Cooling assembly for turbine outer ring

A technology for cooling components and outer rings, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of not mentioning outer ring wear protection, single air film hole channel and shape, and few types of cooling methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

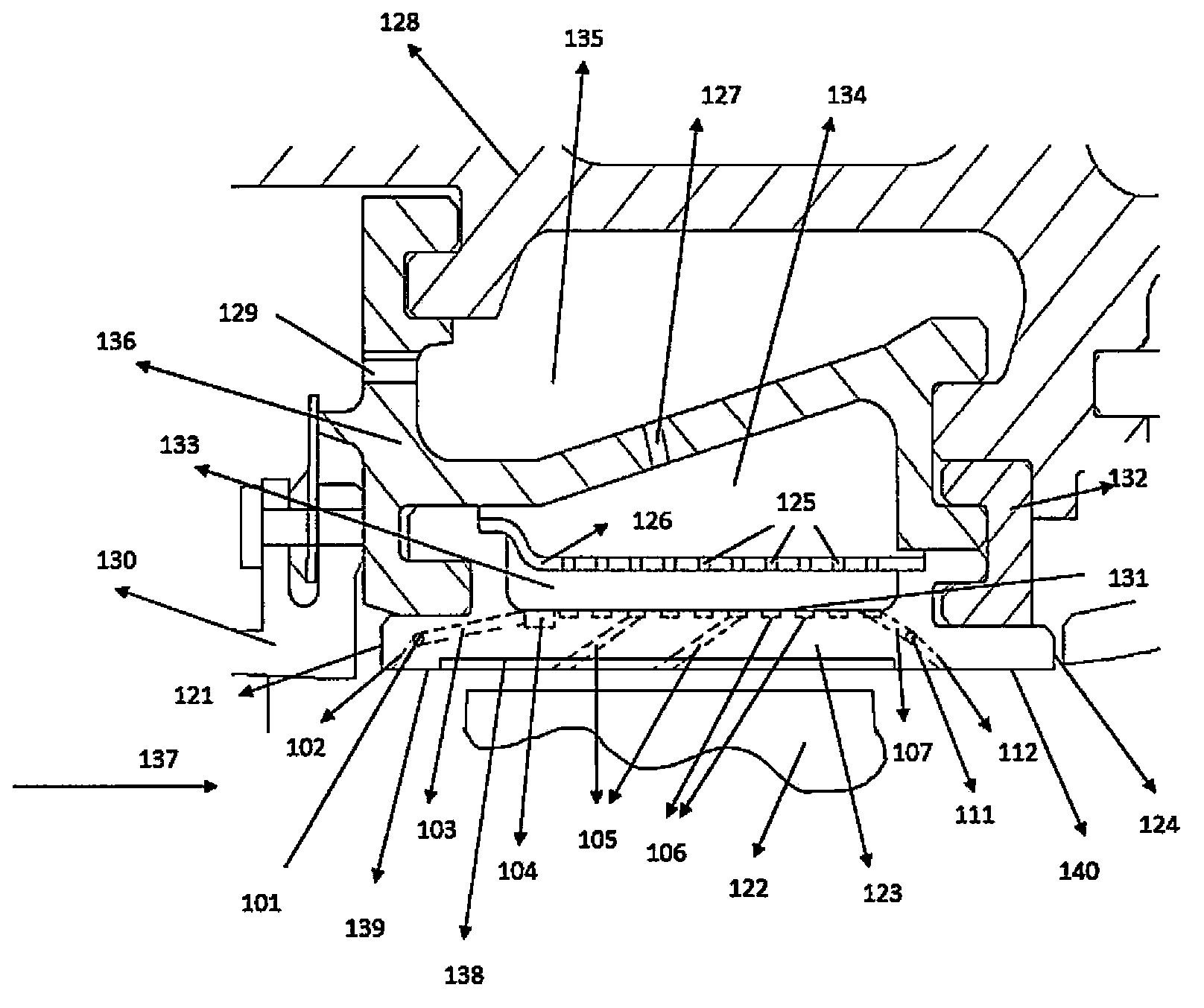

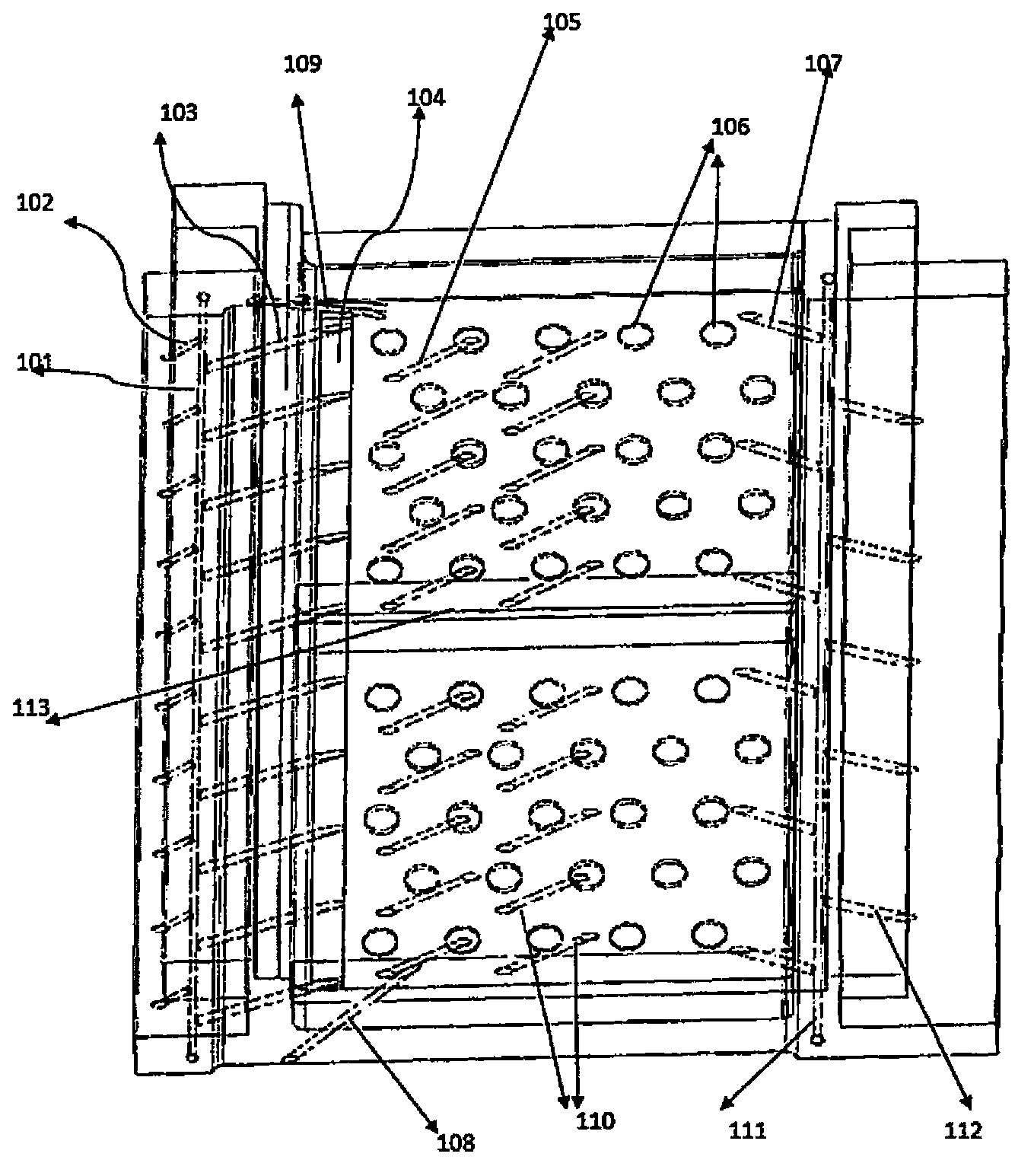

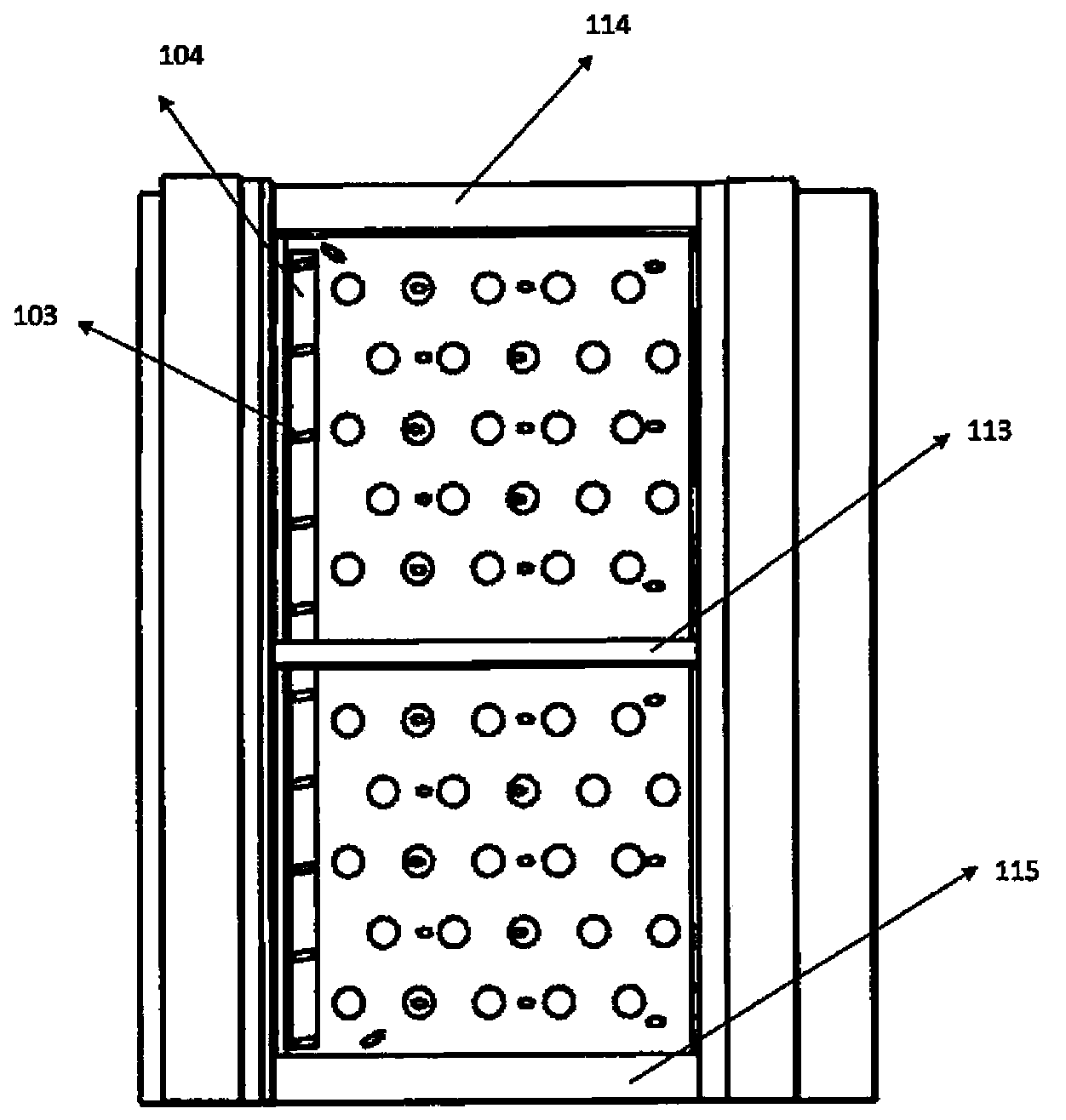

[0073] Such as figure 1 and figure 2 As shown, the present invention is a cooling assembly for combined cooling applied to the outer ring of a gas turbine. The invention divides the 360° circumferential direction of the engine turbine outer ring into several parts on average, and the cooling of each part is the same.

[0074] The outer ring base 123 is an arc-shaped structure formed by rotating around the center line of the engine, and connects the circumferential front end surface 121 located upstream of the air flow of the main gas passage 137 and the circumferential rear end surface 124 located downstream of the air flow. The entire outer ring is composed of 42 identical and circumferentially adjacent outer ring substrates. The arc-shaped interface shared by the impact chamber 133 and the outer ring is defined as the outer surface 131 of the outer ring (excluding the gas-collecting groove and pit structure arranged at this position of the outer ring base body), the arc o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com