Field emission light source

A field emission and light source technology, applied in the direction of fluorescent screen lamps, lamp parts, etc., can solve the problems of unevenness, performance degradation, micro-tip damage, etc., and achieve the effect of stable light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

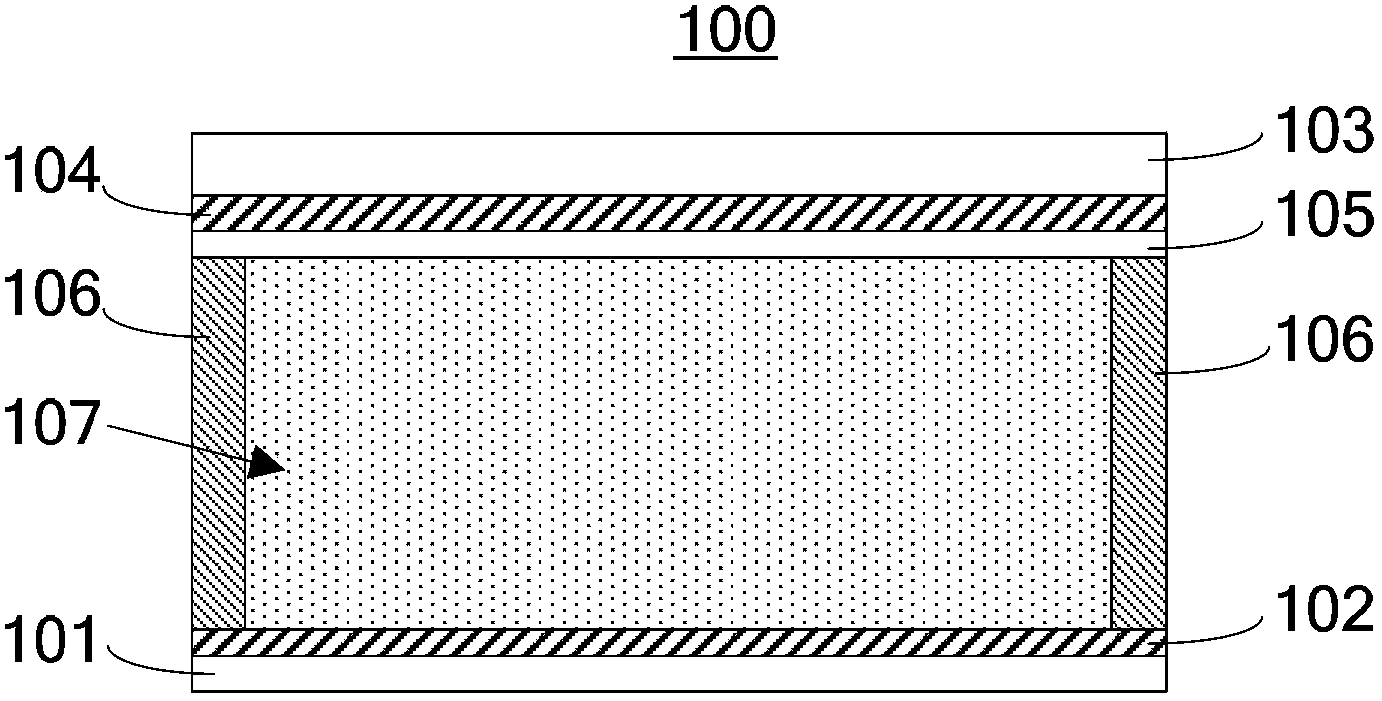

[0043] Such as figure 2 The field emission light source 100 shown includes a cathode substrate 101 , a cathode conductive layer 102 , an anode substrate 103 , an anode conductive layer 104 , a light emitting layer 105 , side walls 106 , a sealed cavity 107 and nitrogen gas 108 . Wherein, the material of the cathode substrate 101 is transparent glass; the material of the cathode conductive layer 102 is an ITO film with a thickness of 1 μm; the material of the anode substrate 103 is transparent conductive glass; the material of the anode conductive layer 104 is an ITO film with a thickness of 1 μm; Layer 105 is Y 2 o 3 :Eu, Y 2 SiO 5 :Tb and Y 2 SiO 5 :Ce is a three-color phosphor that emits white light and is a mixture of the three.

[0044] The cathode conductive layer 102 and the cathode substrate 101 are stacked. The anode substrate 103, the anode conductive layer 104 and the light emitting layer 105 are stacked in sequence. The cathode conductive layer 102 and the li...

