Universal multispectral zero correction instrument for guns

A zero-position correction, multi-spectral technology, used in weapon accessories, offensive equipment, weapon testing, etc., to reduce combat preparation time, improve shooting quality, and reduce security requirements.

Active Publication Date: 2014-05-14

河南华阳装备制造有限公司

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it solves the problem of parallelism between the axis of the bore and the optical axis of the scope, the wear and tear of the bore has a great influence on the ballistic. After correcting the zero position with this correction mirror, the live ammunition shooting still cannot hit the bullseye, and live ammunition shooting needs to be corrected. For the white light or low-light or infrared sights prepared for the same firearm, the zero position and live ammunition shooting correction need to be corrected respectively; especially the low-light sights need to shoot live ammunition at night, and the infrared sights need special heat radiation target boards and shooting ranges ; For different firearms, different calibrators are needed, so the calibrator varieties are many and miscellaneous, and the user's carrying weight has been increased, so there is a defect that cannot be popularized and applied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

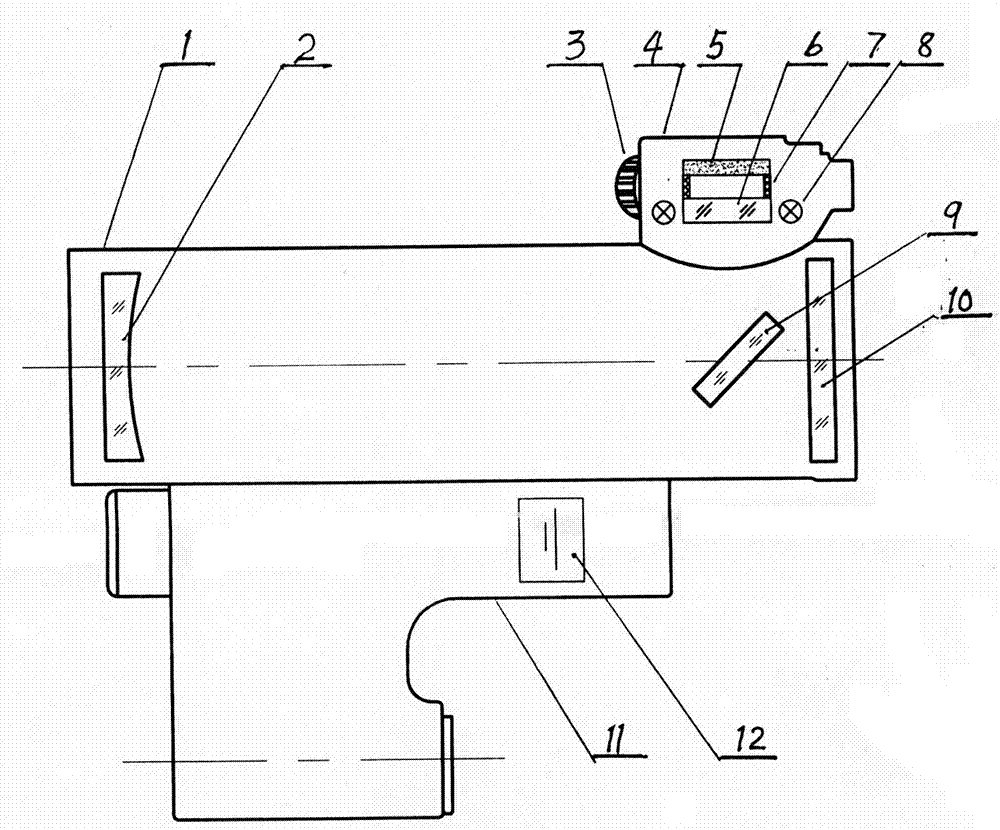

The invention belongs to the field of gun correction and provides a universal multispectral zero correction instrument for guns. The universal multispectral zero correction instrument is characterized in that a division assembly is arranged on a lens cone assembly and comprises a thermal radiation source light source, a multispectral division plate, a division plate movement micrometer mechanism and a displacement displayer. The universal multispectral zero correction instrument for guns can perform multispectral universal correction and perform firing practice zero correction without special shoot ranges in daytime through glimmer and infrared gun sights, therefore, labor intensity of combatant is reduced, security requirements are reduced, correction live ammunition is saved, and quick reaction capability and shoot quality of troops are increased.

Description

Technical field: [0001] The invention belongs to the technical field of gun calibration, and in particular relates to a universal multi-spectral zero calibration instrument for guns. Background technique: [0002] After all kinds of sights are installed on the firearm, they must be zero-calibrated. The traditional method is to correct the zero position through multiple live ammunition shooting and repeated corrections. This method consumes a lot of material and manpower, and is labor-intensive and time-consuming. Later, someone made a single white light or low light or infrared optical axis zero correction device, which is composed of a collimating mirror and an insertion shaft that provides an infinite distance target. Although it solves the problem of the parallelism between the axis of the bore and the optical axis of the scope, the wear and tear of the bore has a great influence on the trajectory. After correcting the zero position with this correction mirror, the liv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F41A31/00

Inventor 张晓慧陈建军贾少华吕涛刘正孔繁欣武向党李增王磊

Owner 河南华阳装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com