Carbon dioxide solid sublimation device

A carbon dioxide, high-pressure carbon dioxide technology, applied in sublimation, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of improving heat exchange efficiency, energy utilization efficiency, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

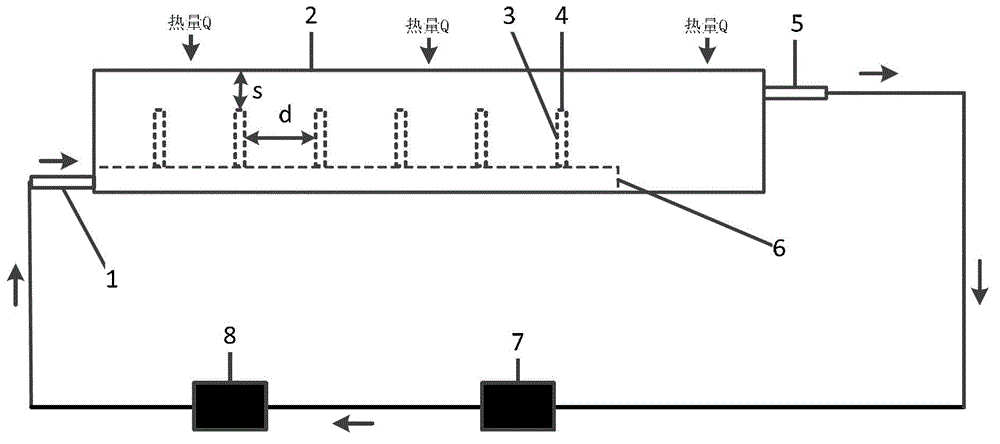

[0042] Such as figure 1 Shown is a system diagram of an example of the invention.

[0043] In this implementation example, the device of the present invention is a part of the entire carbon dioxide cross-triple-point refrigeration system (the part indicated by labels 1 to 6), and the high-pressure and low-temperature carbon dioxide liquid output by the condensing system 7 flows into the sublimator from the inflow pipe 1 The inner pipe 6, the high-pressure and low-temperature carbon dioxide liquid in the inner pipe 6 of the sublimator expands through the nozzle 3 to the low-pressure outer pipe 2 of the sublimator to produce solid carbon dioxide, and the solid carbon dioxide is sprayed onto the heat exchange surface of the outer pipe 2 of the sublimator, and The heat exchange surface of the sublimator outer tube 2 is in full contact with the heat source for sublimation, and the remaining carbon dioxide solids after sublimation sink into the heat exchange surface of the sublimato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com