Cable conductor DC-resistance testing device and testing method

A technology for DC resistance testing and cable conductors, which is applied to measuring devices, measuring resistance/reactance/impedance, and measuring electrical variables, etc. It can solve the problems of poor repeatability, difficulty in maintaining consistency, and volatility of conductor resistance testing, and avoid test data. Inauthentic, save material waste cost, overcome the effect of large detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

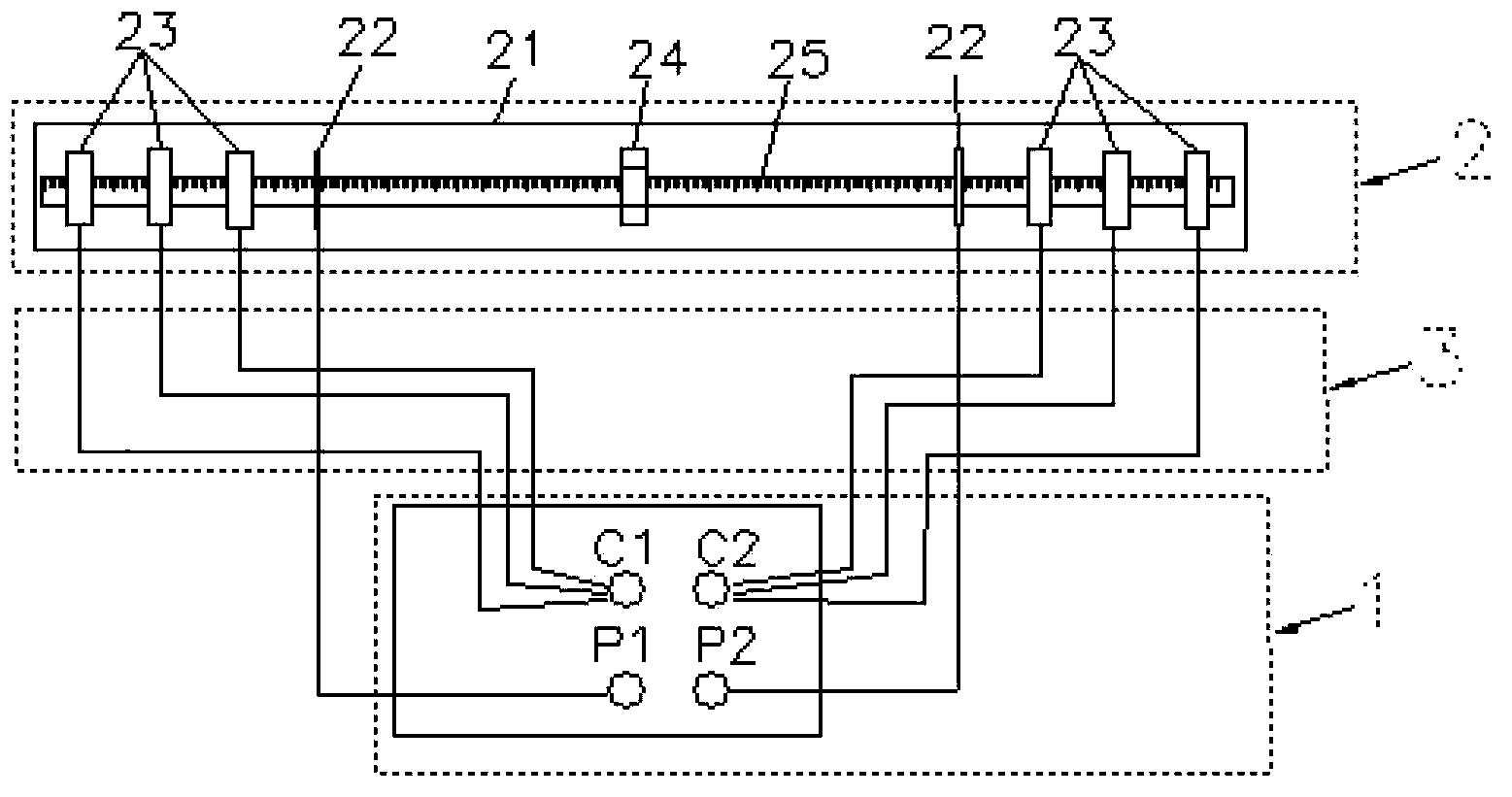

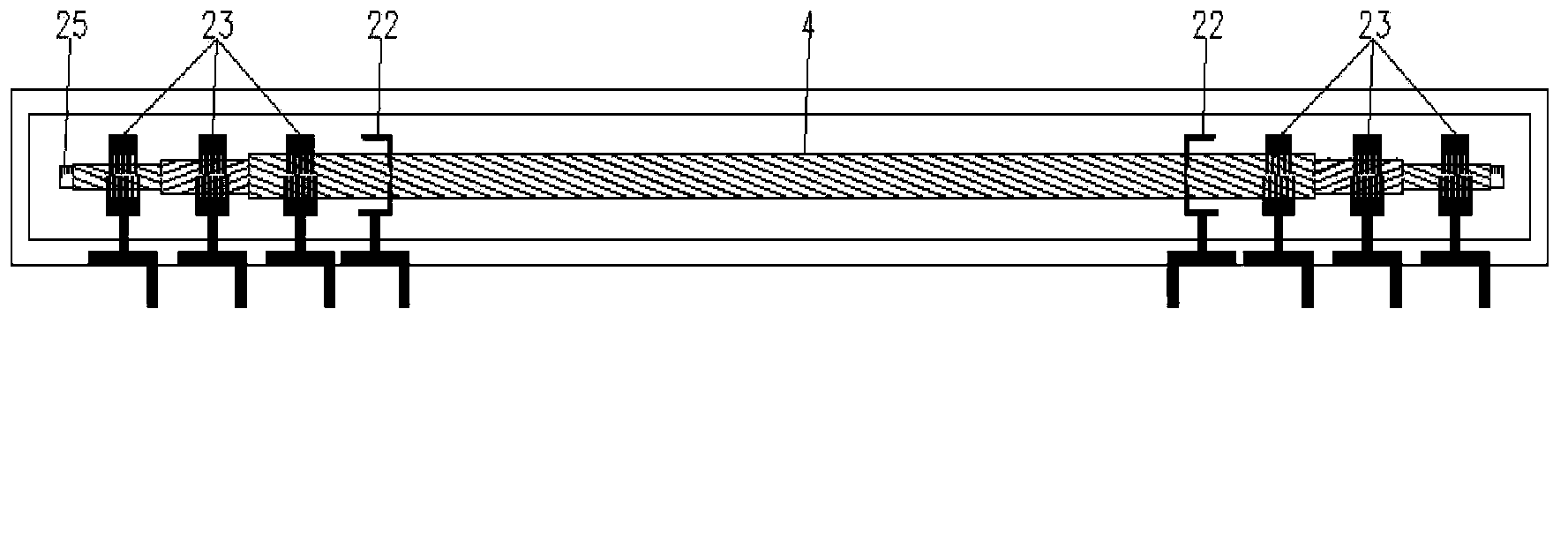

[0029] See figure 1 and figure 2 , the cable conductor DC resistance testing device in this embodiment includes a double-arm bridge 1 , a sample holder 2 and a connecting wire 3 that electrically connects the two. The sample holder 2 includes a base 21 with a scale 25 , a voltage electrode holder 22 , a current electrode holder 23 , a support bracket 24 and a scale 25 . The voltage electrode clamp 22 and the current electrode clamp 23 are detachably assembled on the base 21 and slidably fixed to the base 21 . Of course, one end can be fixed and the other end can be slidably fixed. The voltage electrode clamps 22 and the current electrode clamps 23 are arranged in pairs at both ends of the base 21; the current electrode clamps 23 are at least two pairs, and the specific number of pairs is equal to the number of layers of the conductors of the cable to be tested, and the current electrodes located on the same side of the base 21 The clamps 23 are connected two by two. Each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com