Embodiment 2

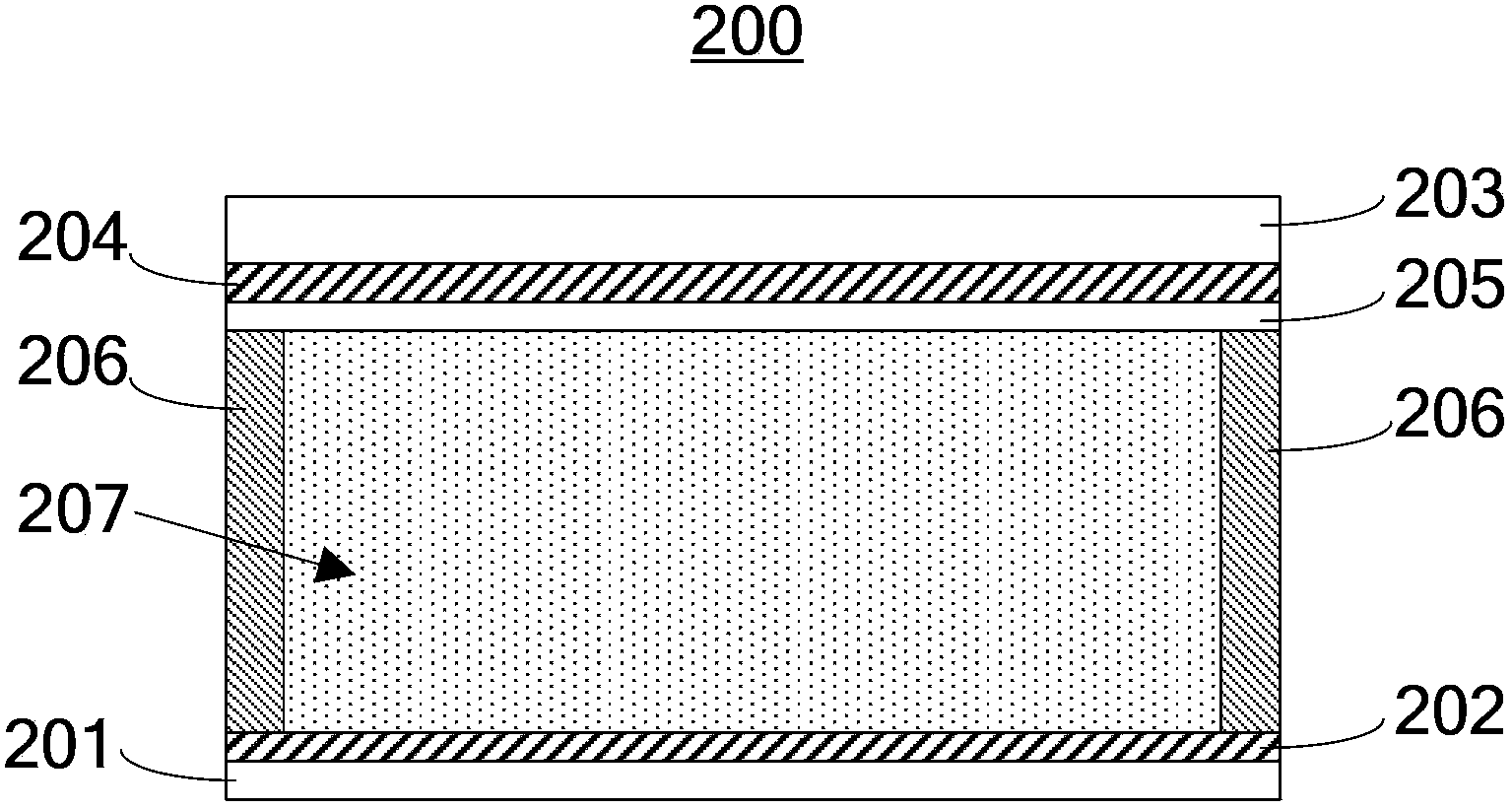

[0048] Such as image 3 The structure of the field emission light source 200 shown is similar to that of the first embodiment. The field emission light source includes a cathode substrate 201, a cathode conductive layer 202, an anode substrate 203, an anode conductive layer 204, a light emitting layer 205, a side wall 206, a sealed cavity 207 and a mixed gas 208 of nitrogen and helium. Wherein, the material of the cathode substrate 201 is transparent ceramics; the material of the cathode conductive layer 202 is an aluminum film with a thickness of 4 μm; the material of the anode substrate 203 is transparent conductive glass; the material of the anode conductive layer 204 is a molybdenum film with a thickness of 4 μm; Layer 205 is Y 2 o 2 S: Eu phosphor.

[0049] The cathode conductive layer 202 and the cathode substrate 201 are stacked. The anode substrate 203, the anode conductive layer 204 and the light emitting layer 205 are stacked in sequence. The cathode conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com