Experimental device and method for evaluating the drag reduction effect of bionic non-smooth surfaces

A non-smooth surface, smooth surface technology, applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc. Simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

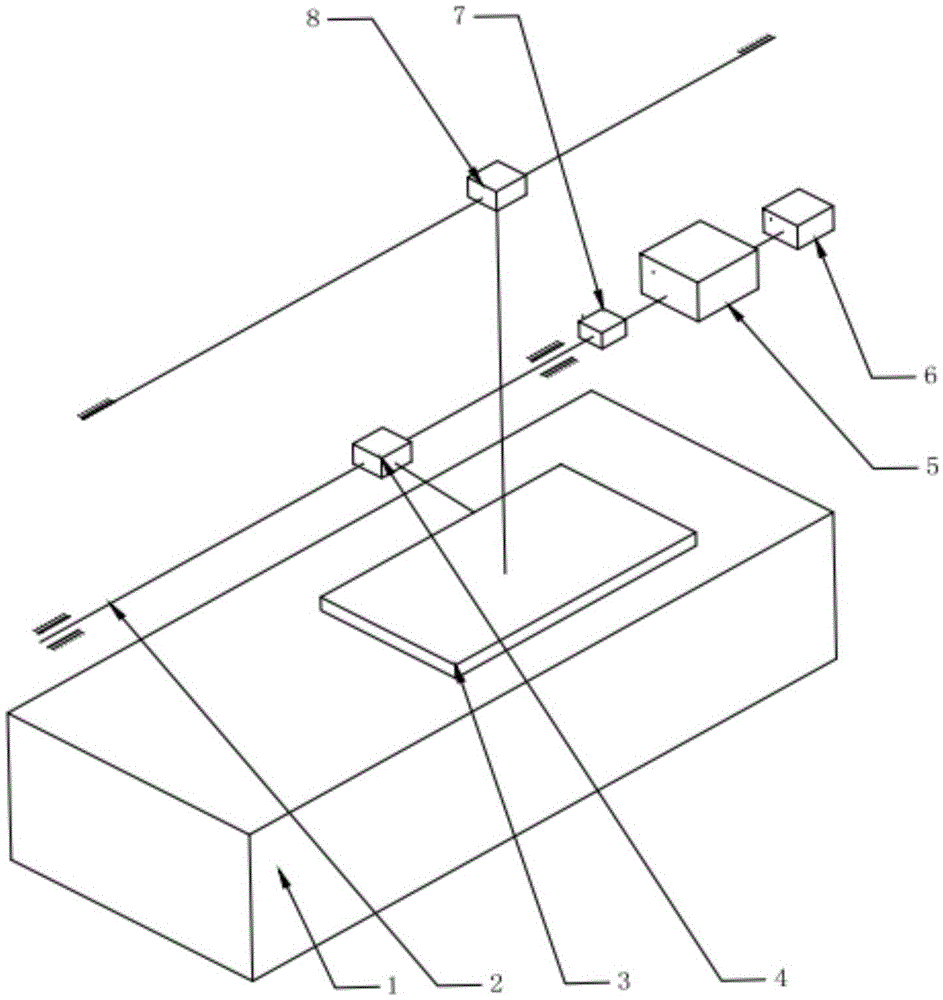

[0017] combine figure 1 , comprising a stepper motor 5, a stepper motor driver 6, an elastic diaphragm coupling 7, a test plate model 3, a screw nut mechanism and a pool; wherein the nut 4 is fixedly connected with the test plate model 3, along the lead screw 2 Do translational movement.

[0018] The working principle of the present invention is:

[0019] The stepper motor 5 drives the lead screw 2 to rotate, and the test flat model 3 fixedly connected with the nut 4 moves together. At the same time, the driving power of the stepping motor 5 and the speed of the test flat model 3 are recorded. By comparing the same driving power The speed of the non-smooth surface model and the smooth surface model is used to evaluate the drag reduction effect of the bionic non-smooth surface, and it is also used to evaluate the bionic non-smooth surface by comparing the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com