Flame retardant polyurethane hard foam plastic for exterior wall external insulation and preparation method thereof

A technology for rigid foam plastic and external wall thermal insulation, which is applied in the field of building thermal insulation materials and can solve the problems of easy migration of liquid flame retardants and poor technological adaptability of solid flame retardants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

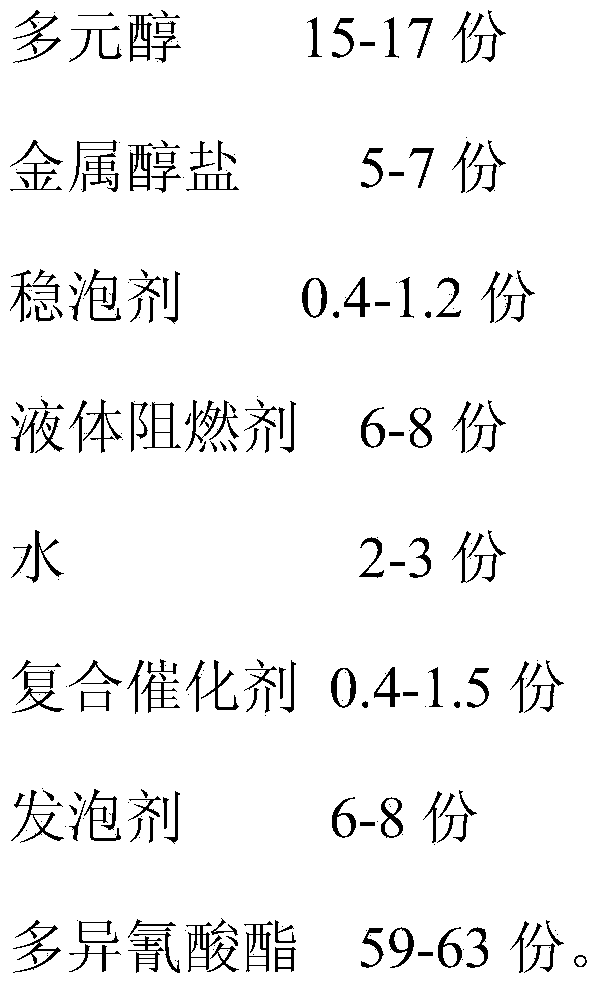

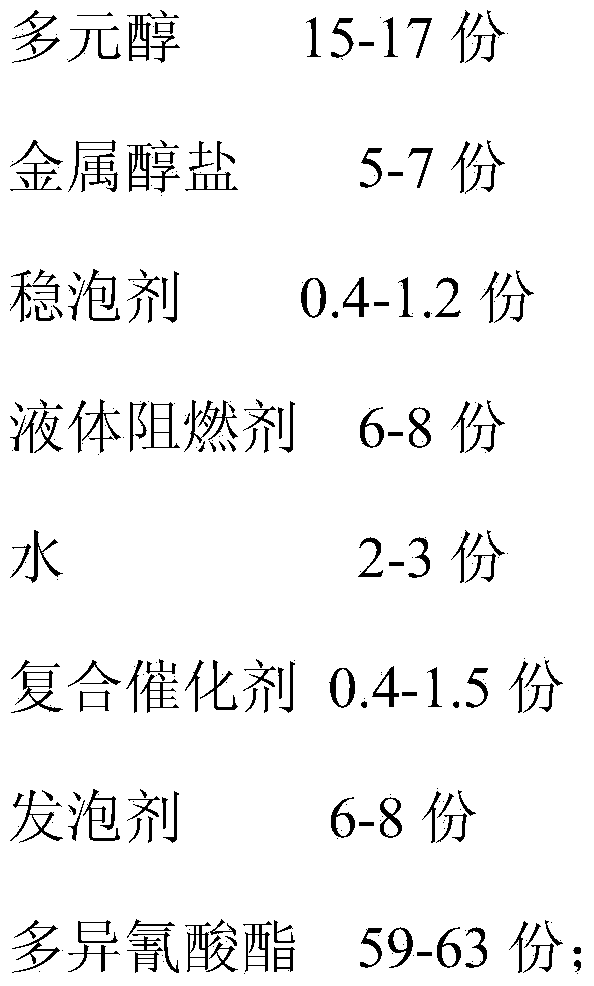

Method used

Image

Examples

Embodiment 1

[0021] Formula composition: polyol NT403A 19.5 parts, hexanediol aluminum salt 3 parts, methyl silicone oil 0.8 parts, TCEP 7 parts, water 2.0 parts, K-151.1 parts, 141b6.6 parts, polyisocyanate PAPI60 parts.

[0022] Mix all other components except PAPI at room temperature for 3 minutes until uniform; then add PAPI, stir at a speed of 5000 rpm for 10 seconds, then pour and freely foam. After completion, the flame-retardant Polyurethane rigid foam.

