Rotor head of rotary wing flying machine and method of manufacturing and assembling such rotor head

A technology of rotorcraft and rotorcraft, applied in aircraft, rotorcraft, transportation and packaging, etc., can solve the problems of air incapacity and flow, and achieve the effects of reducing fuel consumption, small production costs and tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

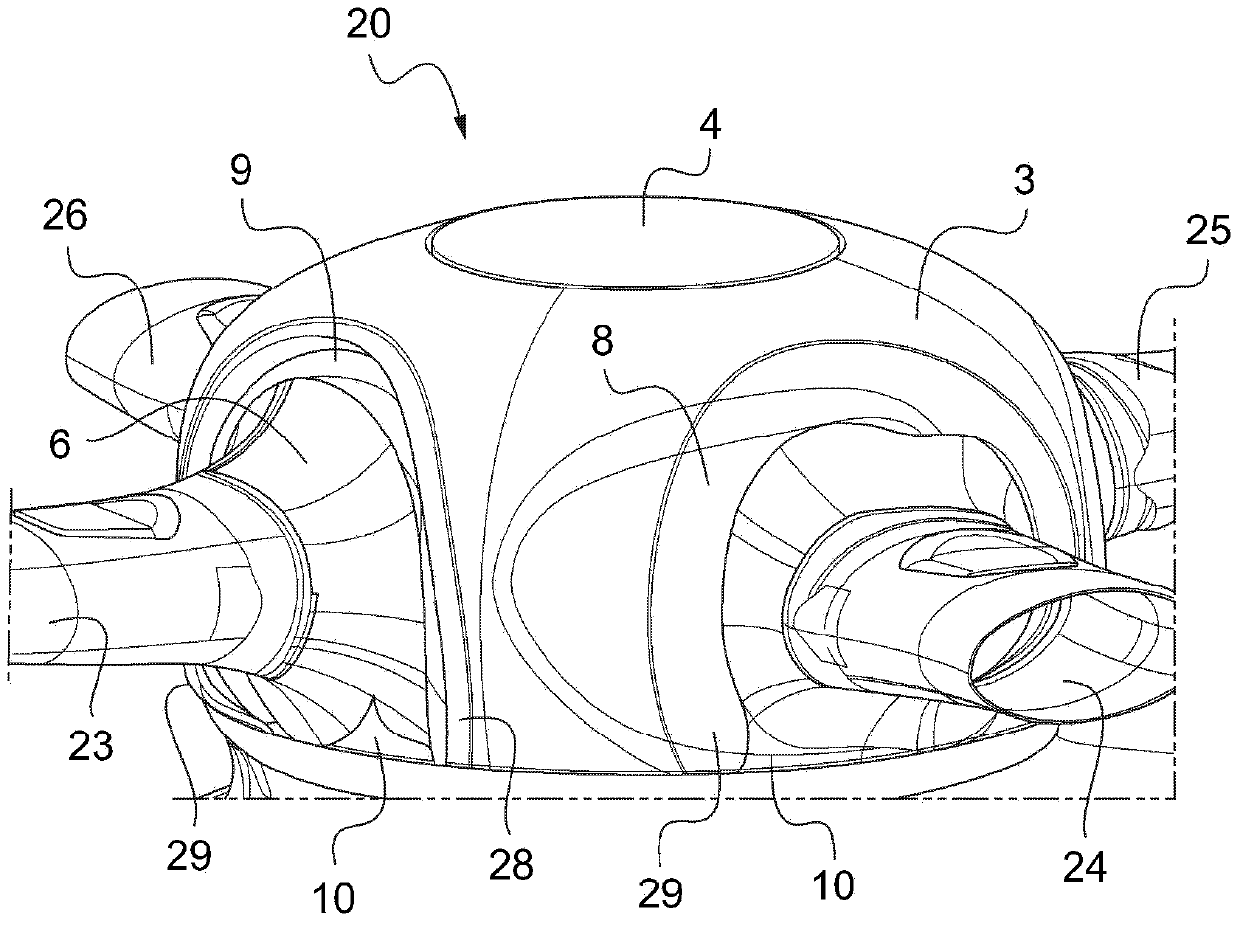

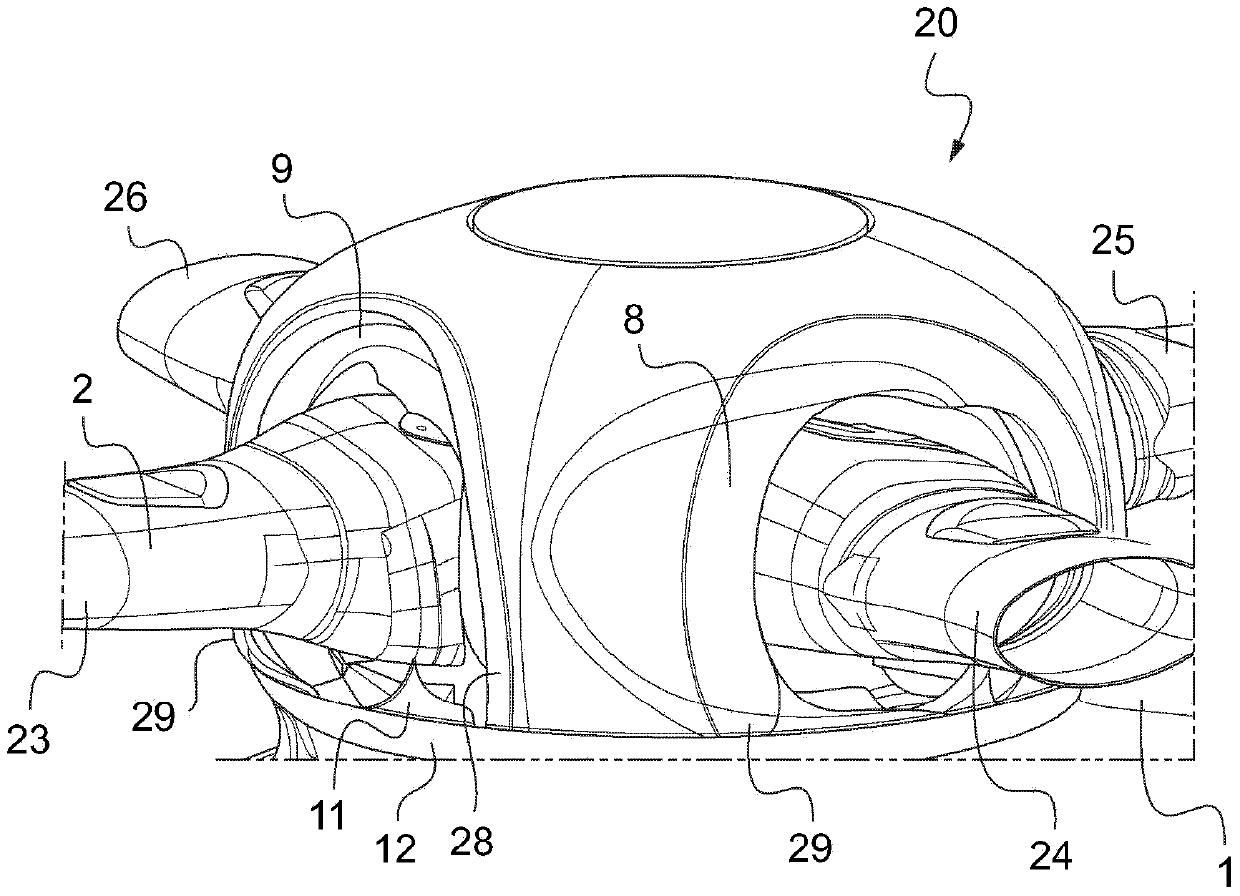

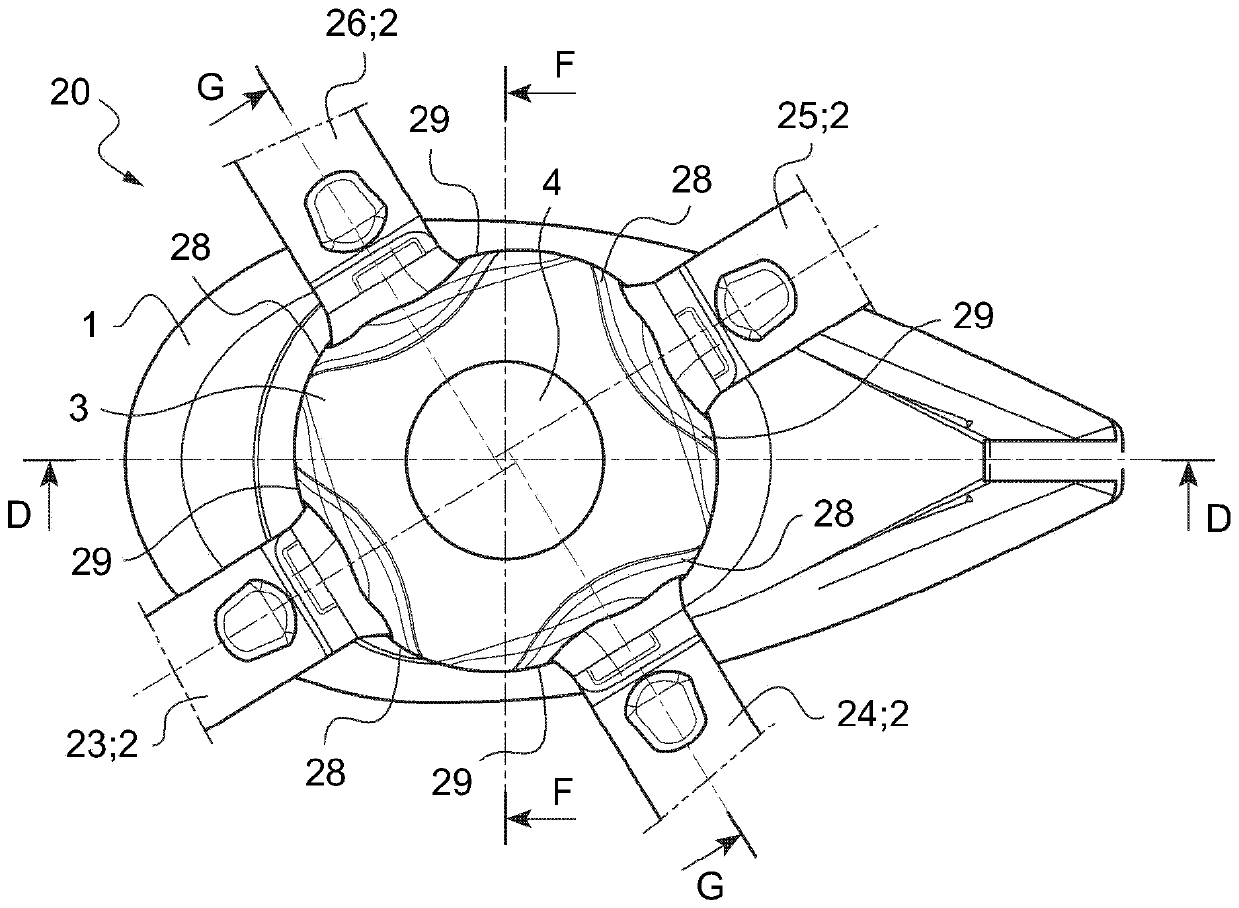

[0061] see Figure 1-4 , the rotor head 20 of the rotorcraft (not shown) is mounted on top of the fuselage (not shown). The rotor main shaft 21 or rotor shaft 22 extends upwards through the main shaft fairing 1 , above the fuselage and into the rotor head 20 . The non-rotating main shaft fairing 1 is provided with an upwardly directed main shaft fairing lip 12 which is coaxial with said rotor main shaft 21 or rotor shaft 22 . The main shaft fairing 1 is made of glass fiber reinforced plastic with a honeycomb core. The spindle fairing lip 12 is made of carbon fiber reinforced plastic.

[0062] The vertical plane is along the axis of the rotor main shaft 21 or rotor shaft 22 , while the orthogonal plane is perpendicular to the axis of said main shaft or shaft of the rotor head of the rotorcraft.

[0063] The four rotor blades 23 - 26 are radially mounted to the rotor main shaft 21 or rotor shaft 22 by means of separable blade attachments for rotation with the rotor head 20 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com