Multi-amplitude ultrasonic pulling-twisting testing device for testing mechanical properties of hard and crispy materials

A technique for tensile and torsion testing of hard and brittle materials, applied in the directions of testing material strength by applying stable torsion force and testing material strength by applying stable tension/compression, etc., to achieve the effect of flexible and simple operation, reasonable structure and strong intuitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

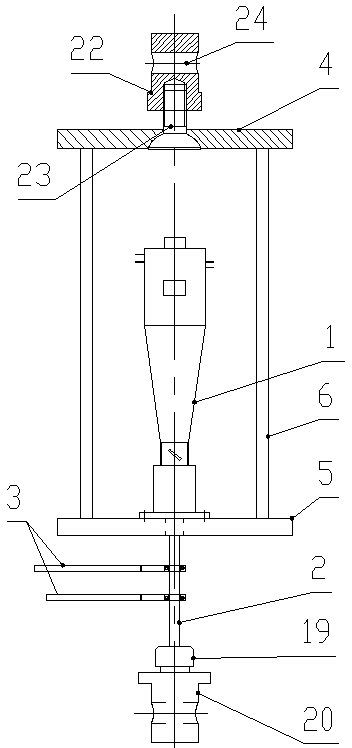

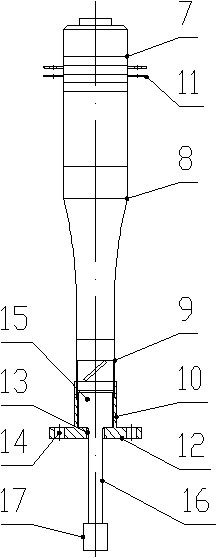

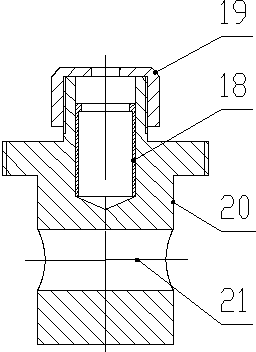

[0022] like figure 1 , figure 2 and image 3 As shown, the multi-amplitude ultrasonic tension and torsion test device for testing the mechanical properties of hard and brittle materials of the present invention includes a support frame, an upper connector, a lower connector and an ultrasonic vibration system 1, and the ultrasonic vibration system 1 is arranged on the support frame. The upper connector is set on the upper end of the support frame, the lower connector is located directly below the support frame, and the rod-shaped sample 2 is clamped between the lower end of the ultrasonic vibration system 1 and the lower connector, and the sample 2 is vertically arranged. 2 A strain measuring plate 3 is provided on the upper side and the lower side of the middle position respectively.

[0023] The support frame includes a top plate 4 and a bottom plate 5 arranged horizontally, and at least two vertical support rods 6 are arranged between the lower surface of the top plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com