Isopropanol urea dewaxing method

A technology of isopropanol and dewaxing, which is applied in the field of dewaxing, can solve problems such as pipeline blockage, low water temperature requirements, and reduced heat exchange effect, and achieve the effects of uniform distribution, uniform heat exchange, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

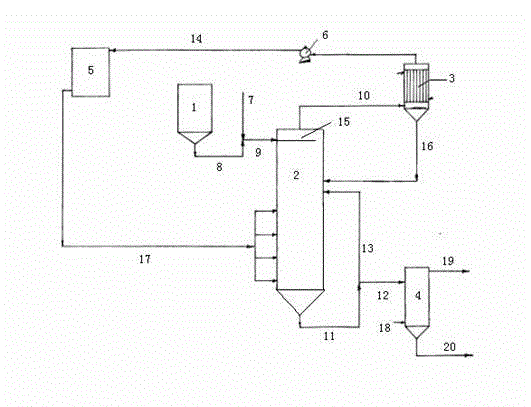

Method used

Image

Examples

Embodiment 1

[0024] The raw material oil used in this example is the second-line distillate of Daqing, the cooling medium is liquefied petroleum gas, the urine composition and process conditions are shown in Table 1, and the obtained results are shown in Table 2.

[0025] Table 1 Properties of raw oil

[0026] project data, Density (20°C), g cm -3 0.8182 freezing point, ℃ 3 Flash point (closed mouth), ℃ 75 Acid value, mgKOH·g -1 0.65 S, μg g -1 942 N, μg·g -1 125 n-alkanes, % 45.6 Distillation range, ℃ Initial distillation / 10% 178 / 229 30% / 50% 252 / 272 70% / 90% 294 / 320 95% / dry point 330 / 342

[0027] Table 2 Composition of isopropanol urine solution

[0028] project data Urea, wt% 40 Isopropanol, wt% 40 Water, wt% 20

[0029] Table 3 embodiment technological conditions

[0030] Feed temperature, °C 70 Final reaction temperature, ℃ 28 urine oil ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com