Annular wire stripper

A wire stripper and ring-shaped technology, which is applied in the direction of line/collector parts, electrical components, equipment for dismantling/armouring cables, etc., can solve the problems of increasing electrician labor intensity, reducing labor efficiency, and poor results, and achieves The effect of improving electrician labor efficiency, reducing electrician labor intensity, and being easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

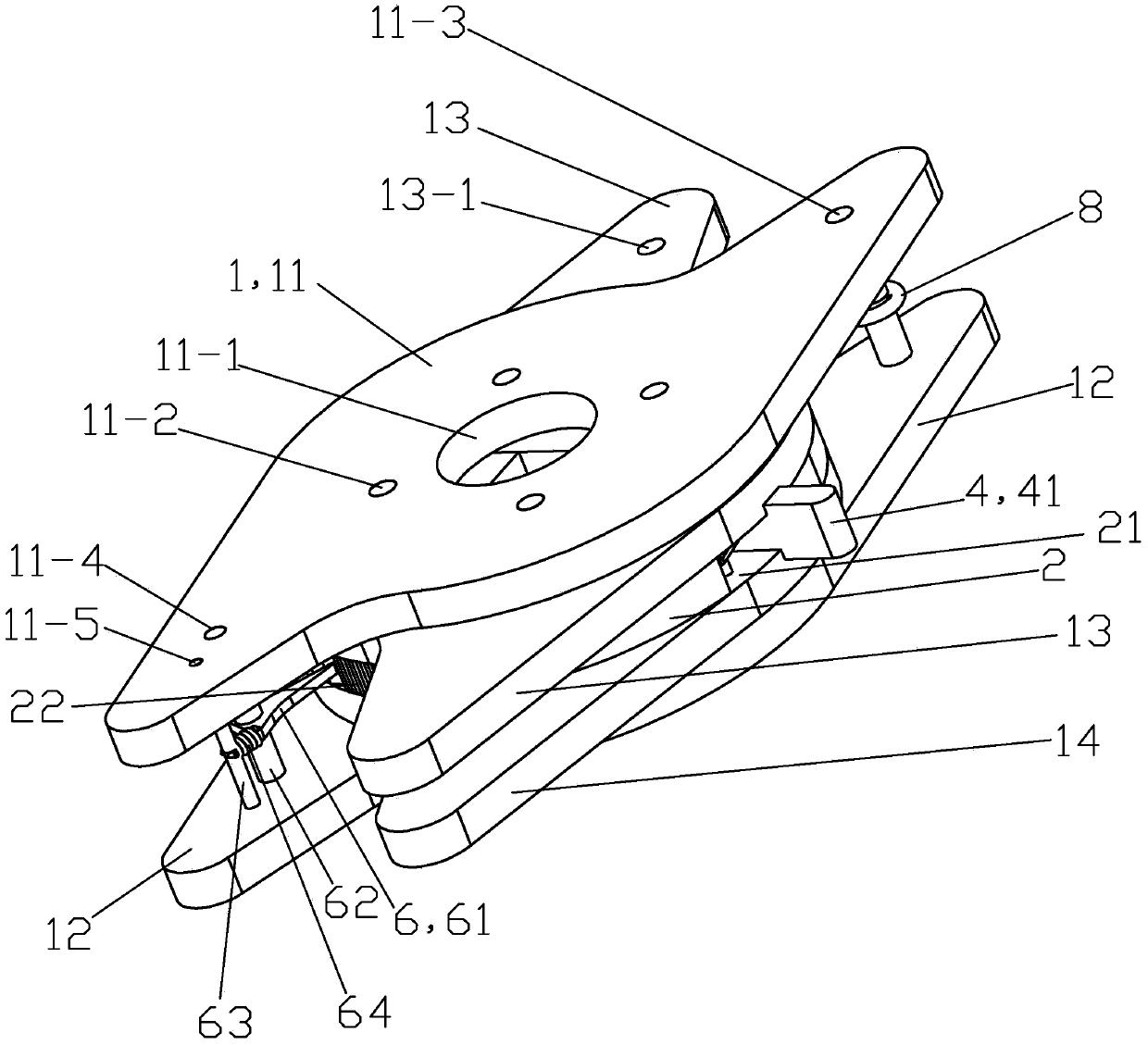

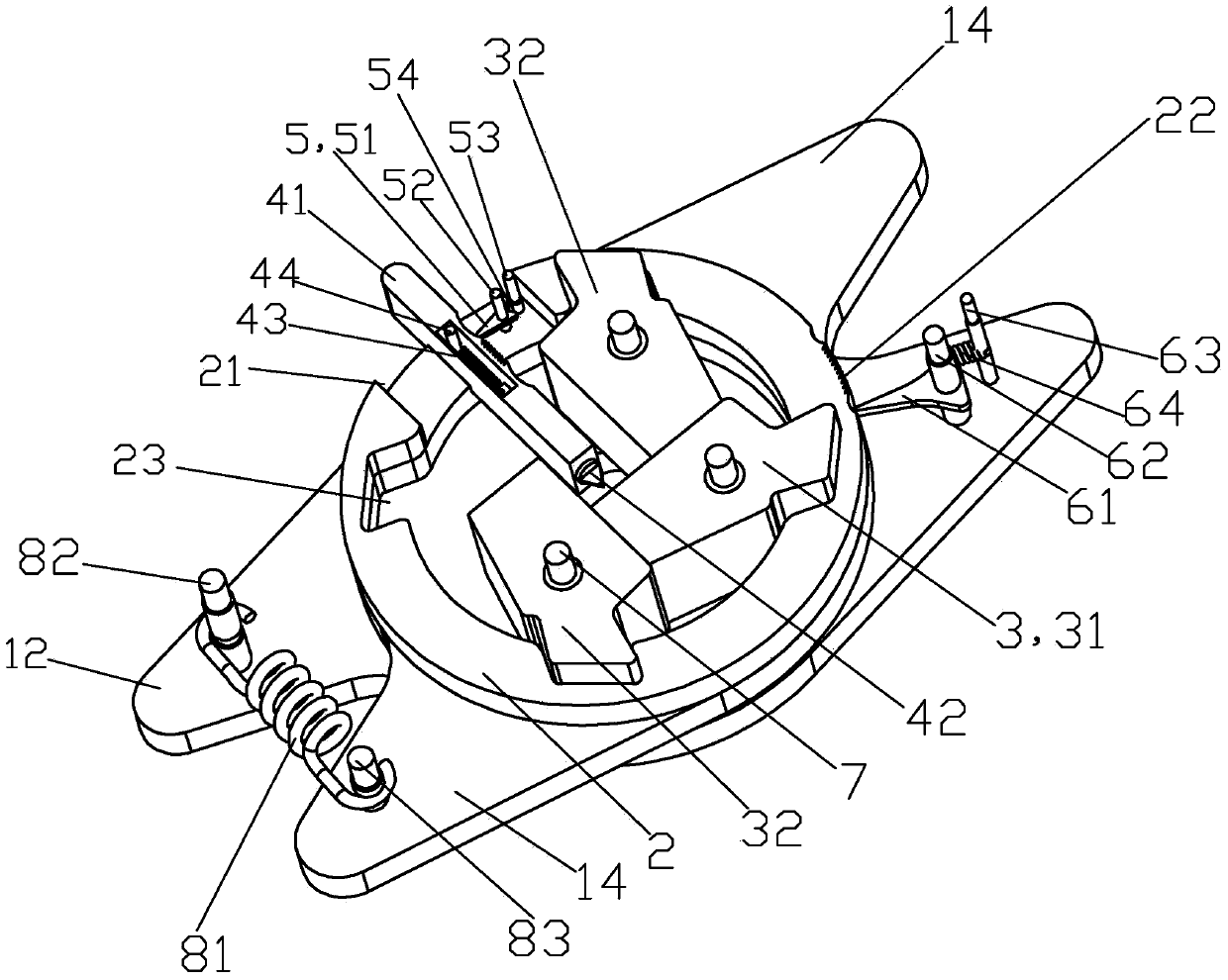

[0034] See figure 1 and figure 2, the ring-shaped wire stripper of this embodiment is mainly composed of a holding pressure assembly 1, a middle mounting part 2, a pliers tooth assembly 3, a ring slitting assembly 4, a cutter head stroke control assembly 5, a pliers tooth braking assembly 6, and a kingpin shaft 7 and the reset assembly 8 are composed.

[0035] The grasping and pressing assembly 1 is mainly composed of a first handle 11 , a second handle 12 , a third handle 13 and a fourth handle 14 .

[0036] The material of the first handle 11 of the holding and pressing assembly 1 is chrome vanadium steel. The first handle 11 is integrally composed of a flat cylindrical body and two substantially arc-shaped grasping parts; the two grasping parts are antisymmetrically arranged on the front and rear sides of the flat cylindrical body. The central position of the oblate cylinder part of the first handle 11 is provided with a circular cable passage hole 11-1 penetrating up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com