Preparation method of energy-saving overhead wire

An energy-saving overhead wire and wire technology, which is used in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of low wire transmission efficiency and unstable temperature, and achieve the effect of increasing transmission capacity and improving transmission capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

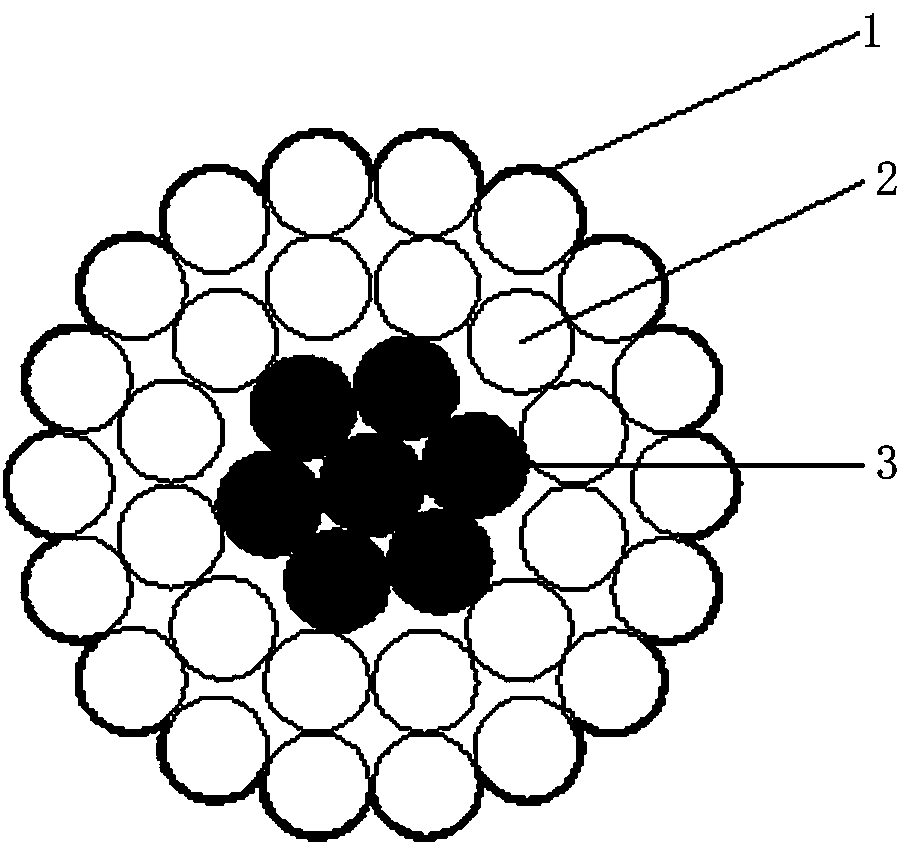

[0022] detailed description: Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] The invention provides a method for preparing an energy-saving overhead wire. The steps of the method are as follows:

[0024] 1) Mix PEVE fluorocarbon resin and butyl acetate at a mass ratio of 1 to 1.2:1 and disperse with a high-speed disperser for about 10 minutes, then grind the mixture with a sand mill until the fineness reaches 25 to 30 μm to obtain a fluorocarbon resin dispersion liquid;

[0025] 2) Add hexamethylene diisocyanate biuret to the above-prepared fluorocarbon resin dispersion at a mass ratio of 4 to 5:1, fully stir and mix evenly with a high-speed disperser to obtain a fluorocarbon-based coating;

[0026] 3) Use ethanol (alcohol) to clean the wire online to remove surface stains, etc.;

[0027] 4) Use compressed air to spray the paint on the wire at a speed of 15m / min, and the thickness of the paint layer is 30μm.

[002...

Embodiment 1

[0031] 1) Mix PEVE fluorocarbon resin and butyl acetate at a mass ratio of 1:1 and disperse with a high-speed disperser for about 10 minutes, then grind the mixture to a fineness of 25 μm with a sand mill to obtain a fluorocarbon resin dispersion.

[0032] 2) Add hexamethylene diisocyanate biuret to the above-prepared fluorocarbon resin dispersion at a mass ratio of 4:1, fully stir and mix evenly with a high-speed disperser to obtain a fluorocarbon-based coating.

[0033] 3) Use ethanol (alcohol) to clean the wire online to remove surface stains, etc.

[0034] 4) Use compressed air to spray the paint on the wire at a speed of 15m / min, and the thickness of the paint layer is 30μm.

[0035] 5) Dry the wire at 30°C.

[0036] 6) Pack the dried wires and put them on the disk.

Embodiment 2

[0038] 1) Mix PEVE fluorocarbon resin and methyl isobutyl ketone at a mass ratio of 1.2:1 and disperse with a high-speed disperser for about 10 minutes, then grind the mixture with a sand mill until the fineness reaches 30 μm to obtain a fluorocarbon resin dispersion .

[0039] 2) Add hexamethylene diisocyanate biuret to the above-prepared fluorocarbon resin dispersion at a mass ratio of 5:1, fully stir and mix evenly with a high-speed disperser to obtain a fluorocarbon-based coating.

[0040] 3) Use ethanol (alcohol) to clean the wire online to remove surface stains, etc.

[0041] 4) Use compressed air to spray the paint on the wire at a speed of 15m / min, and the thickness of the paint layer is 30μm.

[0042] 5) Dry the wire at 80°C.

[0043] 6) Pack the dried wires and put them on the disk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com