Chinese herbal medicine oral liquid for treating piglet diarrhea and production method thereof

A technology for piglet diarrhea and production methods, which is applied in the fields of medical formula, drug delivery, antibacterial drugs, etc., can solve the problems of reduced survival rate of piglets, stagnant growth and development, low feed return rate, etc., and achieves simple and easy production process and high product quality. The effect of stable quality and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

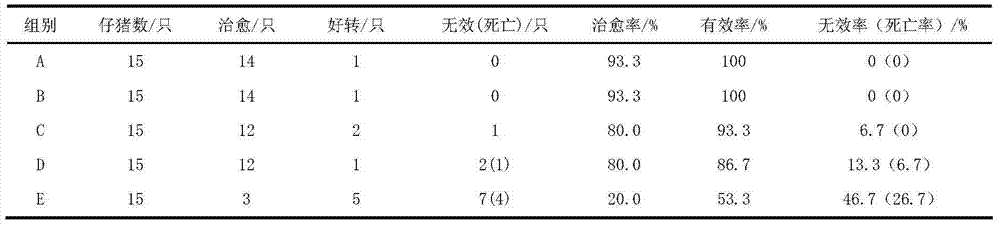

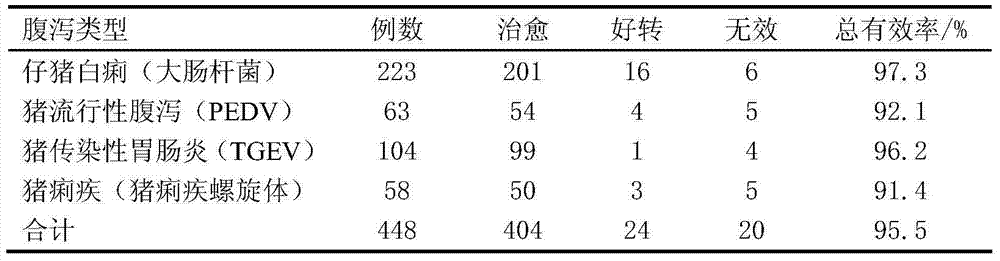

Examples

Embodiment 1

[0021] (1) Preparation of myrtle root extract

[0022] a. Boiled extraction: 50 parts of myrtle root decoction pieces were crushed, added water 5 times according to the weight ratio, boiled for 2 hours, extracted 3 times, collected the medicinal liquid, filtered; the filtrate was vacuum concentrated into an extract at a ratio of 1:4.

[0023] b. Gradient alcohol precipitation and drying: add 95% ethanol to the extract obtained in step a until the final concentration volume fraction of ethanol is 20-30%, let it stand in a cool and dark place for 24 hours, filter the supernatant, and discard the precipitate Continue to add 95% ethanol to the supernatant until the final concentration of ethanol is 70% by volume, let it settle in a cool and dark place for 24 hours, take the supernatant and filter it, and recover the ethanol from the filtrate under reduced pressure; the precipitate is vacuum-dried at 60-70°C, Myrtle root extract A was obtained.

[0024] (2) Extraction of palmatine...

Embodiment 2

[0029] (1) Preparation of myrtle root extract

[0030] a. Boiled extraction: 40 parts of myrtle root decoction pieces were crushed, added water 3 times according to the weight ratio, boiled for 1.5 hours, extracted 2 times, collected the liquid, filtered; the filtrate was vacuum-concentrated into an extract at a ratio of 1:4.

[0031] b. Gradient alcohol precipitation and drying: add 95% ethanol to the extract obtained in step a until the final ethanol concentration volume fraction is 20-30%, let it stand in a cool and dark place for 48 hours, filter the supernatant, and discard the precipitate Continue to add 95% ethanol to the supernatant until the final concentration of ethanol is 30% by volume, let it settle in a cool and dark place for 48 hours, take the supernatant and filter it, and recover the ethanol from the filtrate under reduced pressure; the precipitate is vacuum-dried at 60-70°C, Myrtle root extract A was obtained.

[0032] (2) Extraction of palmatine

[0033] ...

Embodiment 3

[0037] (1) Preparation of myrtle root extract

[0038] a. Boiled extraction: 60 parts of myrtle root decoction pieces were crushed, added water 10 times according to the weight ratio, boiled for 3 hours, extracted 3 times, collected the medicinal liquid, filtered; vacuum concentrated the filtrate into an extract at a ratio of 1:4.

[0039] b. Gradient alcohol precipitation and drying: add 95% ethanol to the extract obtained in step a until the final ethanol concentration volume fraction is 20-30%, let it stand in a cool and dark place for 48 hours, filter the supernatant, and discard the precipitate Continue to add 95% ethanol to the supernatant until the final concentration of ethanol is 30% by volume, let it settle in a cool and dark place for 48 hours, take the supernatant and filter it, and recover the ethanol from the filtrate under reduced pressure; the precipitate is vacuum-dried at 60-70°C, Myrtle root extract A was obtained.

[0040] (2) Extraction of palmatine

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com