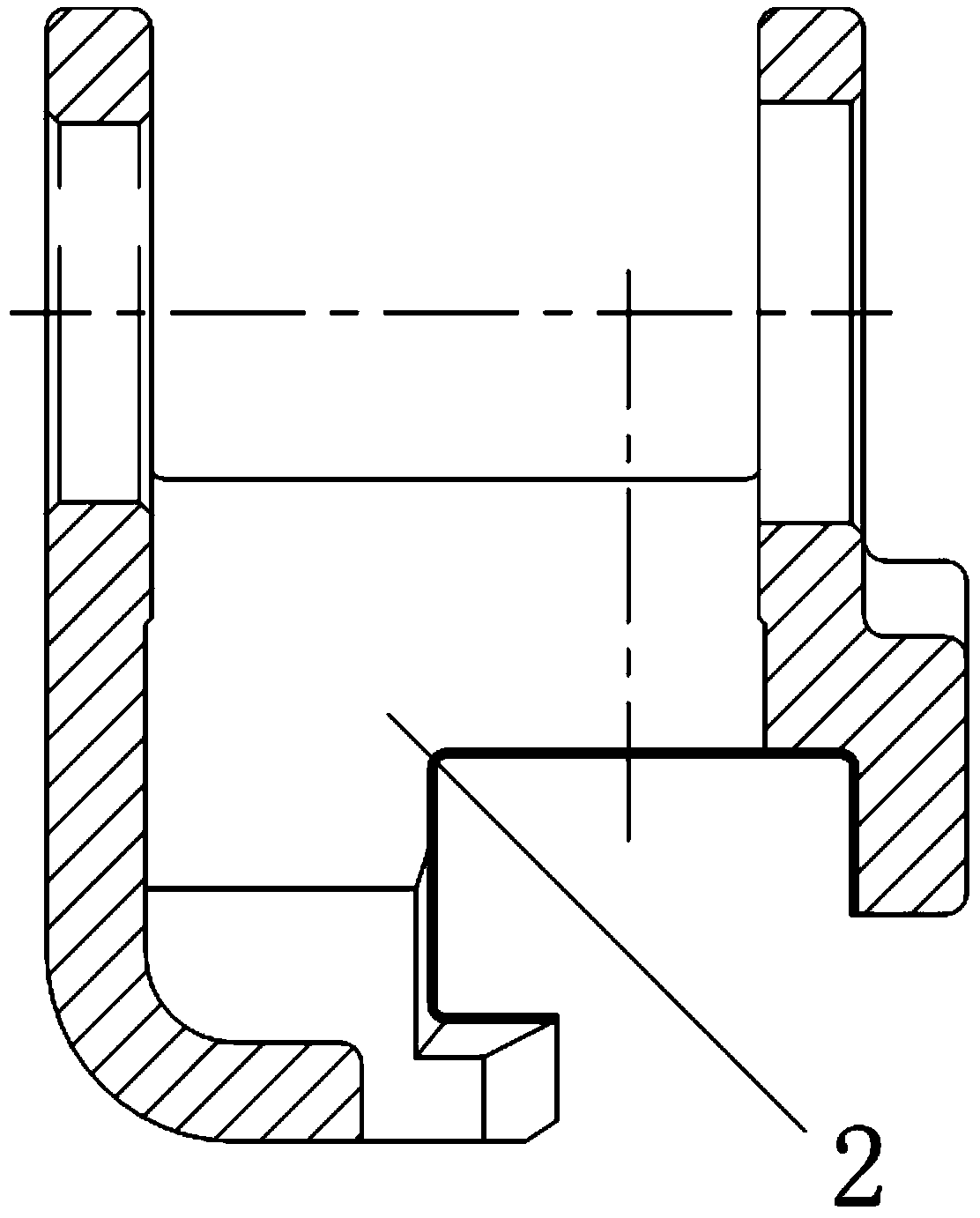

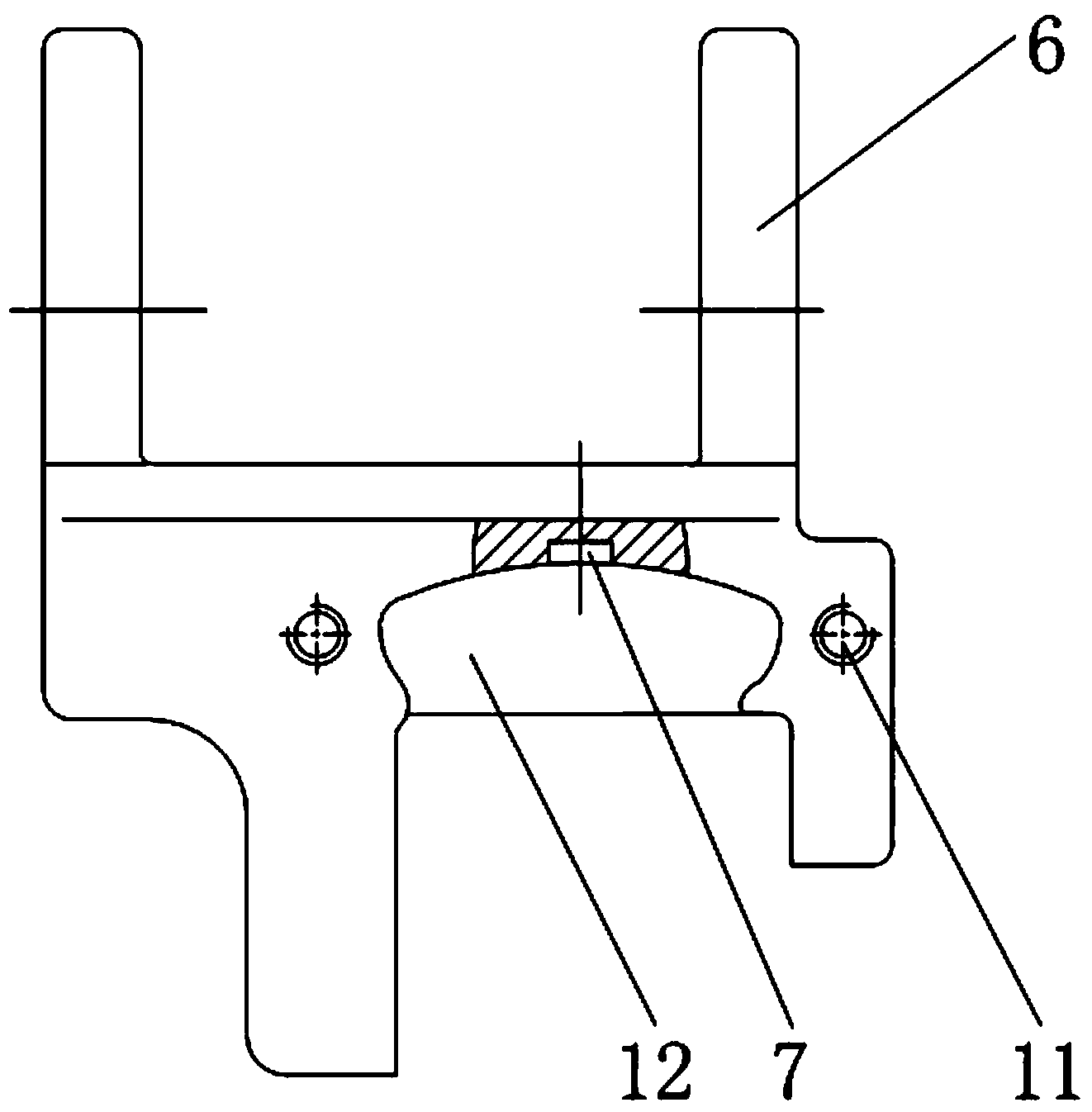

[0022] combine figure 1 , image 3 and Figure 4 There are two inverted U-shaped gaps on the two side surfaces of the non-guiding shoe 6 that is in contact with the two sides of the rack rail of the conveyor, which are arranged in the center of the two sides to prevent the rack from colliding with the shearer when the shearer is miter-cutting. The guide shoe 2 interferes; the surface of the non-guide shoe body in contact with the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com