A mechanical disturbance driven submerged liquid-cooled sintered capillary core copper-based heat sink

A technology of heat dissipation device and capillary core, which is applied in furnace cooling, indirect heat exchanger, maintenance of heating chamber, etc., can solve the problems of uneven and insufficient cooling medium replenishment, difficulty in separation of phase change bubbles, etc., and achieves an increase in the contact area. Large, prevent the effect of local hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following embodiments of the present invention will be further described in detail:

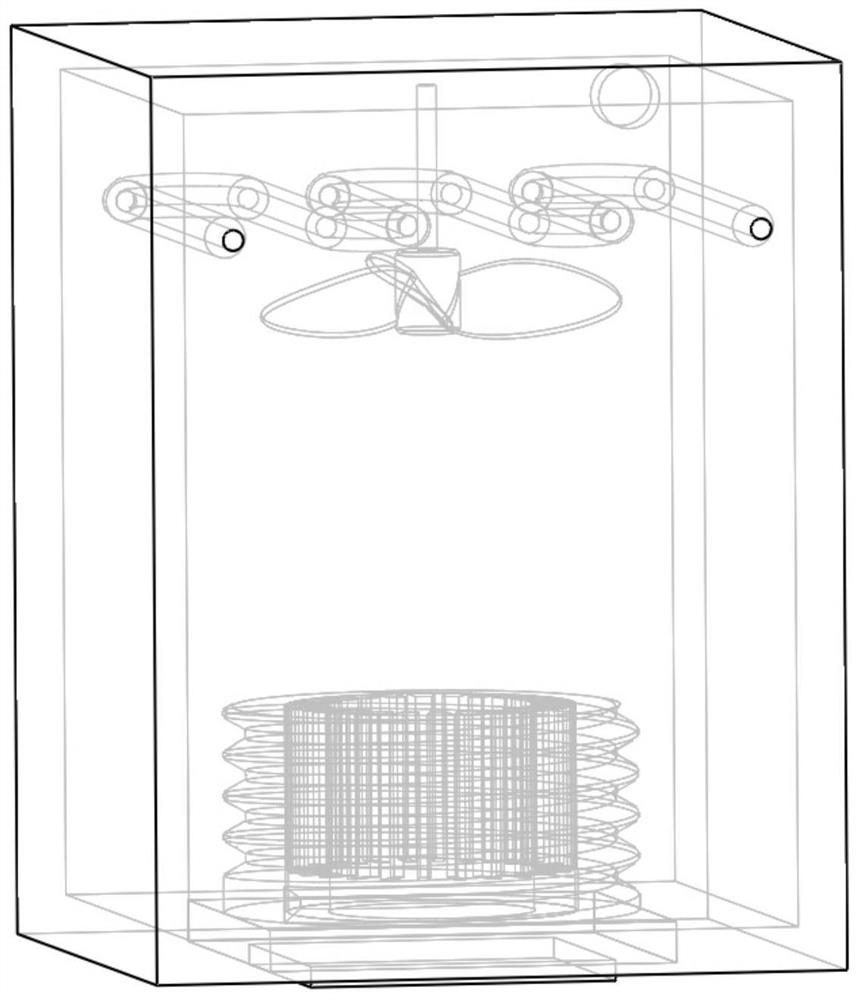

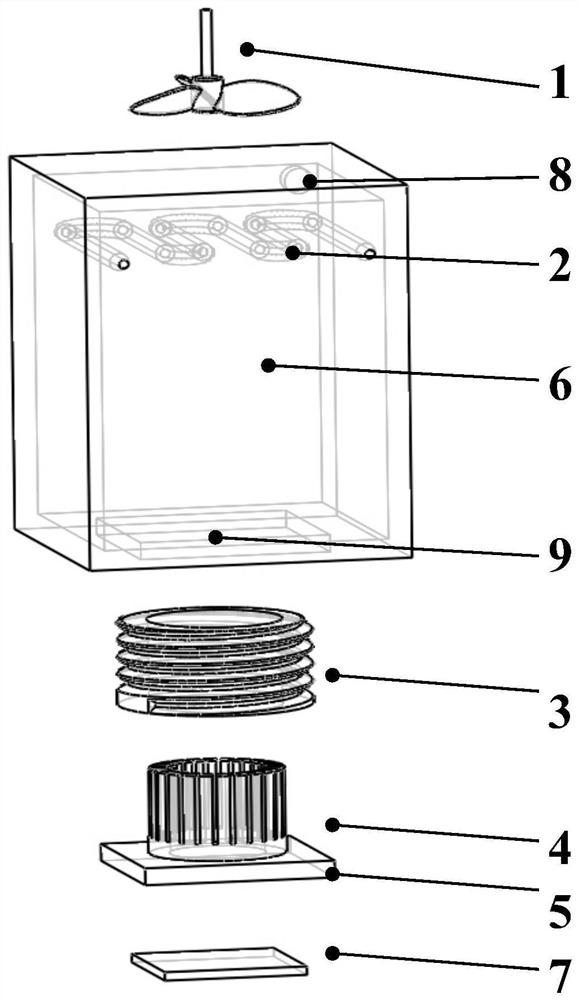

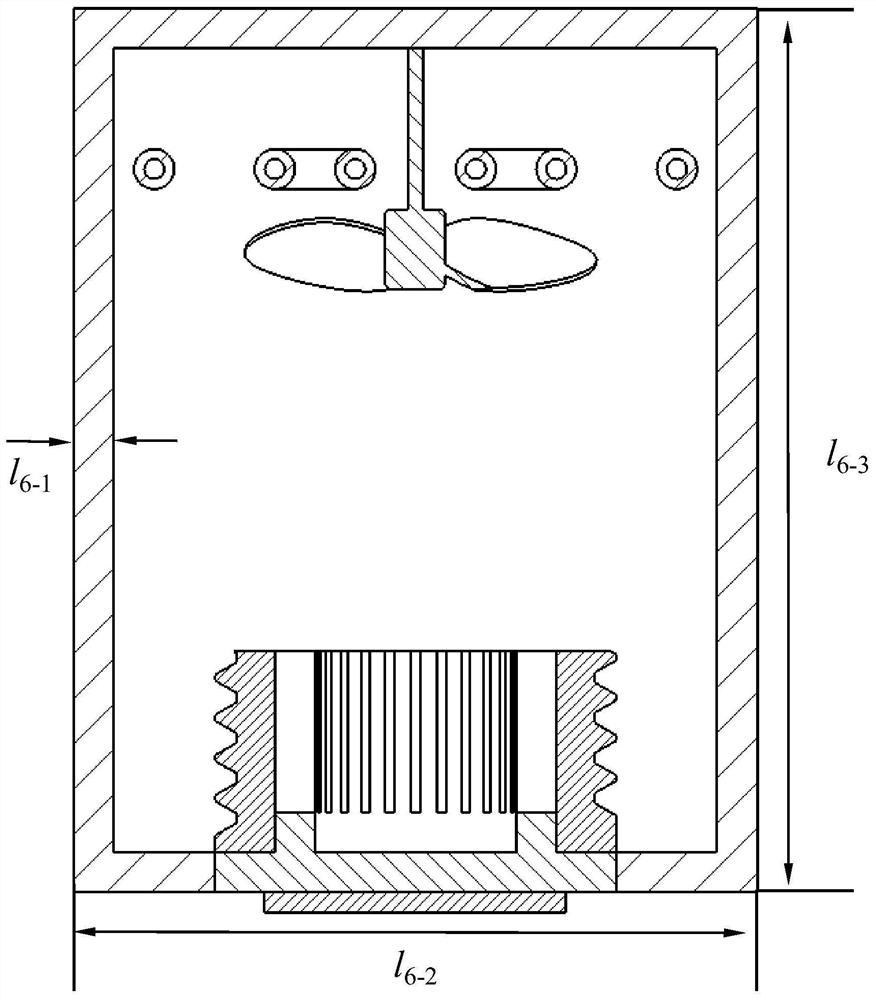

[0036] A kind of mechanical disturbance drive immersion type liquid cooled sintered capillary core copper-based heat dissipation device, such as Figure 1-1 、 1-2 Shown, including disturbance vane 1, cooling coil 2, spiral sintered capillary core 3, annular rib group 4, square vapor plate 5, external cavity 6, heat dissipation chip 7, external cavity 6 with rehydration port 8 and parts opening 9.

[0037]The device can be divided into three parts: mechanical power strengthening heat transfer part based on disturbance blade 1; The surface structure strengthens the heat transfer part and other auxiliary parts represented by spiral sintered capillary core 3, annular rib group 4, and square vaporized plate 5. The mechanical power of the disturbing blade 1 will effectively drive the flow of liquid in the cavity when it is in operation, promote the mixing and exchange of heat with the cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com