Electric power tunnel cable monitoring system with self-check and hot swap functions

A technology for power tunnels and monitoring systems, applied in electrical program control, comprehensive factory control, measuring devices, etc., can solve problems such as difficult fault location, hidden dangers of uncertain maintenance work, high maintenance costs, etc., to simplify maintenance work and shorten maintenance Time, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

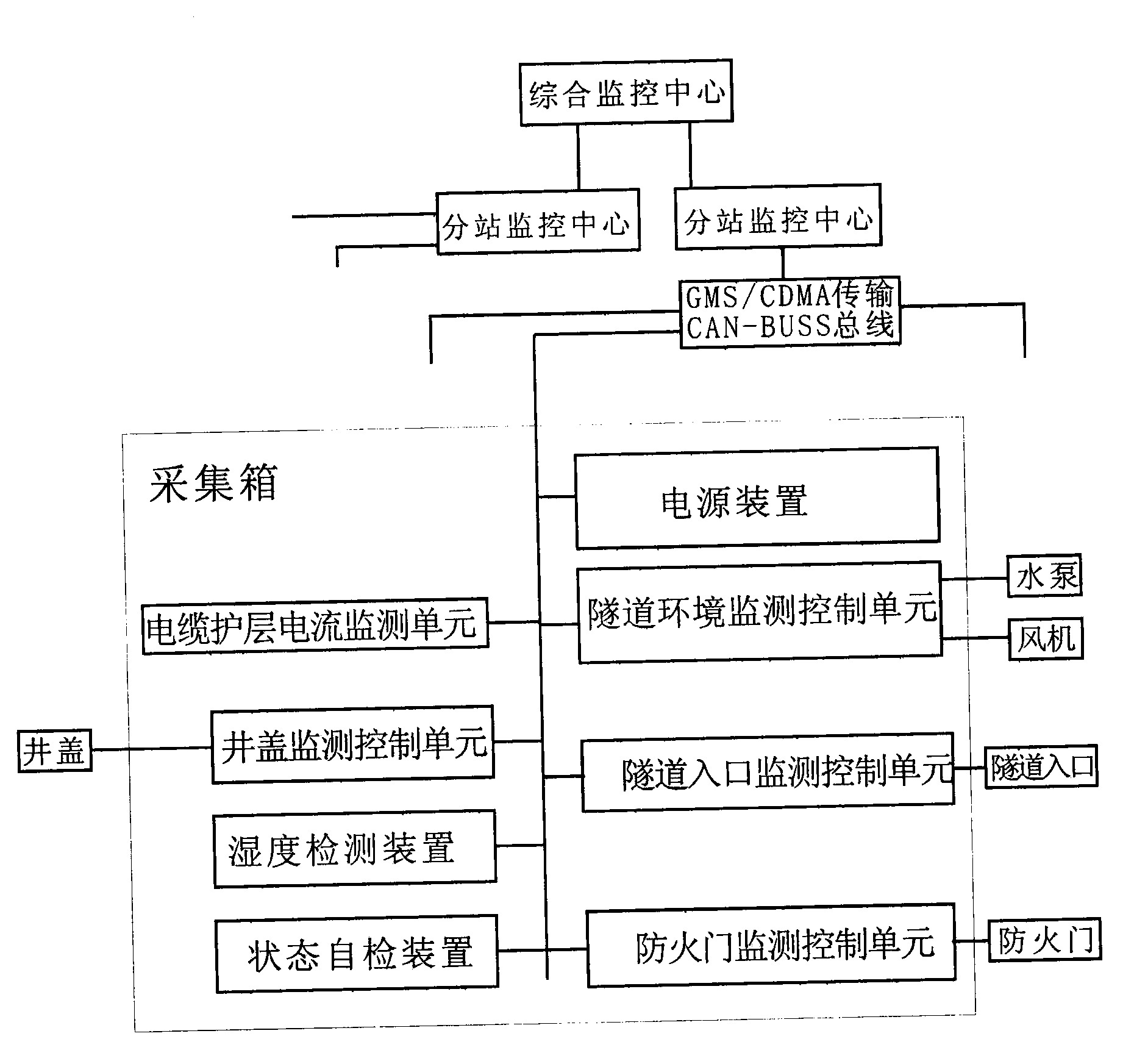

[0034] The present invention forms a network according to the above method: the state monitoring and equipment control unit, the data transmission unit, and the data monitoring center are connected in series.

[0035] The cable grounding wire monitoring is mainly used for monitoring the grounding circulation of the metal sheath of the power system 110KV and above. The design of the cable system is based on the tunnel laying method used for cable laying.

[0036] The communication between each detection device and the system and the power supply of each detection device of the present invention share a pair of armored power twisted pair communication cables with a thickness of 0.5 square millimeters. It is not necessary to establish optical network communication, and the communication distance is greater than 5 kilometers. Twisted-pair communication cables can connect up to 127 devices with bus technology, no optical network failure and low-voltage current interface failure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com