Six-channel air particle sampling device

A technology of air particulate matter and sampler, applied in the direction of sampling devices, etc., can solve the problems of loss, inconvenient operation, bulky instrument, etc., and achieve the effect of light weight, easy movement, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

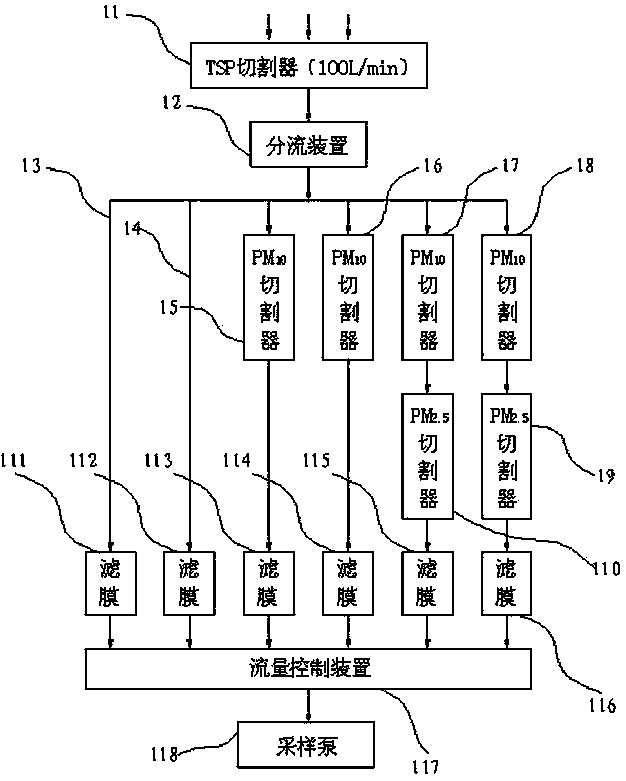

Embodiment 1

[0027] like figure 1 As shown, the sampling pump 118 sucks ambient air containing particulate matter into the TSP cutter 11 at a flow rate of 100 L / min. Under this flow rate, the TSP cutter 11 excludes particulate matter with an aerodynamic particle size greater than 100 μm from the sampler, The particles with an aerodynamic diameter of ≤100 μm enter into the flow splitting device 12 along with the airflow. The flow control device 117 precisely controls the flow rate entering the six air paths to be 16.67L / min, the sampling filter membrane is a standard filter membrane with a diameter of 47mm, and the splitter device 12 ensures that the air flow entering each air path is evenly distributed according to the principle of isotropy. The connecting rod 13 and the connecting rod 14 are directly connected to the filter membrane 111 and the filter membrane 112 , and the particles trapped on the filter membrane 111 and the filter membrane 112 are TSP. The PM10 cutter 15 and the PM10 c...

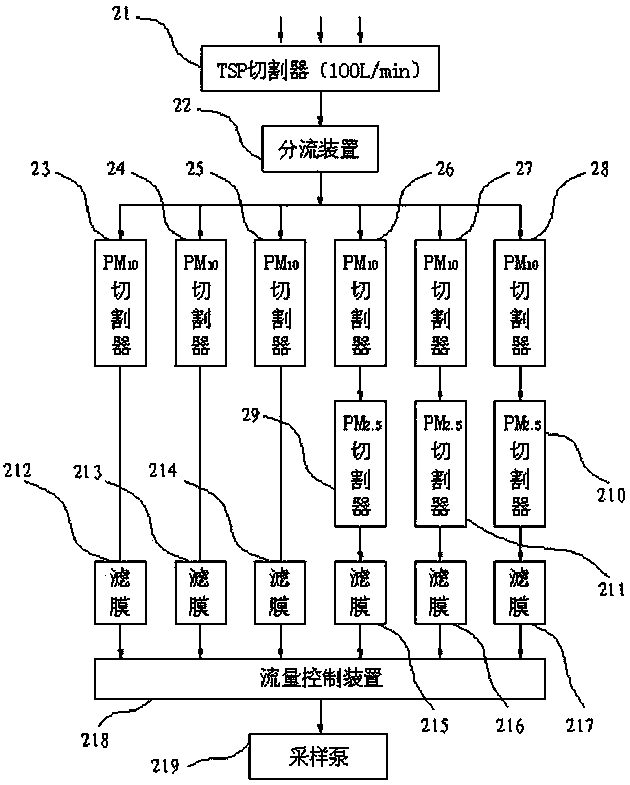

Embodiment 2

[0034] like figure 2 As shown, the sampling pump 219 sucks ambient air containing particulate matter into the TSP cutter 21 at a flow rate of 100 L / min. Under this flow rate, the TSP cutter 21 excludes particulate matter with an aerodynamic particle size greater than 100 μm from the sampler, The particles with an aerodynamic diameter of ≤100 μm enter into the flow splitting device 22 along with the airflow. The flow control device 218 precisely controls the flow rate entering the six air paths to be 16.67L / min, the sampling filter membrane is a standard filter membrane with a diameter of 47mm, and the splitter device 22 ensures that the air flow entering each air path is evenly distributed according to the principle of isotropy. The PM10 cutter 23 , the PM10 cutter 24 and the PM10 cutter 25 are directly connected to the filter membrane 212 , the filter membrane 213 and the filter membrane 214 . The PM10 cutter 23, the PM10 cutter 24 and the PM10 cutter 25 intercept the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com