Garden high branch saw

A high-branch saw and gardening technology, applied in gardening, gardening tools/equipment, cutting tools, etc., can solve the problems of large deformation of connecting rod components, small axial pressure, and wear of parts, so as to ensure working stability and vibration amplitude The effect of reducing and guaranteeing working accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

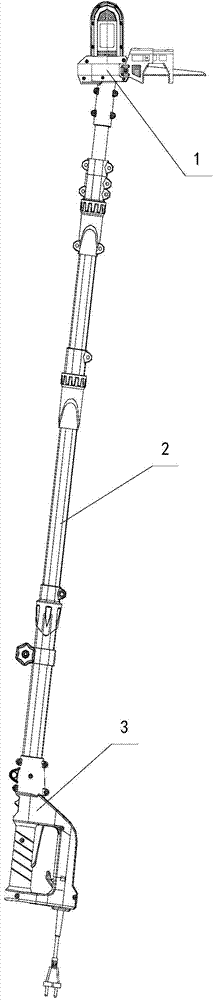

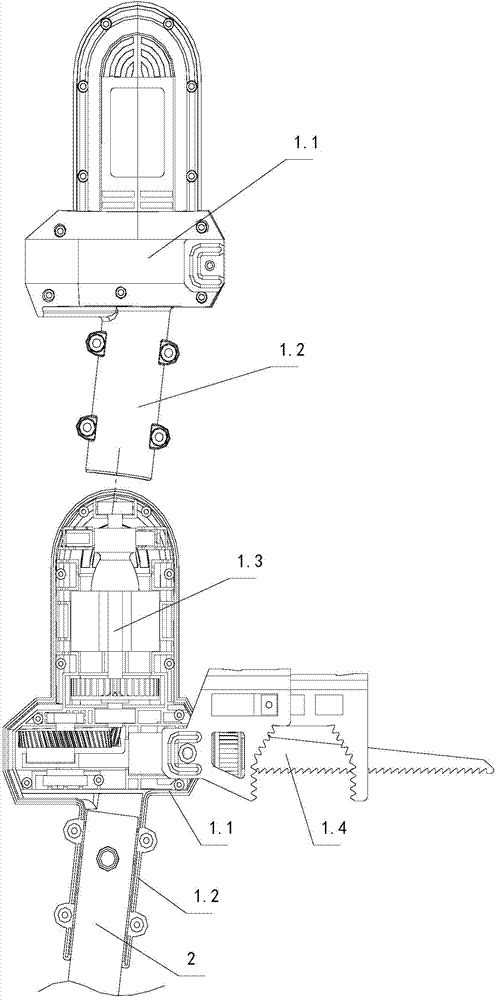

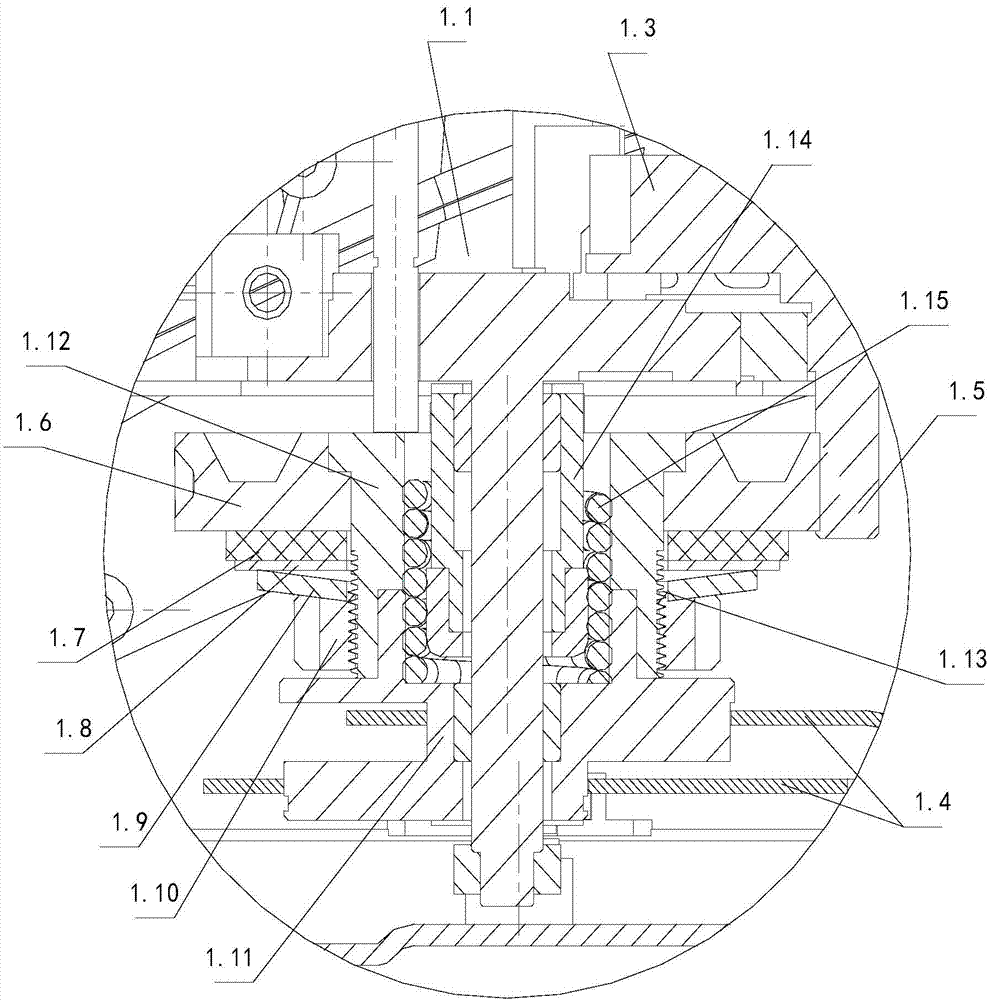

[0022] Depend on figure 1 and figure 2 It can be seen from the structural schematic diagram of the garden high branch saw of the present invention that it includes a saw head assembly 1, a connecting rod assembly 2 and a handle assembly 3, and the saw head assembly 1 and the handle assembly 3 are respectively connected to the upper end of the connecting rod assembly 2 and the handle assembly 3. lower end. The saw head assembly 1 includes a casing, a drive motor 1.3, a transmission mechanism and a saw blade 1.4, and the drive motor 1.3 is connected to the saw blade 1.4 through the transmission mechanism. The casing includes a connecting pipe 1.2 made of engineering plastics and a casing body 1.1, the drive motor 1.3 and the transmission mechanism are installed in the casing body 1.1, and the connecting pipe 1.2 is sleeved on the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com