Air particulate matter sampler capable of automatically changing membrane

A technology for air particulate matter and automatic membrane change, which is applied in the direction of sampling devices, etc., can solve the problems of increasing personnel investment and increasing the labor intensity of operators, and achieves the effects of good portability, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

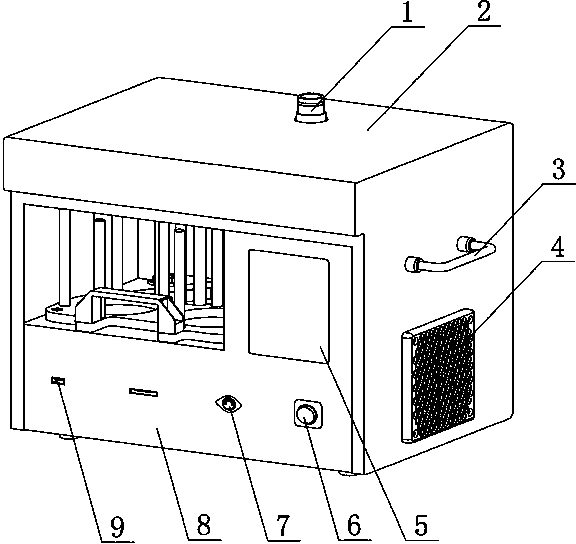

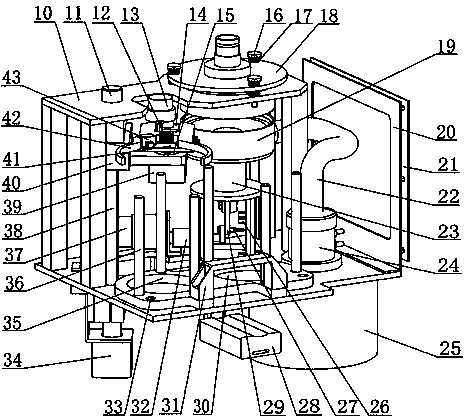

[0017] Such as figure 1 , 2 The air particle sampler with automatic membrane change shown includes a housing 2 and a membrane storage mechanism installed in the housing, a lifting and clamping rotation mechanism, a detection mechanism, and a control device. The membrane storage mechanism includes a membrane storage mechanism installed in the housing The filter membrane library 35 to be tested and the measured filter membrane library 30 on the body board; the lifting clamping and rotating mechanism includes a lifting device installed on the inner plate of the housing and a clamping device and a rotating device installed on the lifting mechanism; The control device is connected with the detection mechanism and the lifting, clamping and rotating mechanism.

[0018] The housing 2 is composed of an upper casing, a front panel 8, a bottom plate and an inner plate of the housing, the upper casing is combined with the front panel and the bottom plate to form a quadrilateral, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com