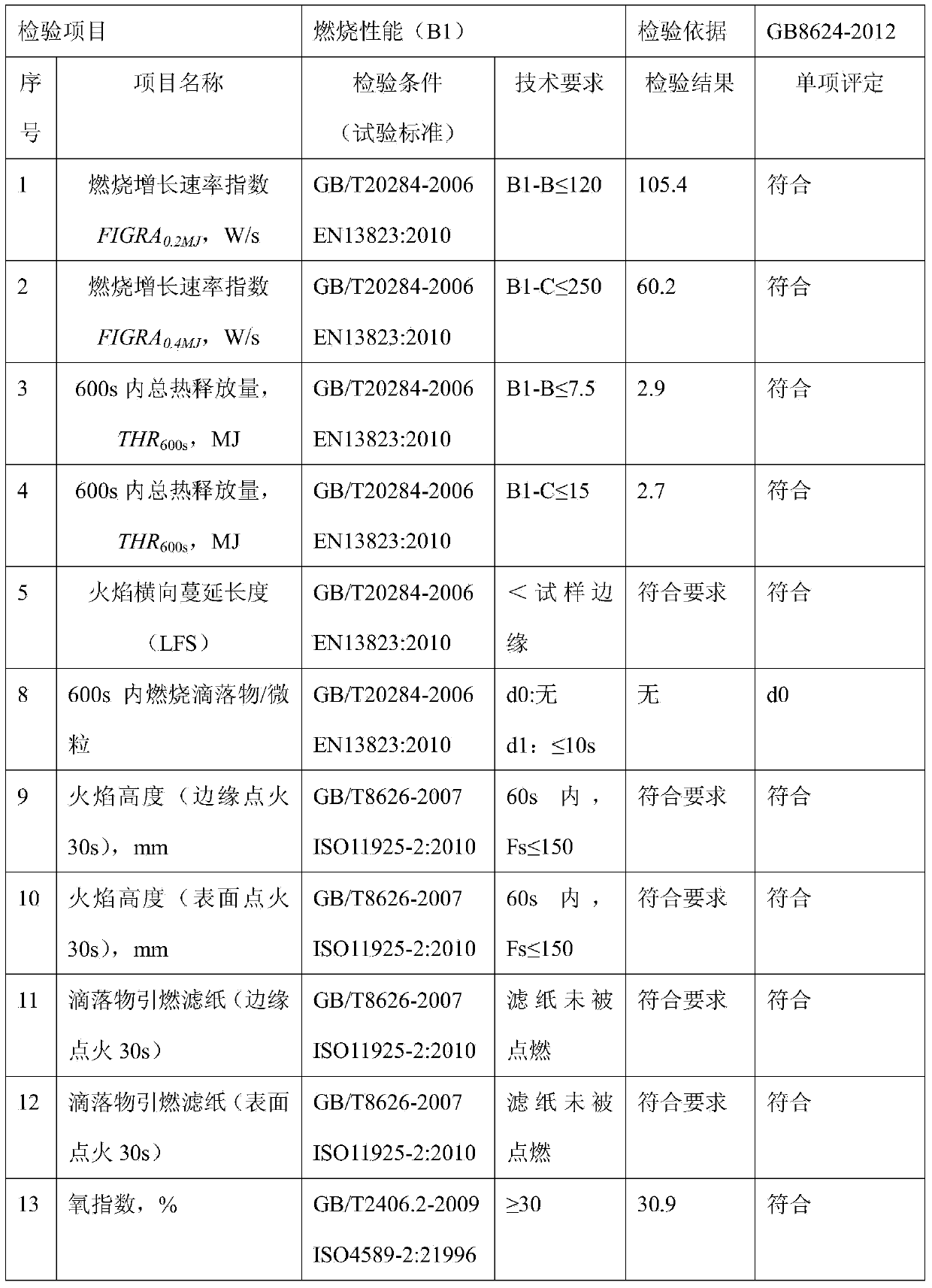

[0023] According to the GB8624-2012 standard test, the combustion performance of the prepared foamed plastics is shown in Table 1.

[0024] Table 1 NT403A formula foam combustion performance

[0025]

Embodiment 2

[0027] Formula composition: the mass content of polyol QZ450L is 19.5 parts, 3 parts of hexanediol aluminum salt, 1.1 parts of methyl silicone oil, 7 parts of TCPP, 2.0 parts of water, 1.0 parts of PC-8, 6.4 parts of 141b, 60 parts of polyisocyanate PAPI.

[0028] Mix all other components except PAPI at room temperature for 3 minutes until uniform; then add PAPI, stir at a speed of 5000 rpm for 10 seconds, then pour and freely foam. After completion, the flame-retardant Polyurethane rigid foam.

[0029] According to the GB8624-2012 standard test, the properties of the prepared foam plastics are shown in Table 2.

[0030] Table 2QZ450L formula foam properties

[0031]

[0032]

Embodiment 3

[0034] Formula composition: the mass content of polyol QZ450L is 18 parts, 4 parts of hexanediol aluminum salt, 1.1 parts of methyl silicone oil, 7 parts of TCPP, 2.5 parts of water, 1.0 parts of PC-8, 6.4 parts of 141b, and 60 parts of polyisocyanate PAPI.

[0035] Mix all other components except PAPI at room temperature for 3 minutes until uniform; then add PAPI, stir at a speed of 5000 rpm for 10 seconds, then pour and freely foam. After completion, the flame-retardant Polyurethane rigid foam.

[0036] Tested according to the GB8624-2012 standard, the properties of the prepared foam plastics are shown in Table 3.

[0037] Table 3 QZ450L formula foam properties

[0038]

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com